Pumping well fixed liquid level pumping servo device using electric parameter curve analysis technology

A curve analysis, pumping well technology, applied in wellbore/well components, production fluids, earthmoving and other directions, can solve the problems of low work efficiency, high labor intensity of workers, long interval between collection cycles, etc., to achieve accurate determination. The effect of liquid level control, good economic benefits, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

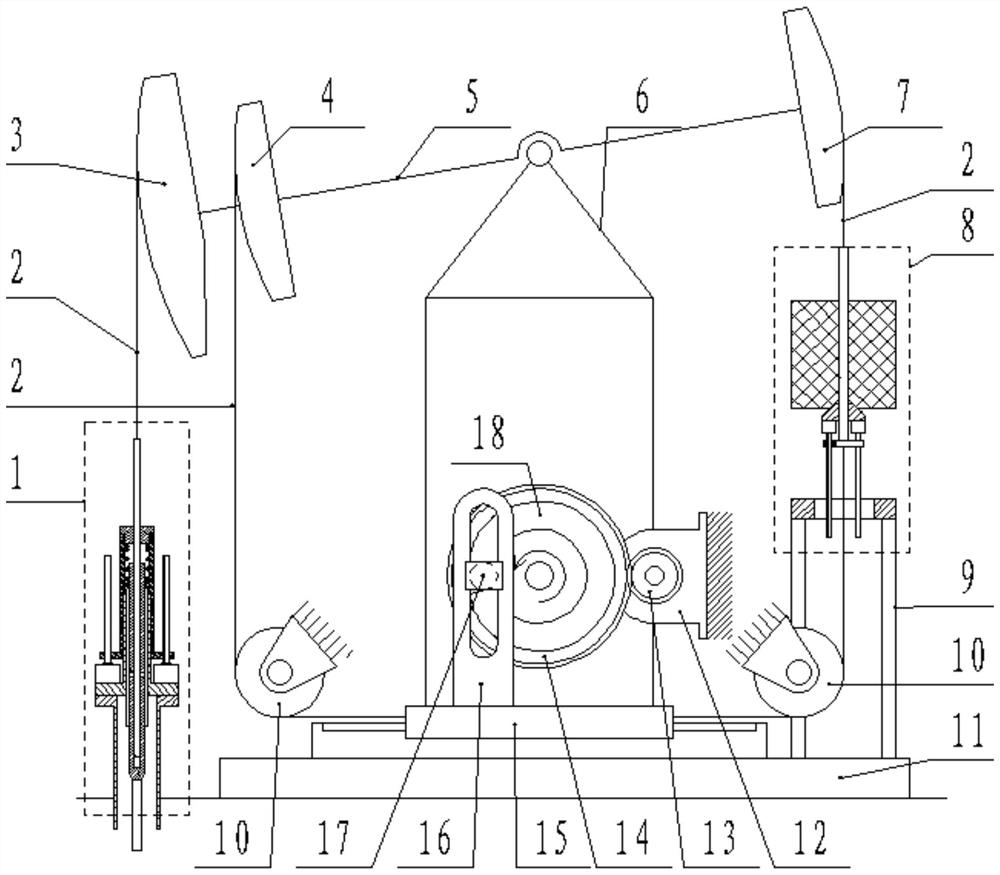

[0030] like figure 1 As shown, the present embodiment includes a pumping unit body and an electrical parameter acquisition device, wherein the pumping unit body refers to the mechanical body of the pumping unit, and the electrical parameter acquisition device refers to the voltage and current used for the servo motor 12 when working. , speed, and torque are collected by electrical devices. In the prior art, the electrical parameter acquisition device represented by the frequency converter has been widely used in the electrical control system of the beam pumping unit, and will not be repeated here.

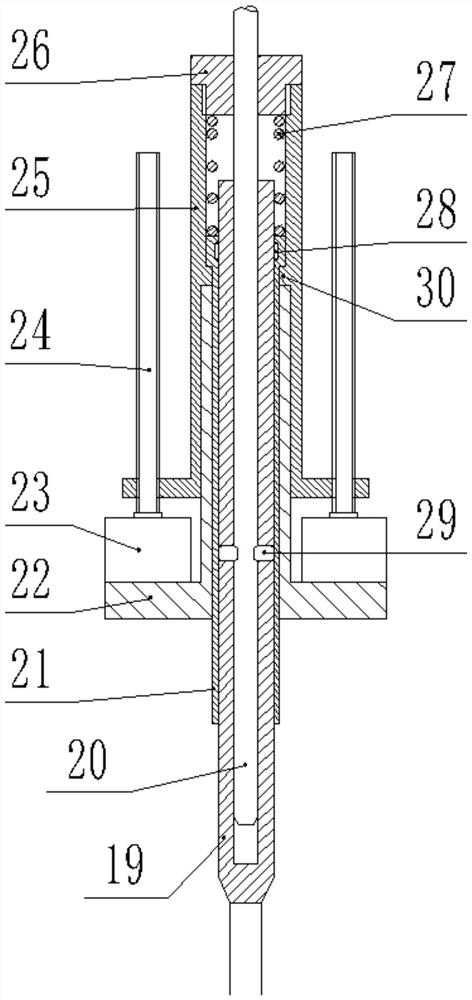

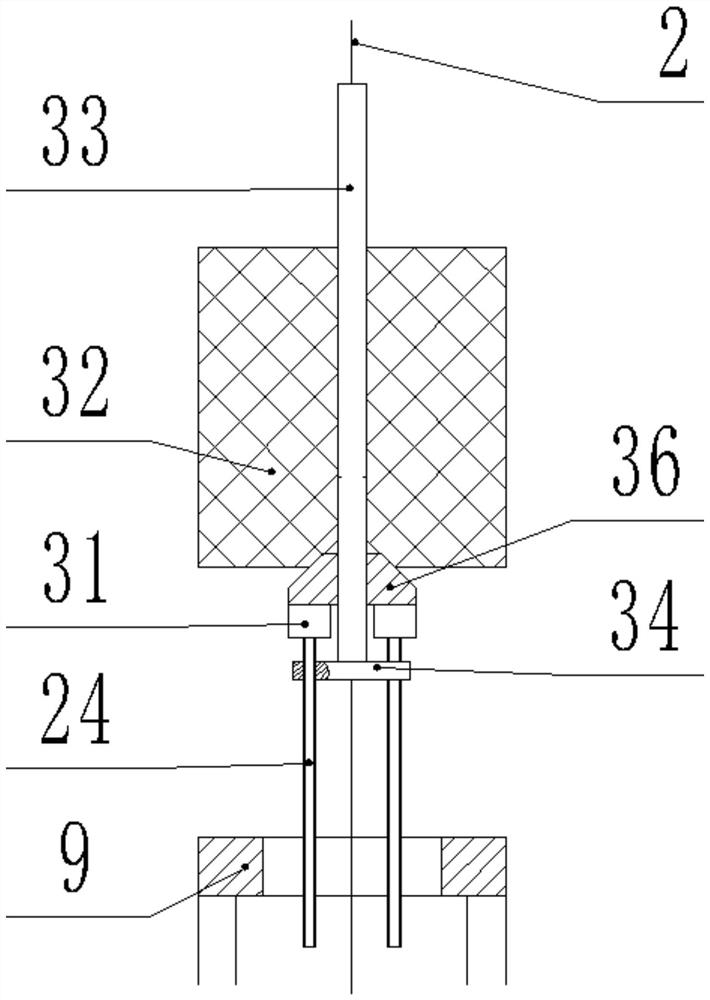

[0031] In the present invention, the pumping unit body includes a base 11, a beam 5, a bracket 6, a main donkey head 3, an auxiliary donkey head 4, a counterweight donkey head 7, a speed regulating motor 12, a flywheel 14, a slide seat, a slide plate 15, a Stroke assembly 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com