Bend-position shunting and mutual-weakening type self-protective petroleum pipeline

A technology for oil pipelines and bends, applied in pipeline protection, pipeline damage/wear prevention, elbows, etc., can solve problems such as oil pipeline crack damage, large pipeline damage, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

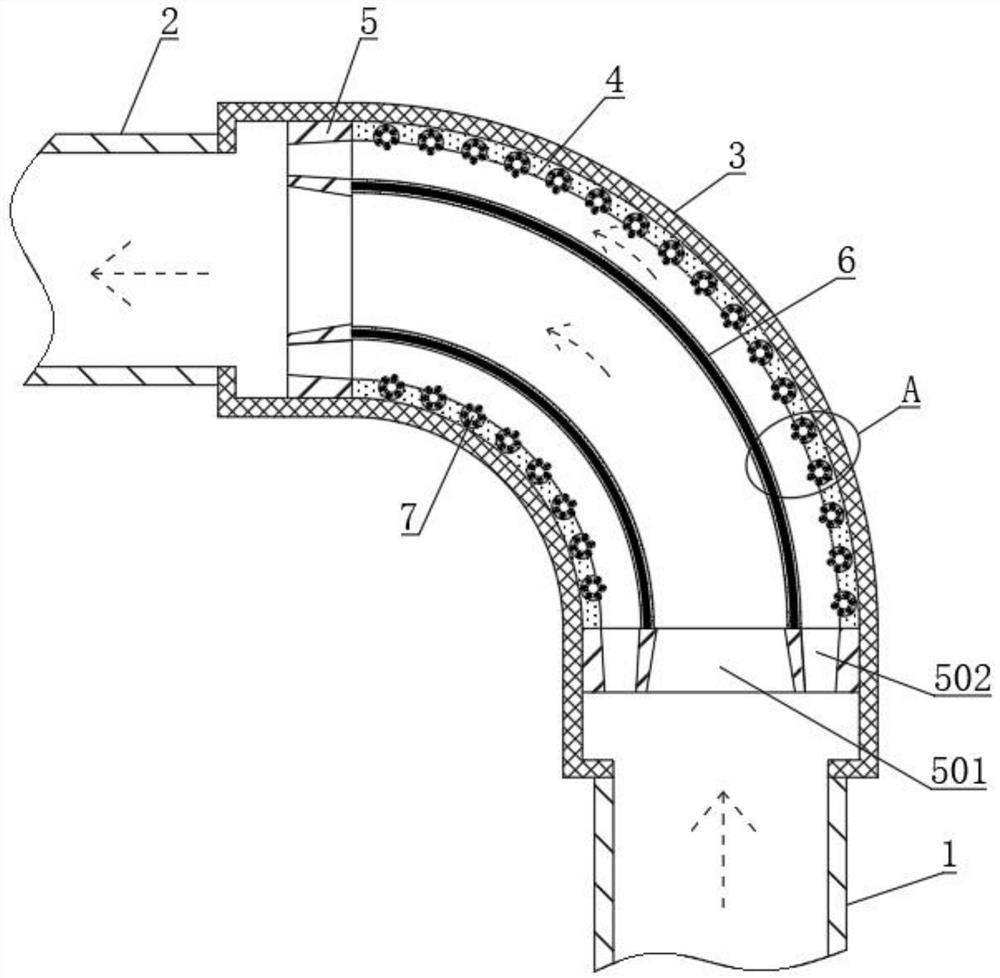

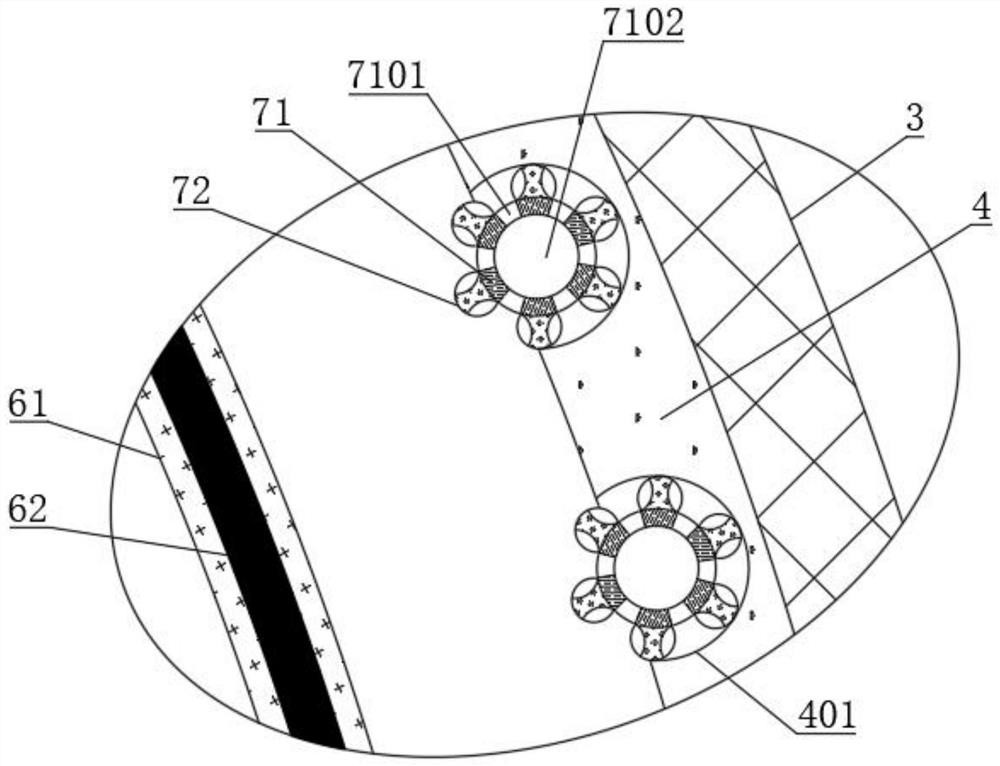

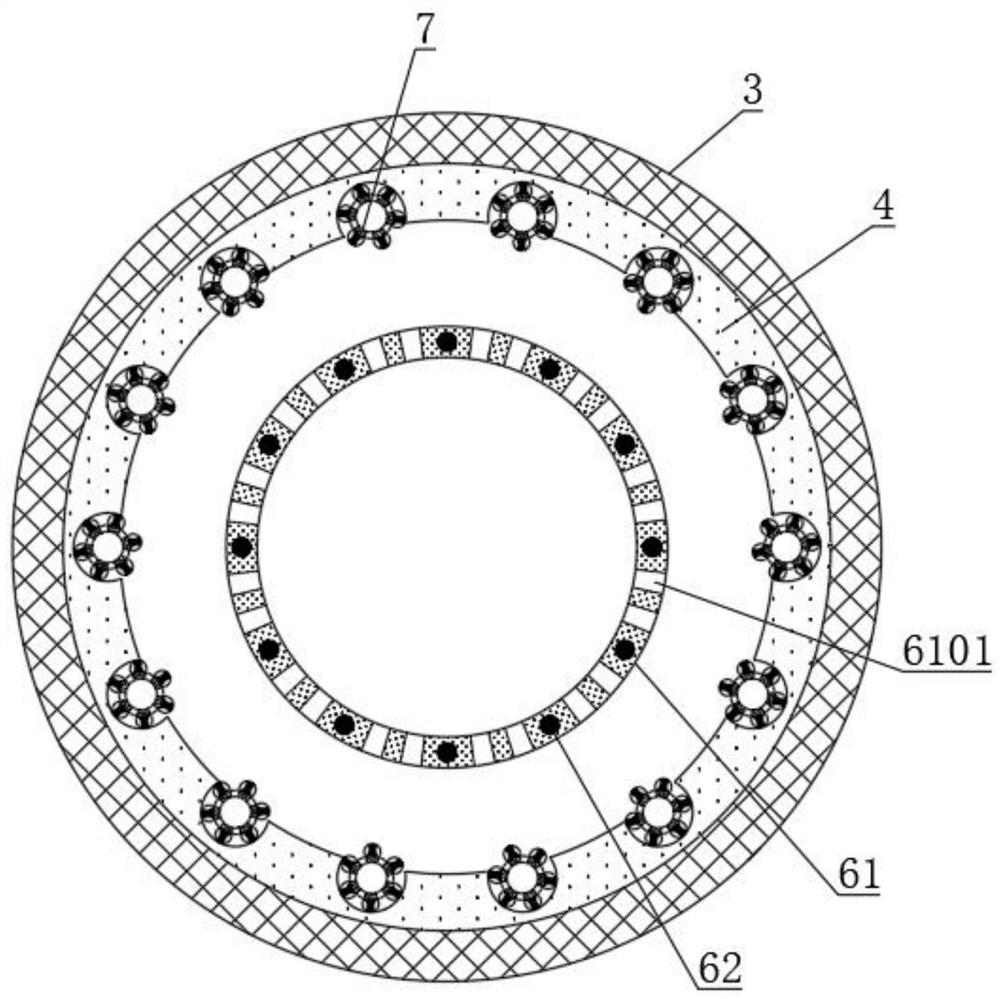

[0039] see figure 1 , a kind of self-protection oil pipeline with flow diversion and mutual elimination at the bend, comprising a plurality of pipeline joints connected in sequence, the pipeline joints include an oil inlet pipe 1, an oil outlet pipe 2 and a bent pipe, and the bent pipe is located between the oil inlet pipe 1 and the oil outlet pipe 2 Between, the bent tube includes an outer bent tube 3 fixedly connected between the oil inlet pipe 1 and the oil outlet pipe 2, the inner wall of the outer bent tube 3 is fixedly connected with an inner bent tube 4 and a pair of deflector plates 5, and the inner bent The folded tube 4 is fixedly connected between a pair of deflector plates 5, and the inner side of the bent tube 4 is provided with a diversion deformation sleeve 6, and the diversion deformation sleeve 6 is fixedly connected between a pair of deflector plates 5, and the deflector plate 5 There are an inner flow channel 501 and a plurality of outer flow channels 502, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com