Workshop crane beam mounting method

An installation method and workshop crane technology, applied in the directions of transportation and packaging, load hanging components, support structures, etc., can solve the problems that the truss manipulator cannot install the column, it is difficult to install, the size adjustment is low, and the installation accuracy of the workshop column is low. Accurate and stable installation, solve the effect of low precision and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

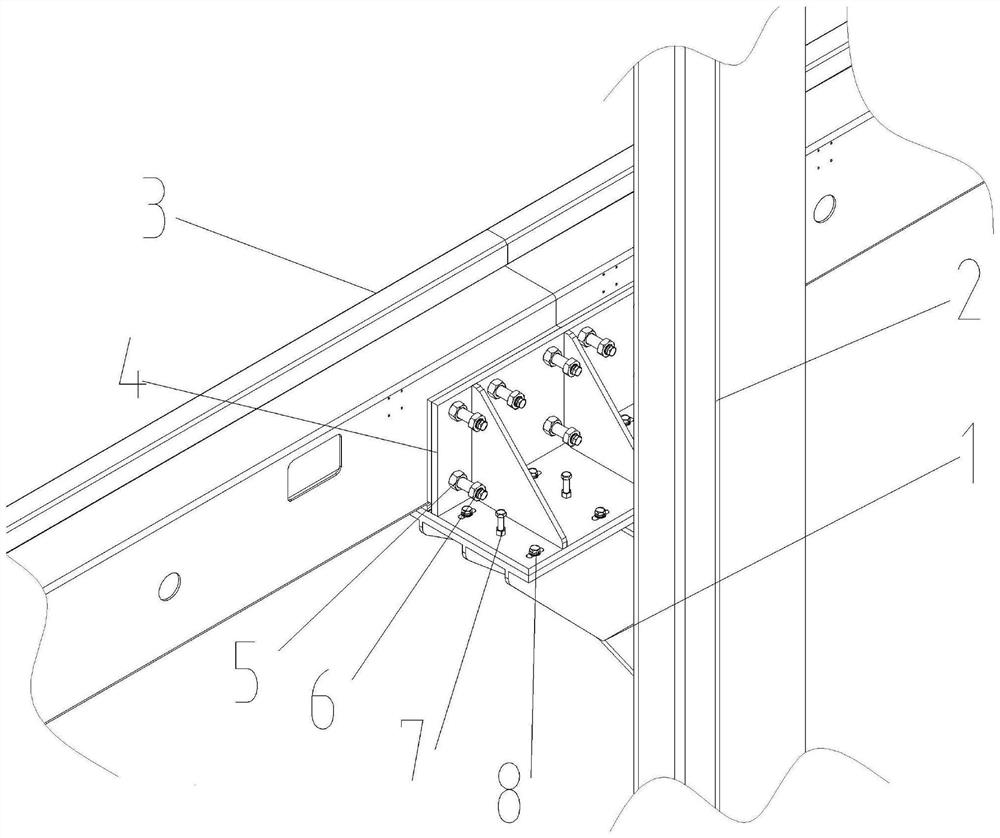

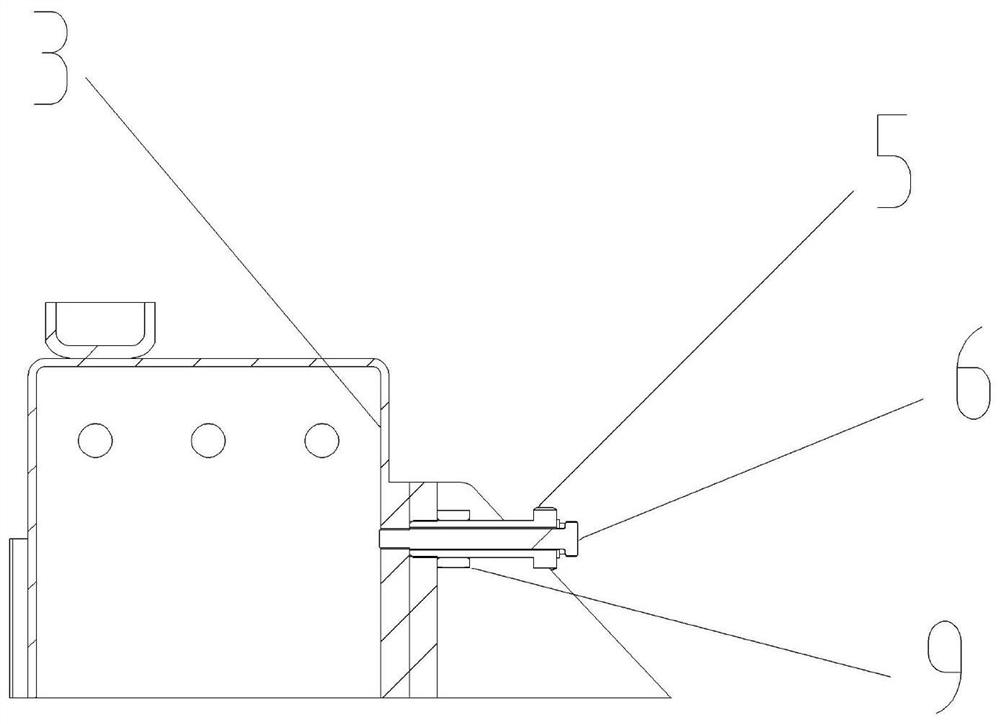

[0025] Such as Figure 1-2 As shown, a method for installing a crane beam in a workshop includes the following steps:

[0026] 1) Weld the corbel 1 to the side of the workshop column 2 according to the required flatness and straightness to ensure the welding strength.

[0027] 2) Fix the intermediate connecting plate 4 on the upper surface of the corbel 1, adjust the position of the left and right adjusting bolts 8 and the up and down leveling bolts 7, make the intermediate connecting plate 4 flush up and down, and the left and right spacing meet the design requirements, and fix it firmly.

[0028] 3) Lift the steel beam 3 to the installation height of the column 2 in the workshop.

[0029] 4) Install the steel beam 3 on the intermediate connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com