Soil nailing wall supporting structure

A technology of supporting structures and soil nailing walls, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as low construction efficiency and troublesome installation, and achieve the effects of improving construction efficiency, facilitating support, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

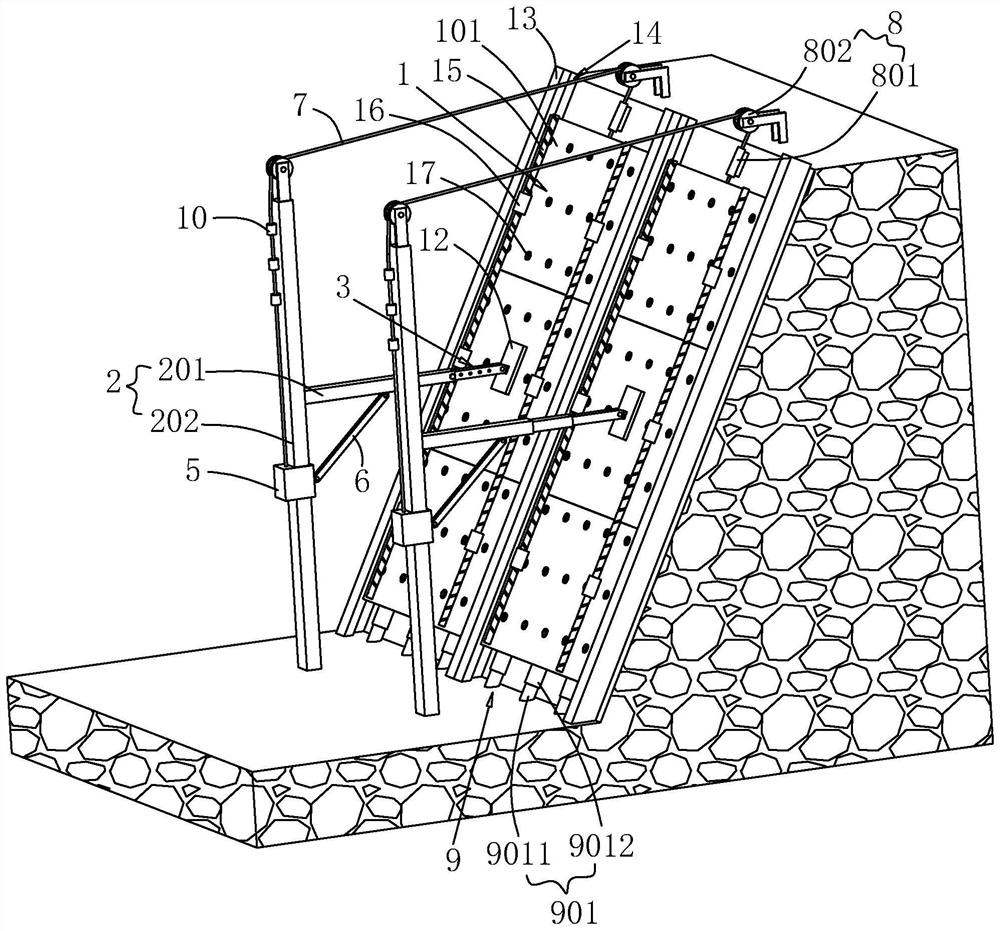

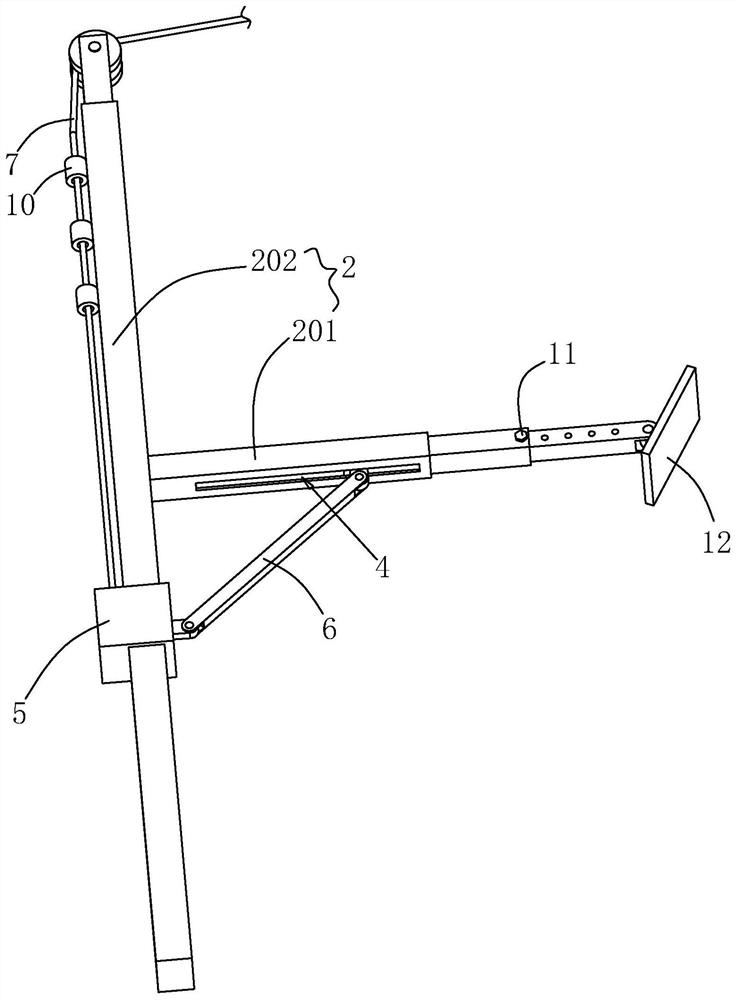

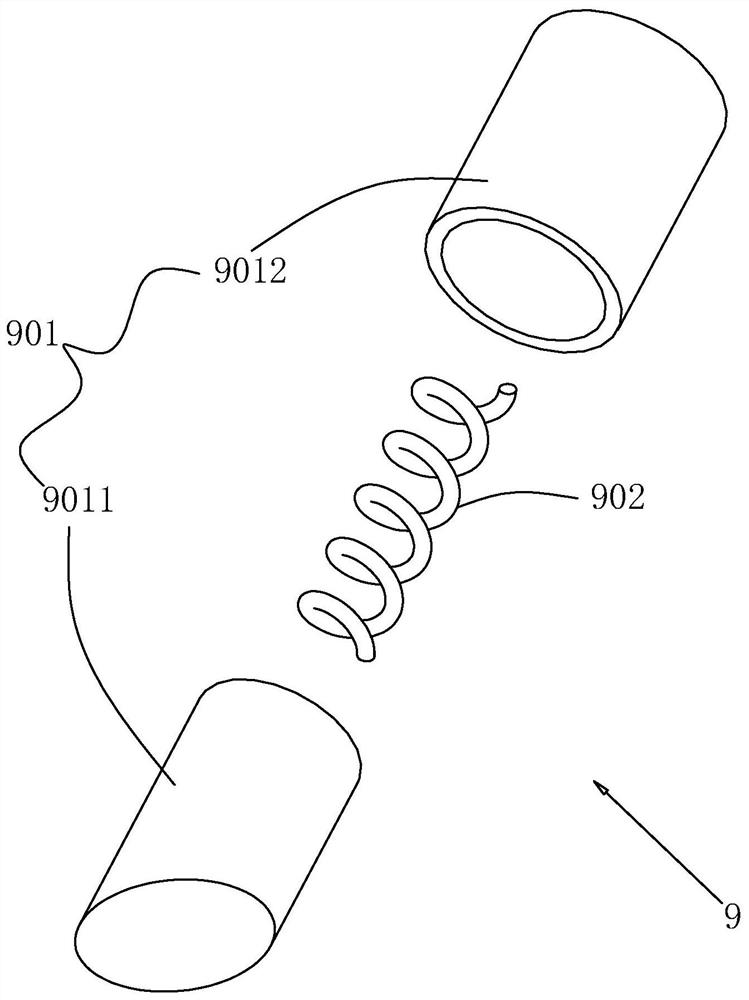

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses a soil nailing wall support structure. refer to figure 1, a soil nail wall support structure includes abutment and a supporting device 2 for abutting against the abutment plate 1 . The abutment plate 1 is provided with multiple pieces according to the length of the slope slope of the foundation pit. Each abutment plate 1 is spliced by several abutment plates 101. The abutment plate 101 is made of stainless steel. Each abutment plate 101 is welded with The ring 16 is provided with an internal thread. When the abutment plates 101 are spliced to form the abutment plate 1, two adjacent abutment plates 101 pass through the ring 16 through the screw 15 and are threadedly connected with the ring 16. Thus, the plurality of abutment plates 101 connected by the screw rods 15 are spliced to form the abutment plate 1 . The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com