Test equipment and test method for tracking resistance and electrical erosion resistance

A technology of tracking resistance and test equipment, which is applied in the direction of measuring electricity, measuring electrical variables, and testing dielectric strength, etc., can solve the problem that the test results cannot be effectively evaluated, the flow rate of polluted liquid cannot be accurately controlled, and it is difficult to return to power failure To avoid problems such as the previous state, to avoid differences in test results, to occupy a small area, and to facilitate the installation of test products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

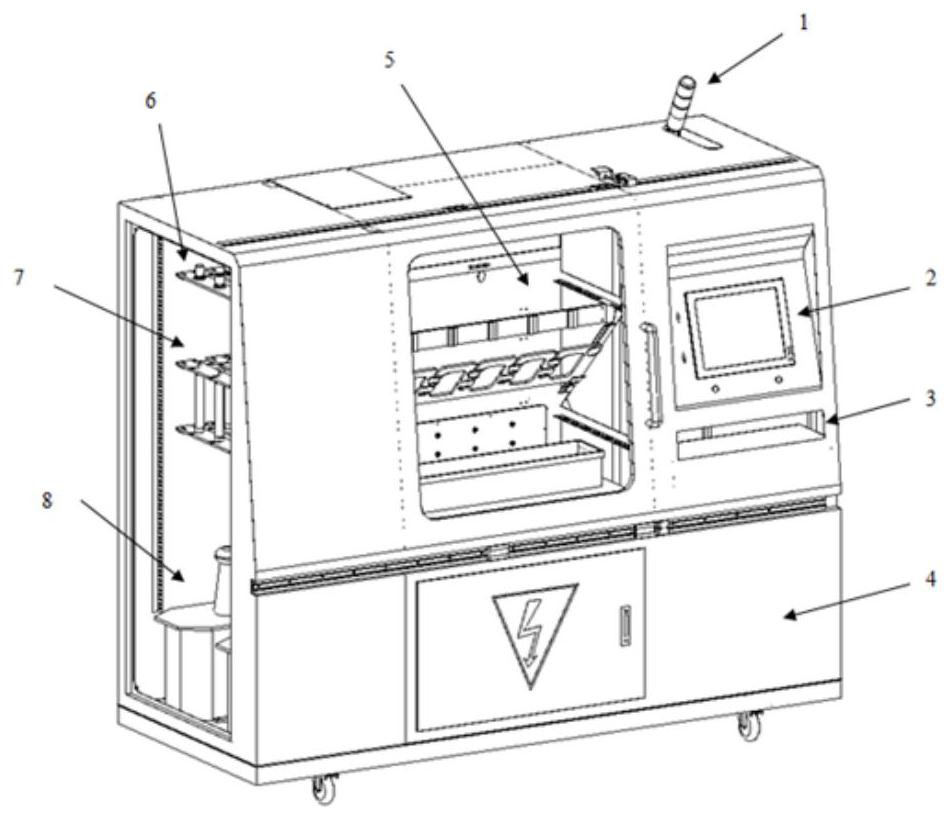

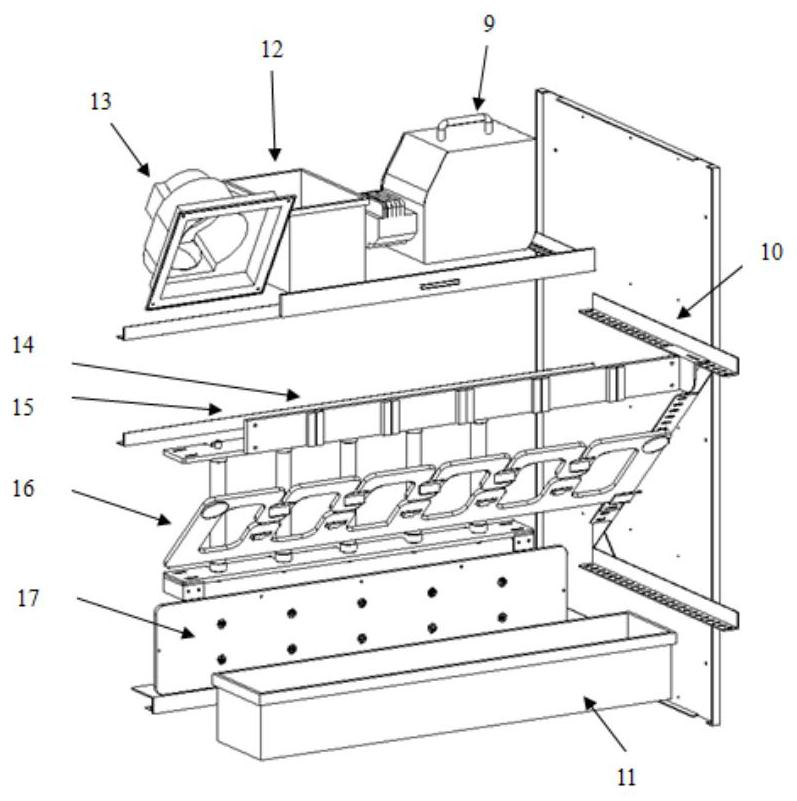

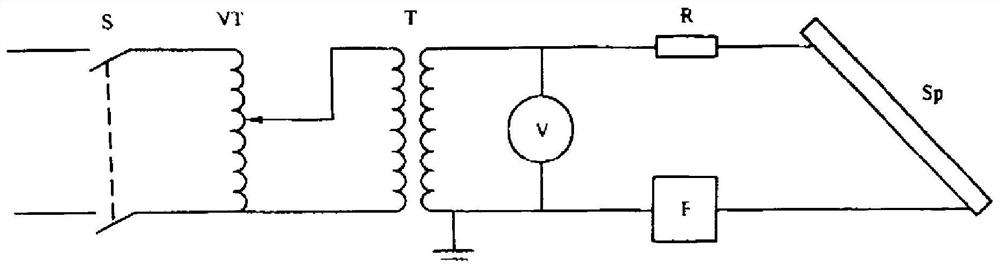

[0043]In order to better understand the technical solution of the present invention, the technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiments of the present invention. Embodiments are merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor should belong to the scope of the present invention.

[0044] It should be noted that when the element is referred to as "set to" another element, it can be directly in another element or can also exist another component. When an element is considered to be "connected" another element, it can be directly connected to another element or may always exist another component. The term "vertical", "horizontal", "horizontal", "left", "right", and similar expressions are merely illustrative, and the only embodiment is not shown.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com