Assembly type wall unit connecting plate body structure

A technology of wall units and connecting plates, applied to walls, building components, building structures, etc., can solve the problems of cumbersome methods, lack of modular working methods, increased labor costs and time costs, and achieve a high degree of integration , The effect of fast installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

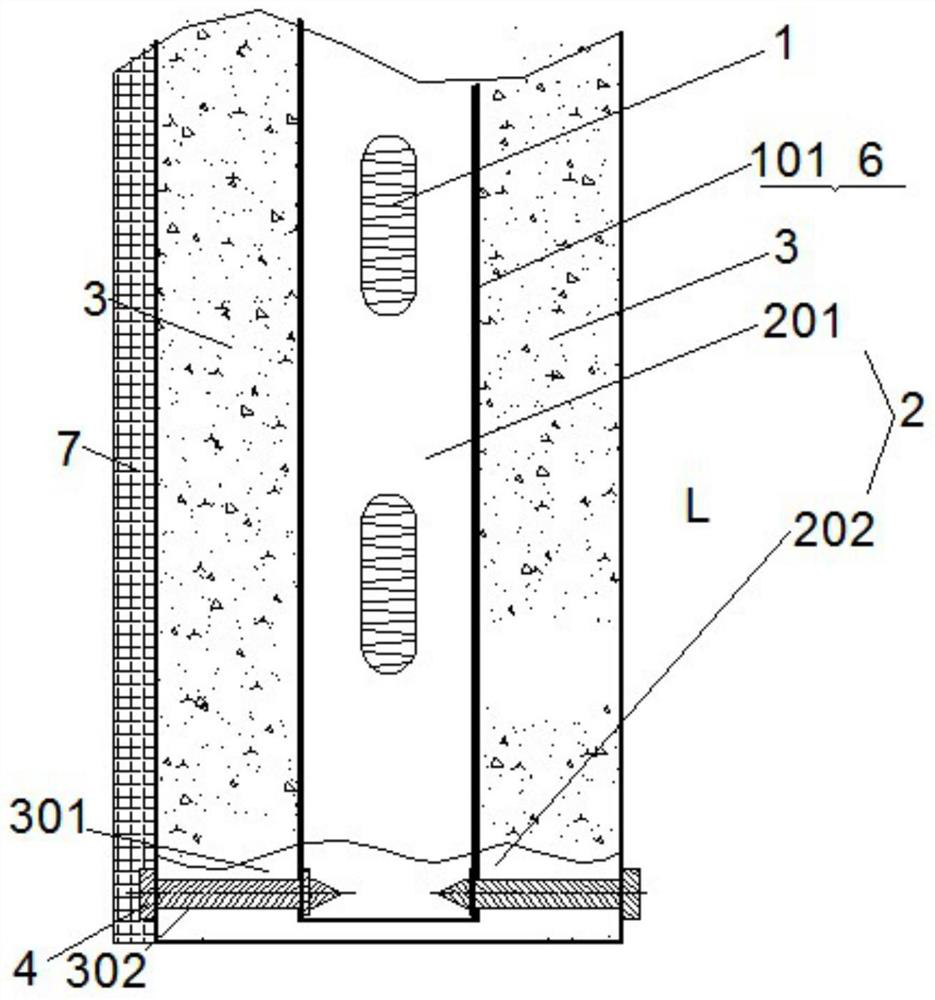

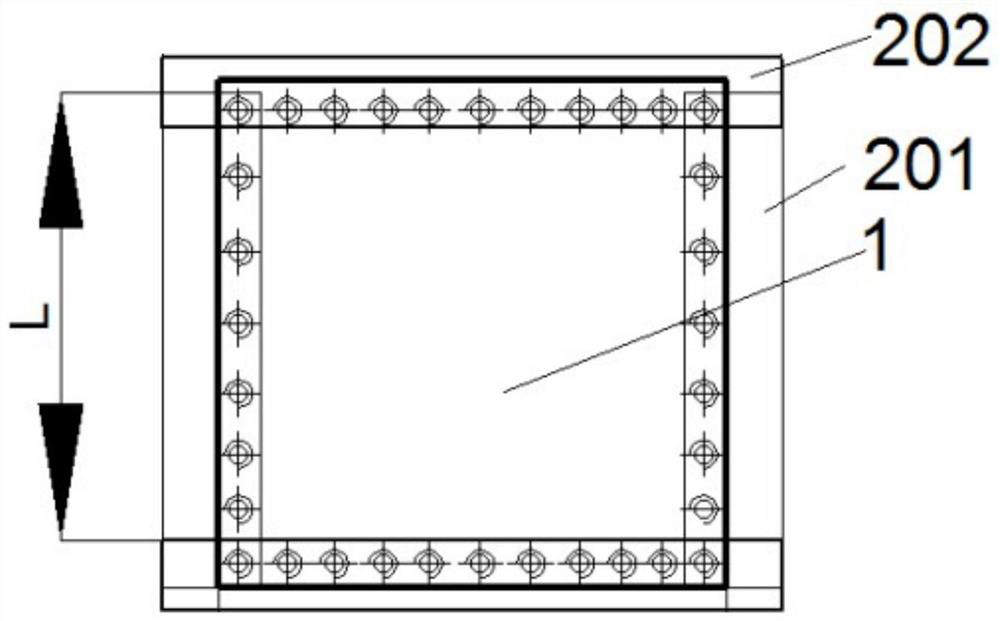

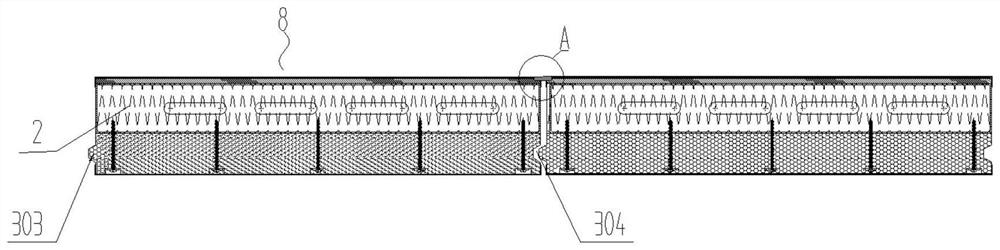

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 , image 3 , Figure 4 As shown, a prefabricated wall unit connection plate structure, the wall unit connection plate 8 includes rock wool 1, the rock wool 1 is rectangular, and the four side walls of the rock wool 1 are provided with lining boards 2, The liner 2 is concave, and the depression of the liner 2 is inserted on the side wall of the rock wool 1; ceramic foam bricks are arranged on one side of the rock wool contact plane 101, and a cement pressure plate is arranged on the other side 5. The aluminum veneer 7 is covered and connected to the cement pressure plate 5. The ceramic foam brick 3 is provided with a through hole 302, and the lining plate is provided with a threaded through hole 202A corresponding to the through hole 302 of the ceramic foam brick. The fixing bolt 4 passes through the through hole 302 and is screwed to the threaded th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com