A Physical Separation System for Metal Impurities in Broken Waste Glass

A technology of metal impurities and physical separation, which is applied in the field of solid waste recycling, can solve the problems of incomplete purification of impurities and low metal removal rate of waste glass, and achieve the effects of efficient recycling, avoiding secondary pollution, and avoiding waste water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

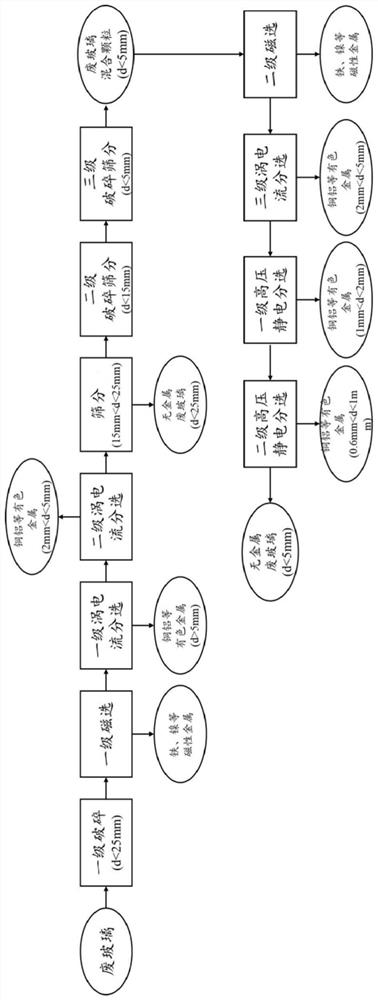

[0027] Example 1 A Physical Separation System for Metal Impurities in Broken Waste Glass

[0028] The physical separation system of metal impurities in the crushed waste glass is a primary crushing device & screening device, a primary magnetic separation device, a primary eddy current separation device, a secondary eddy current separation device, a screening device, a secondary Crushing device & screening device, three-stage crushing device & screening device, two-stage magnetic separation device, three-stage eddy current separation device, one-stage high-voltage electrostatic separation device and two-stage high-voltage electrostatic separation device, each The devices are connected by a material conveying device;

[0029] The method for separating metal impurities in waste glass by the system comprises the following steps:

[0030] S1. Coarsely crush and sieve the waste glass material in the primary crushing device & screening device to obtain waste glass material with a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com