Pedal simulator adjusting fork hole position detection device with automatic righting function

A pedal simulator and self-righting technology, which is applied in the field of inspection and inspection, can solve the problems that it is difficult to meet the stability requirements of the inspection system, the stability control requirements of the manufacturing process, the poor repeatability and reproducibility of the inspection results, and the large differences in the inspection results. Achieving fast detection and output results, avoiding differences in detection results, high repeatability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

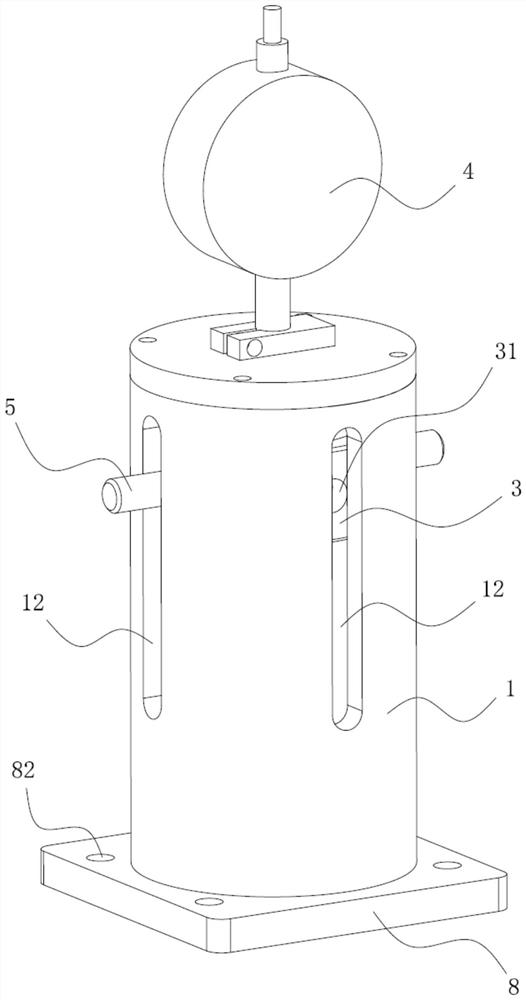

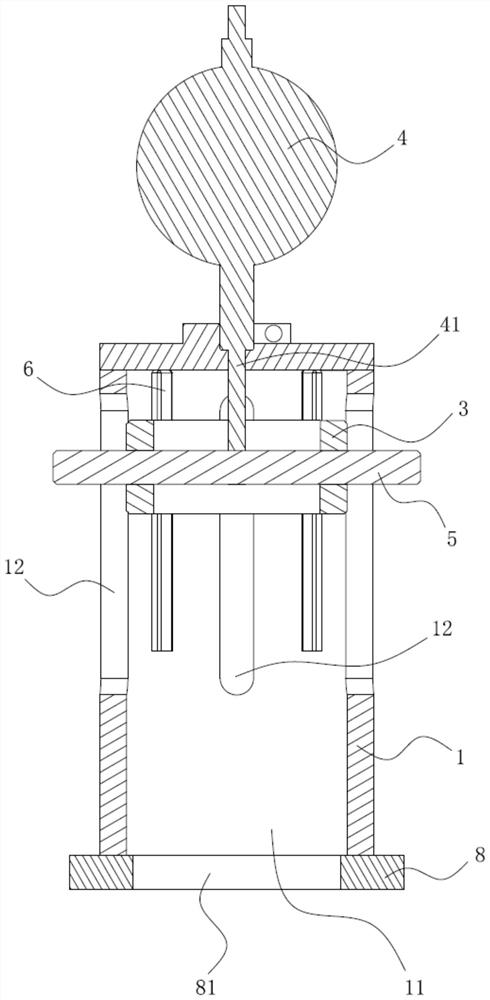

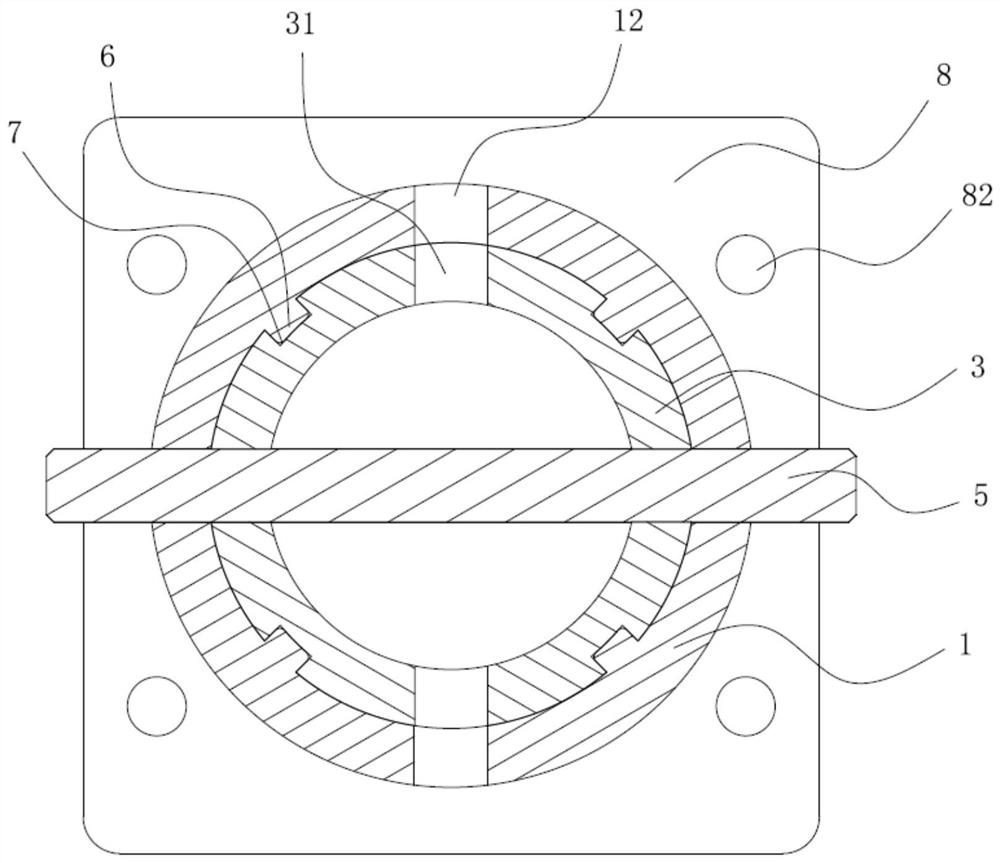

[0034] The embodiment discloses a pedal simulator adjustment fork hole position detection device with an automatic righting function and a pedal simulator adjustment fork hole position detection method based on the detection device. like Figure 1 to Figure 6 As shown, the detection device includes a hollow cylindrical casing 1, the bottom of the casing 1 is provided with a casing opening 11 for the entry and exit of the part 2 to be detected, and the side wall is provided with a measuring groove 12 extending axially along the casing 1. The measuring groove 12 Preferably it is a long hole. A guide slider 3 is arranged inside the casing 1 , and a measuring hole 31 is arranged on the side wall of the guide slider 3 . The guide slider 3 is configured to move along the axis of the casing 1 but not to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com