Multifunctional winding device for PE wrapping film production

A winding device and multi-functional technology, which is applied in the field of multi-functional winding devices for PE stretch film production, can solve the problems of affecting PE stretch film, not being able to prevent pollution, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

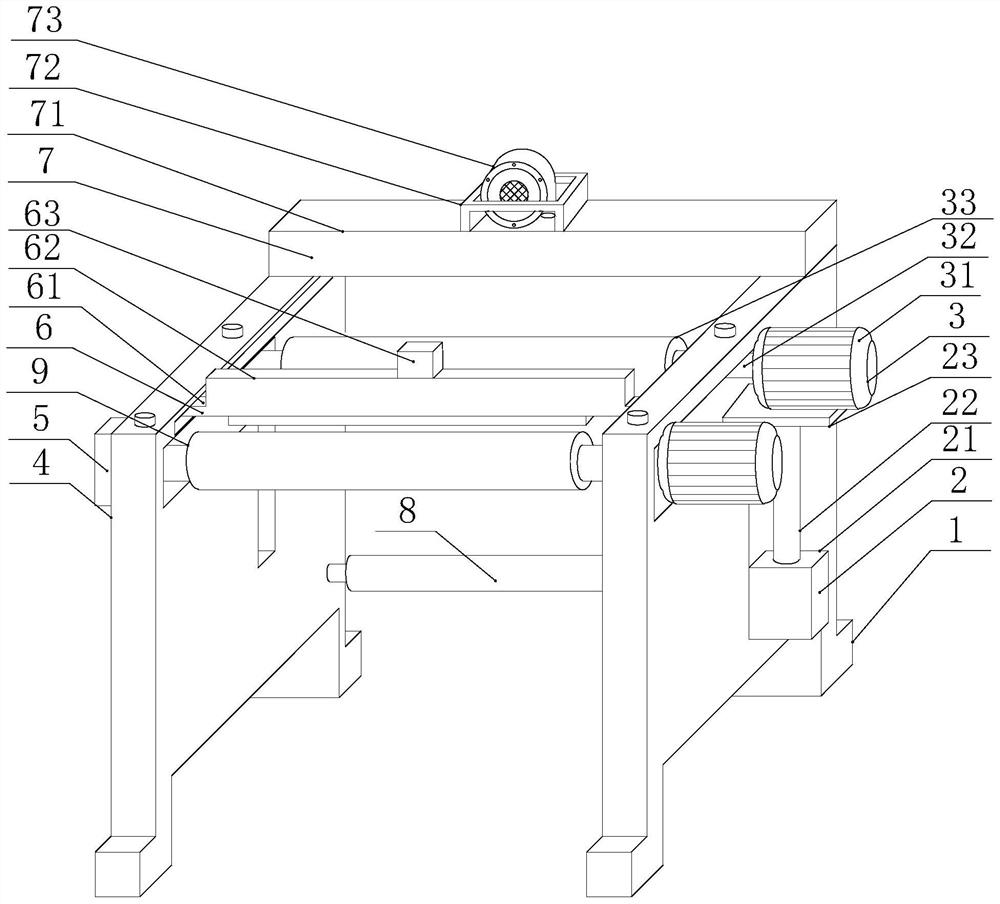

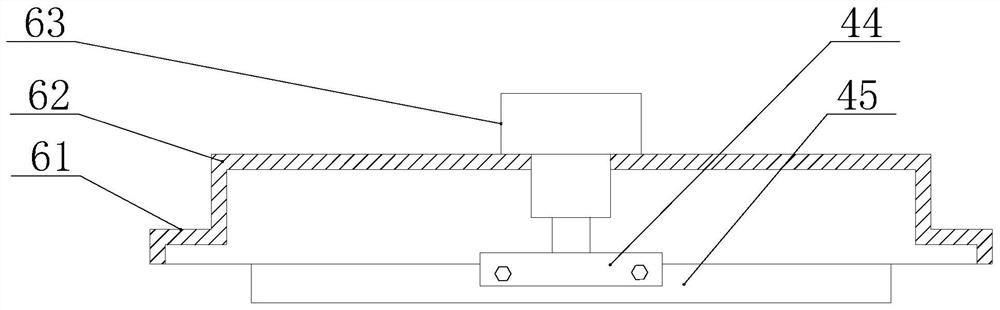

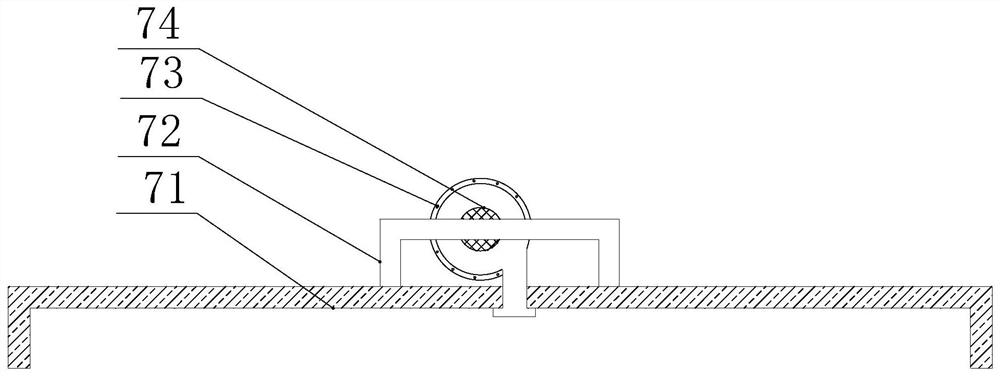

[0028] Example: such as Figure 1-6 As shown, a multifunctional winding device for PE stretch film production according to the present invention includes a first support base 1, and one end of the first support base 1 is provided with a pushing mechanism 2, and the winding motor of the winding mechanism 3 is pushed by the pushing mechanism 2 31 moves, the top of the pushing mechanism 2 is provided with a winding mechanism 3, and the winding mechanism 3 helps to rewind the PE stretch film. A conveying mechanism 5 is provided near the top end, and the conveying mechanism 5 helps to drive the first winding roller 34 to move, and a cutting mechanism 6 is provided at the top end of the first support seat 1 and the second support seat 4, and the cutting mechanism 6 is used to help cut off the PE winding The other end of the top of the first support base 1 and the second support base 4 is provided with a dust removal mechanism 7 to prevent dust from entering the top of the PE film an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com