Special tool for internal expansion type hoisting of motor stator core and working method of special tool

A technology for motor stators and special tools, applied in the direction of load suspension components, transportation and packaging, safety devices, etc., can solve the problems of difficult handling of motor stator cores, achieve good working stability and safety, simple structure, and compatibility and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

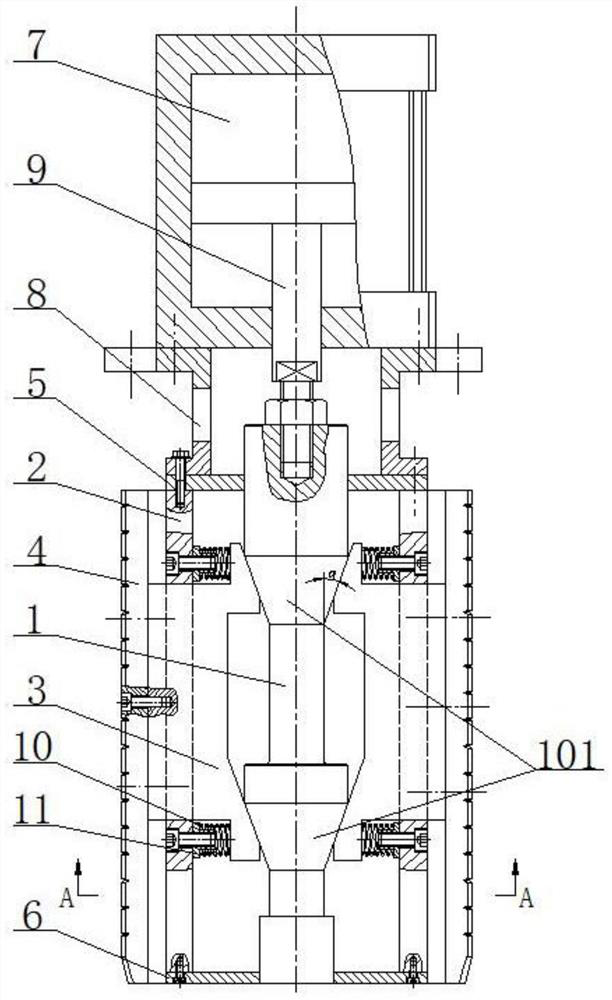

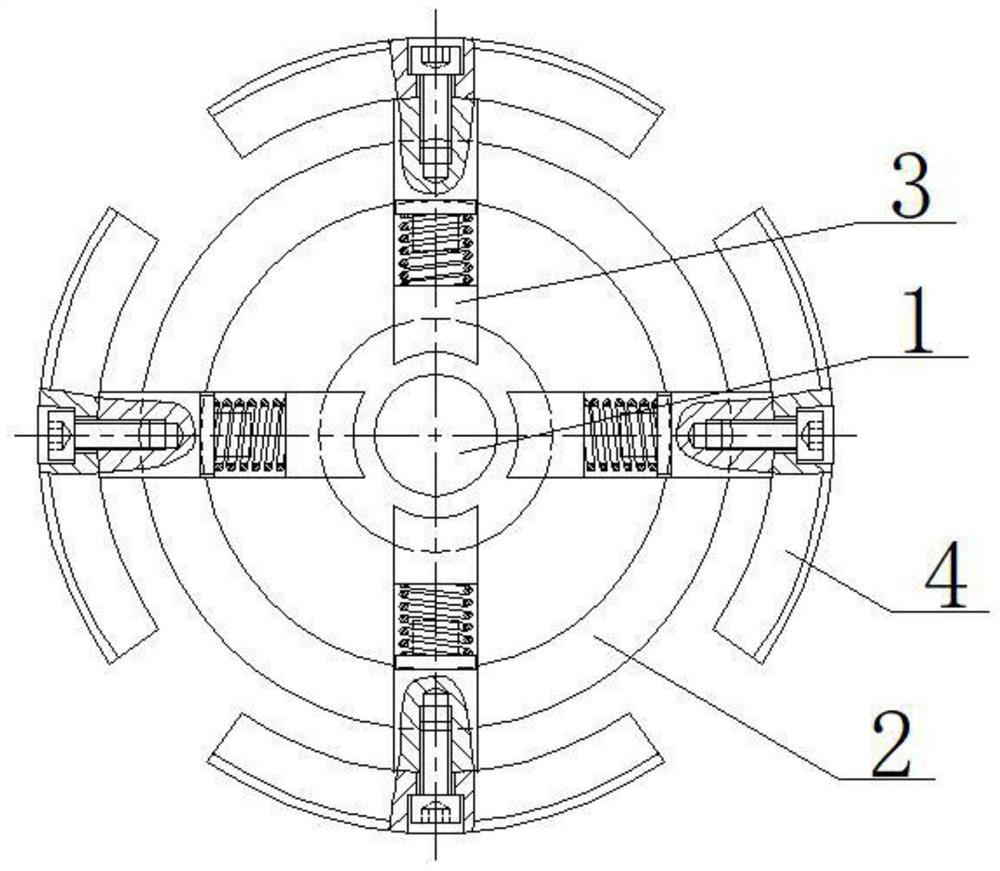

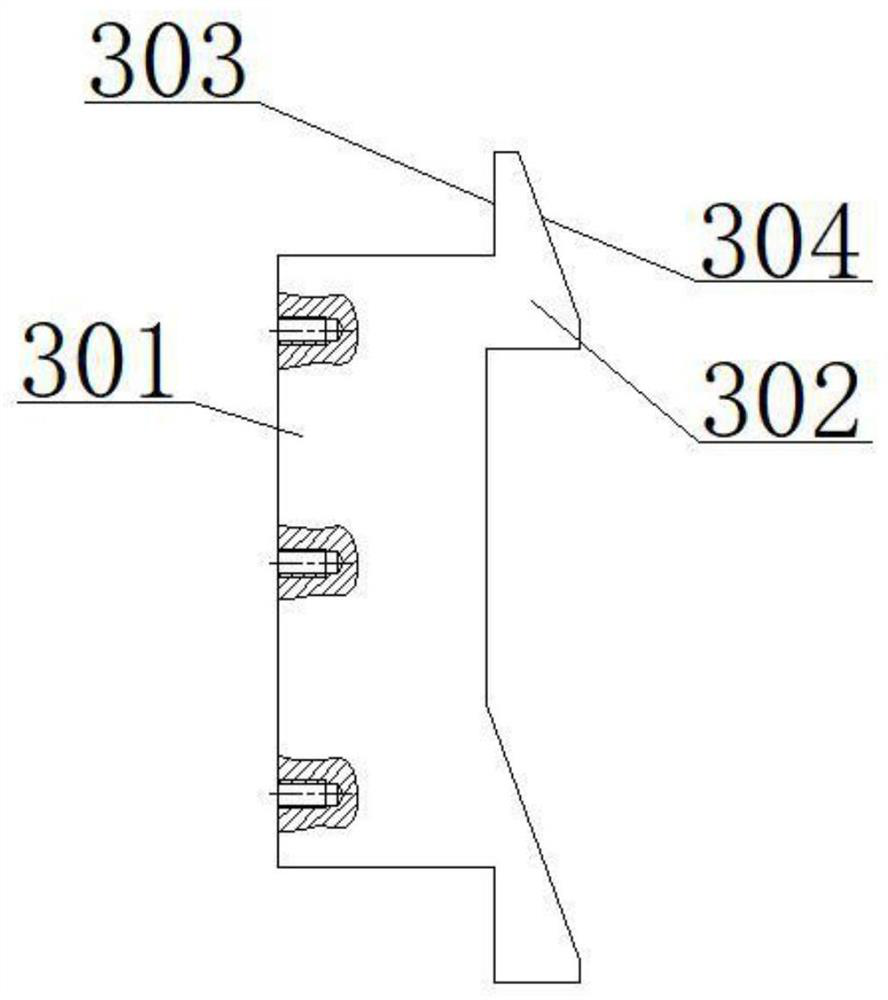

[0041] Such as Figure 1-Figure 4 As shown, the present invention provides a special lifting tool for motor stator core internal expansion, including a mandrel 1, a cylinder 2, a ram 3, an expansion plate 4, a ram reset device and a mandrel driving device, the mandrel The lower section of 1 is located in the cylinder 2, the upper end of the cylinder 2 is fixedly connected with the upper end cover 5, and the mandrel 1 is slidably connected with the center hole of the upper end cover 5. The lower end of the cylinder 2 is fixedly connected with a lower end cover 6, the lower end of the mandrel 1 is slidably connected with the central hole of the lower end cover 6, and the upper section of the mandrel 1 protrudes above the cylinder 2 and drives with the mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com