Fireproof and smash-proof mobile intelligent bullet cabinet

A mobile bullet cabinet technology, applied in the field of bullet cabinets, can solve the problems of no fixed protection device for guns, easy slipping of guns, inconvenient movement, etc., and achieve the effect of increasing the scope of application, easy placement and access, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

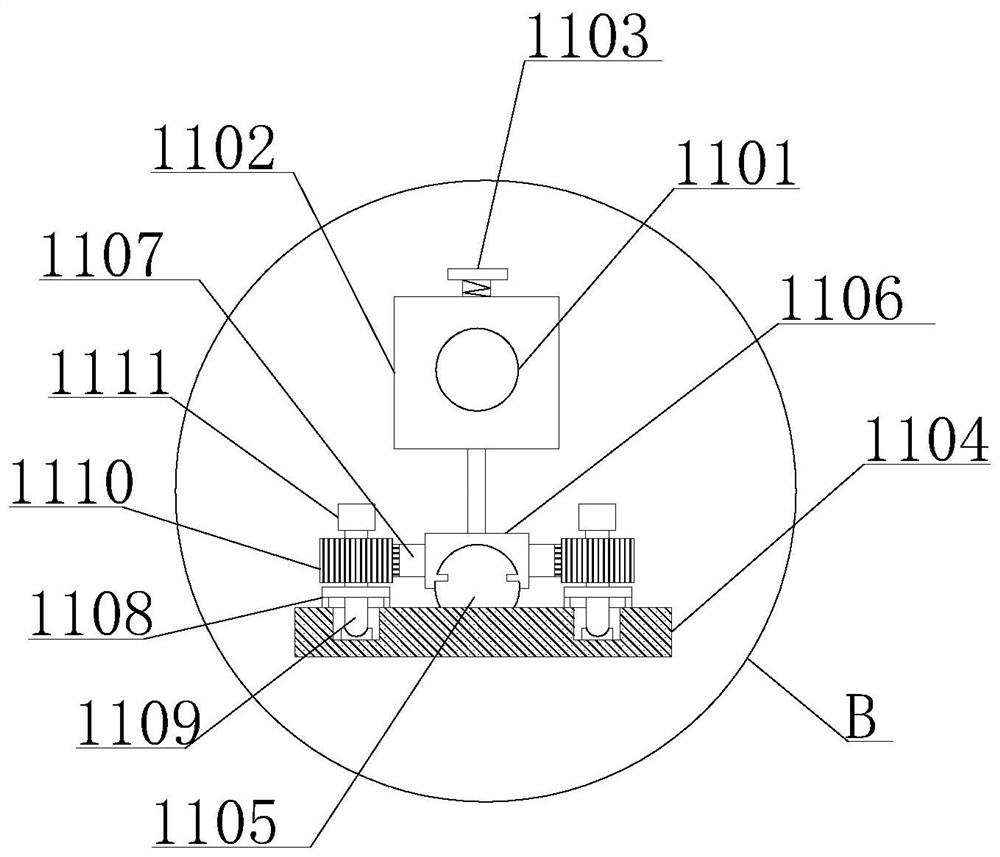

[0032] Embodiment 1, the bottom of the adjustment block 1102 is fixedly installed with a connecting rod. By moving the adjustment block 1102, the slider 1106 can be driven to slide on the surface of the slide rail 1105, and the gear and the rotating rod 1109 can be driven to rotate through the rack 1107, thereby adjusting the clamping arm 1111 dimensions.

Embodiment 2

[0033] In Embodiment 2, a locking knob is provided inside the adjusting block 1102 . When the adjusting block 1102 is moved to a suitable position, the locking knob 1103 is tightened to fix it, so that the clamping arm 1111 can firmly clamp the firearm.

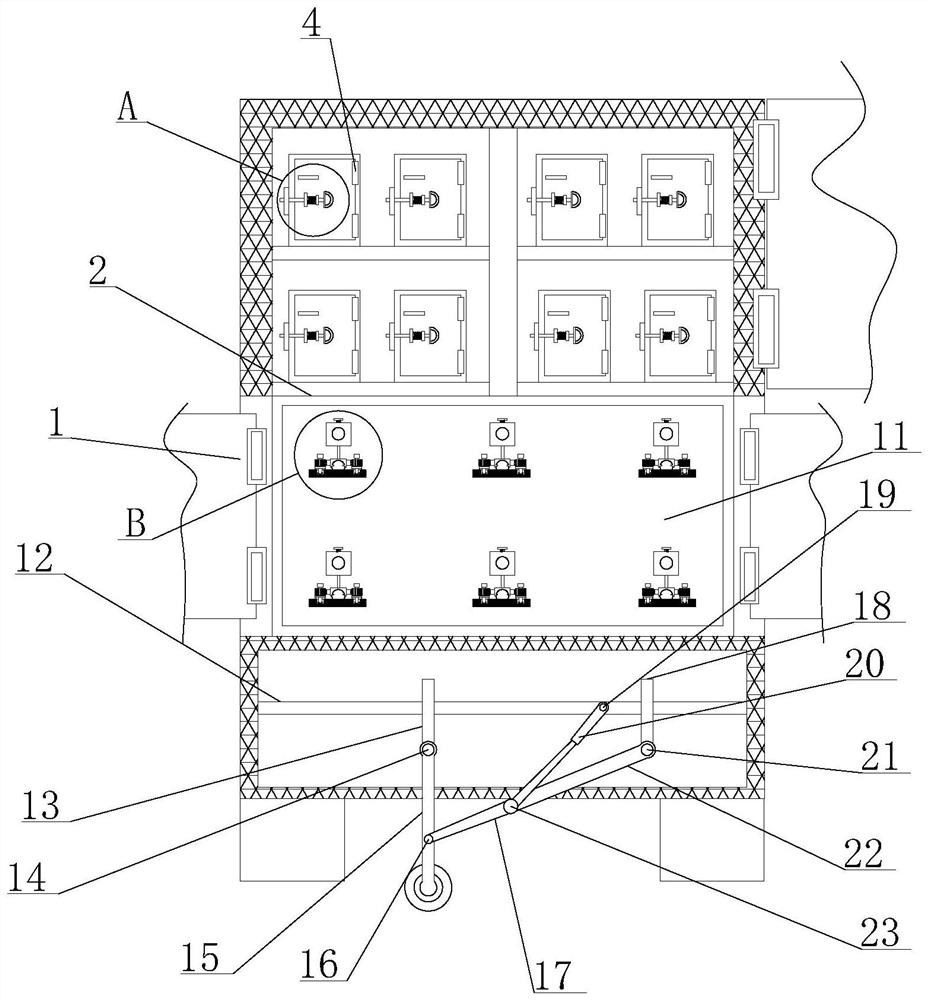

[0034] Working principle: When the cylinder 20 is stretched out, it drives the third connecting rod 22 to rotate counterclockwise outside the fourth rotating shaft 21, the cylinder 20 rotates counterclockwise outside the third rotating shaft 19, and the first connecting rod 15 rotates clockwise outside the first rotating shaft 14 , the second connecting rod 17 rotates clockwise outside the fifth rotating shaft 23. At this time, the roller is released to facilitate movement. When the cylinder 20 is withdrawn, it drives the third connecting rod 22 to rotate clockwise outside the fourth rotating shaft 21. The outside of the rotating shaft 19 rotates clockwise, the first connecting rod 15 rotates counterclockwise outside the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com