Patents

Literature

35 results about "Step tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

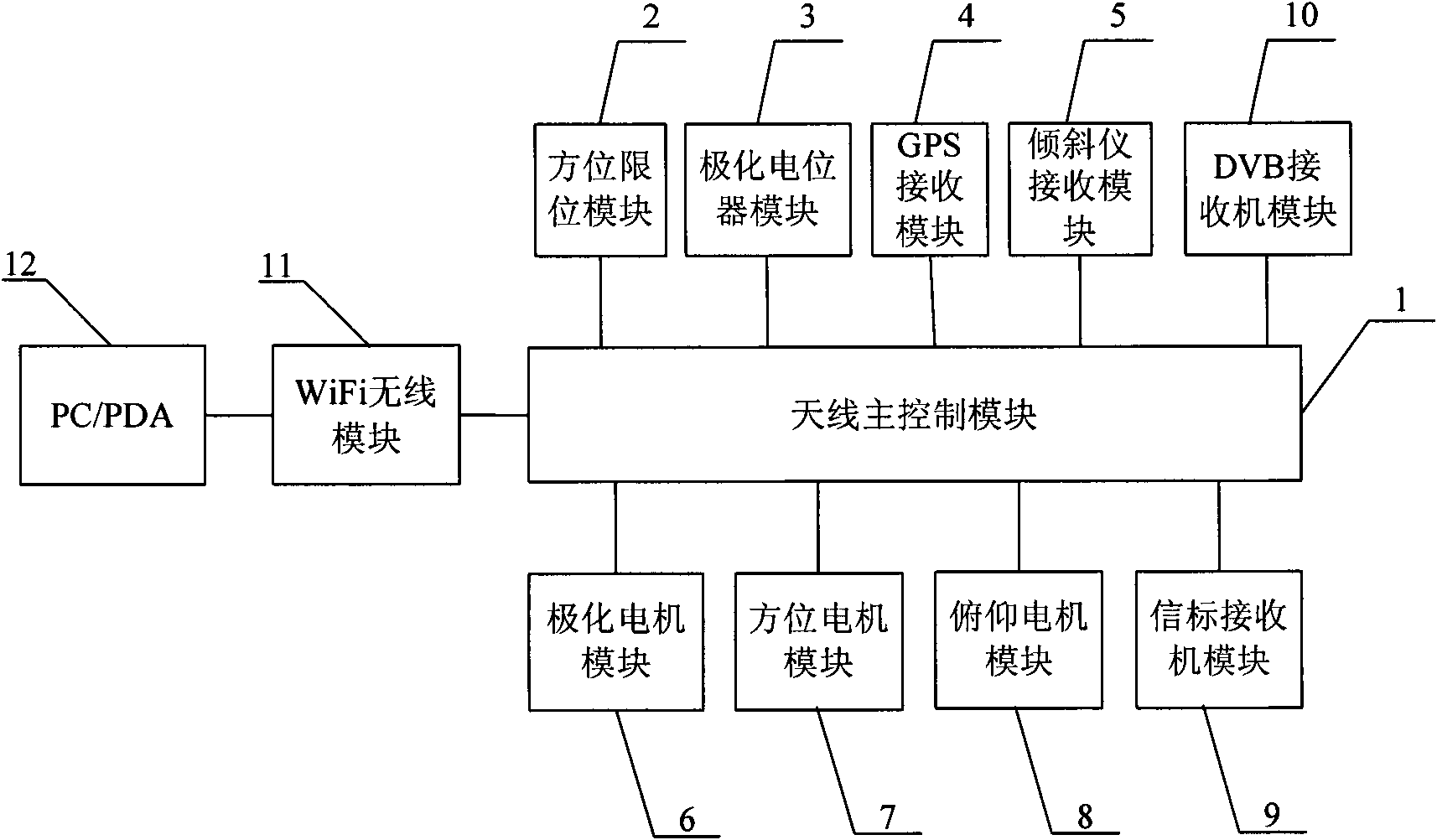

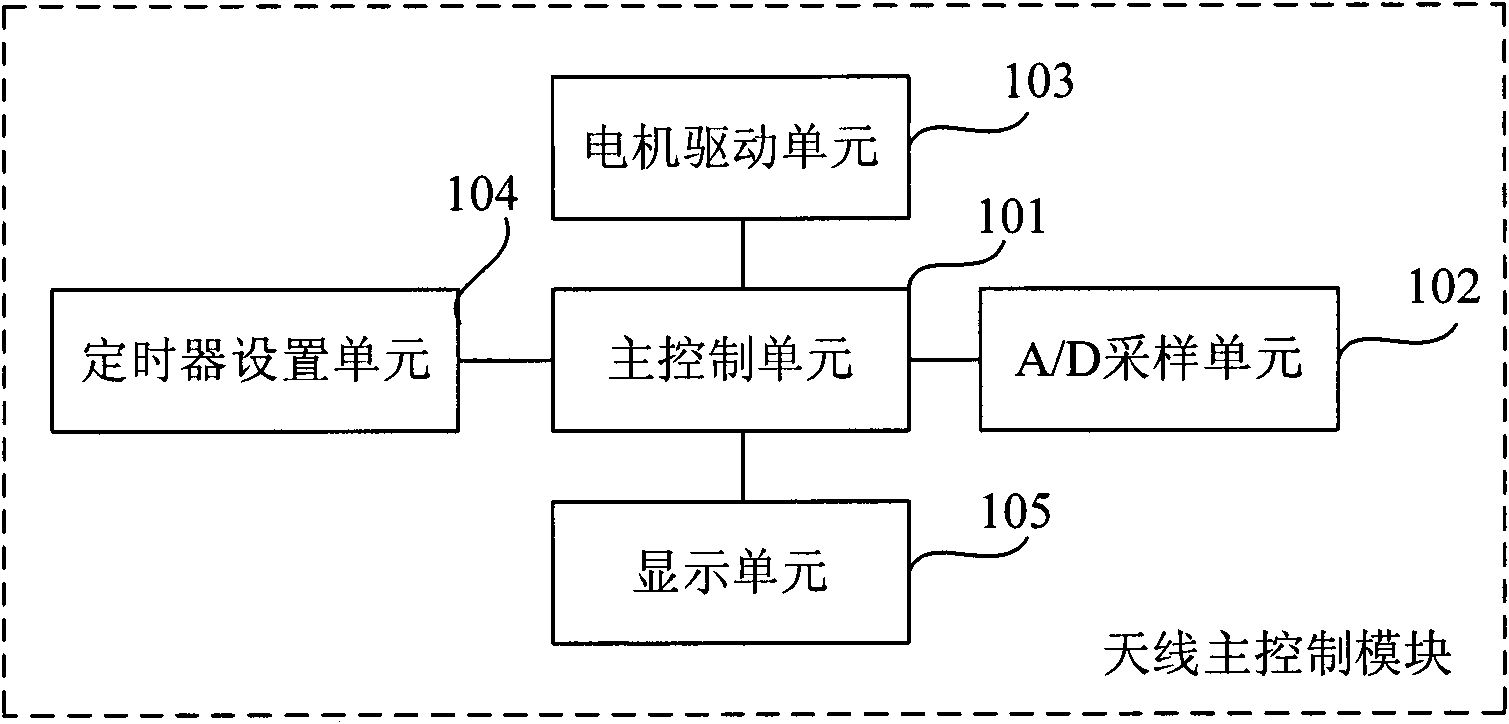

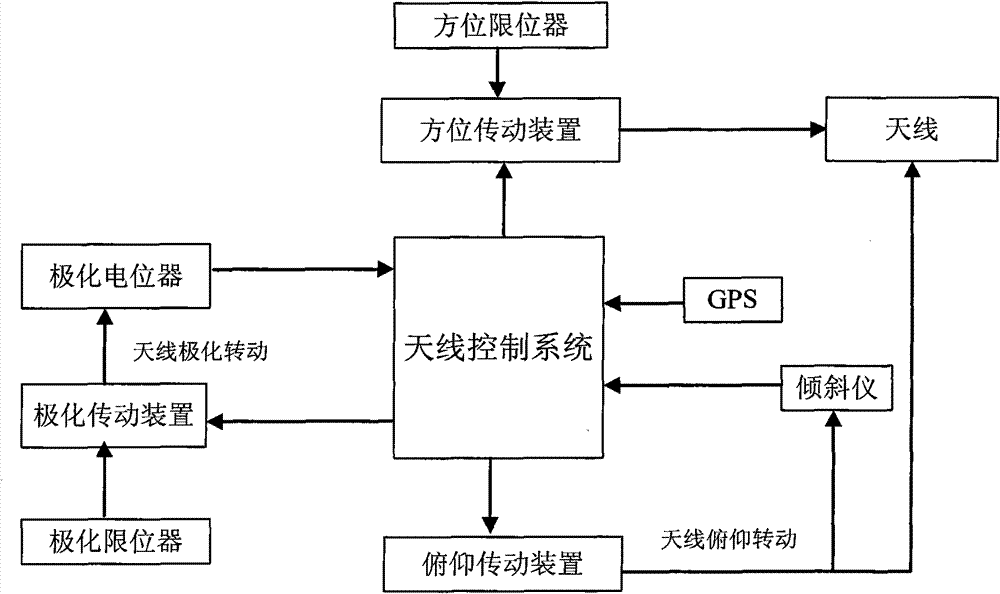

Intelligent control system for portable satellite antenna and method

ActiveCN101943913AAccelerate the star speedIntelligent operation and useAntennasPosition/direction controlComputer moduleEngineering

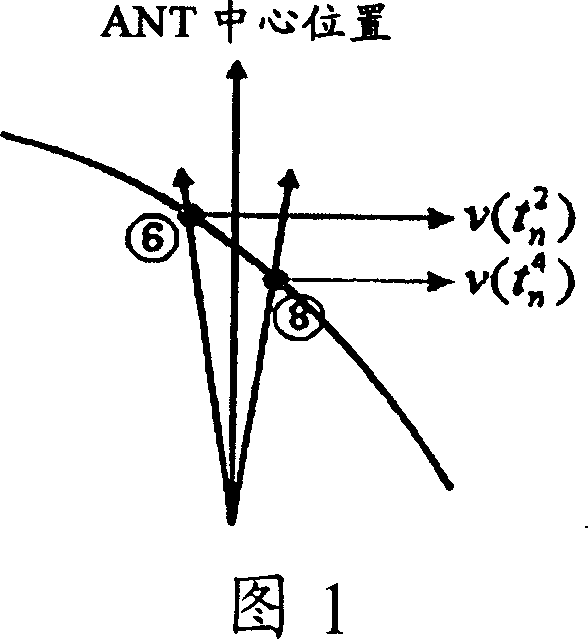

The invention discloses an intelligent control system for a portable satellite antenna and a method, wherein the method comprises the steps of initializing an antenna; controlling the antenna through an antenna main control module to search; reading satellite signal level data transmitted by a receiver module at a certain frequency; regulating the direction and the pitch angle of the antenna to the direction and the pitch angle corresponding to the maximum satellite signal level data; adopting a step tracking way to regulate the direction and the pitch angle of the antenna; controlling motors to carry out regulatiion by a step in the current direction by the antenna main control module if the regulated level data of the current time is larger than the level data obtained after the last regulation; and controlling the motors to carry out regulation by a step in the opposite direction by the antenna main control module until the antenna receives the maximum signal level if the regulated level data of the current time is less than the level data obtained after the last regulation. The invention can ensure that the efficiency and the accuracy of star pairing can be enhanced; the star pairing time is saved; and the star pairing operation is simplified.

Owner:AKD COMM TECH

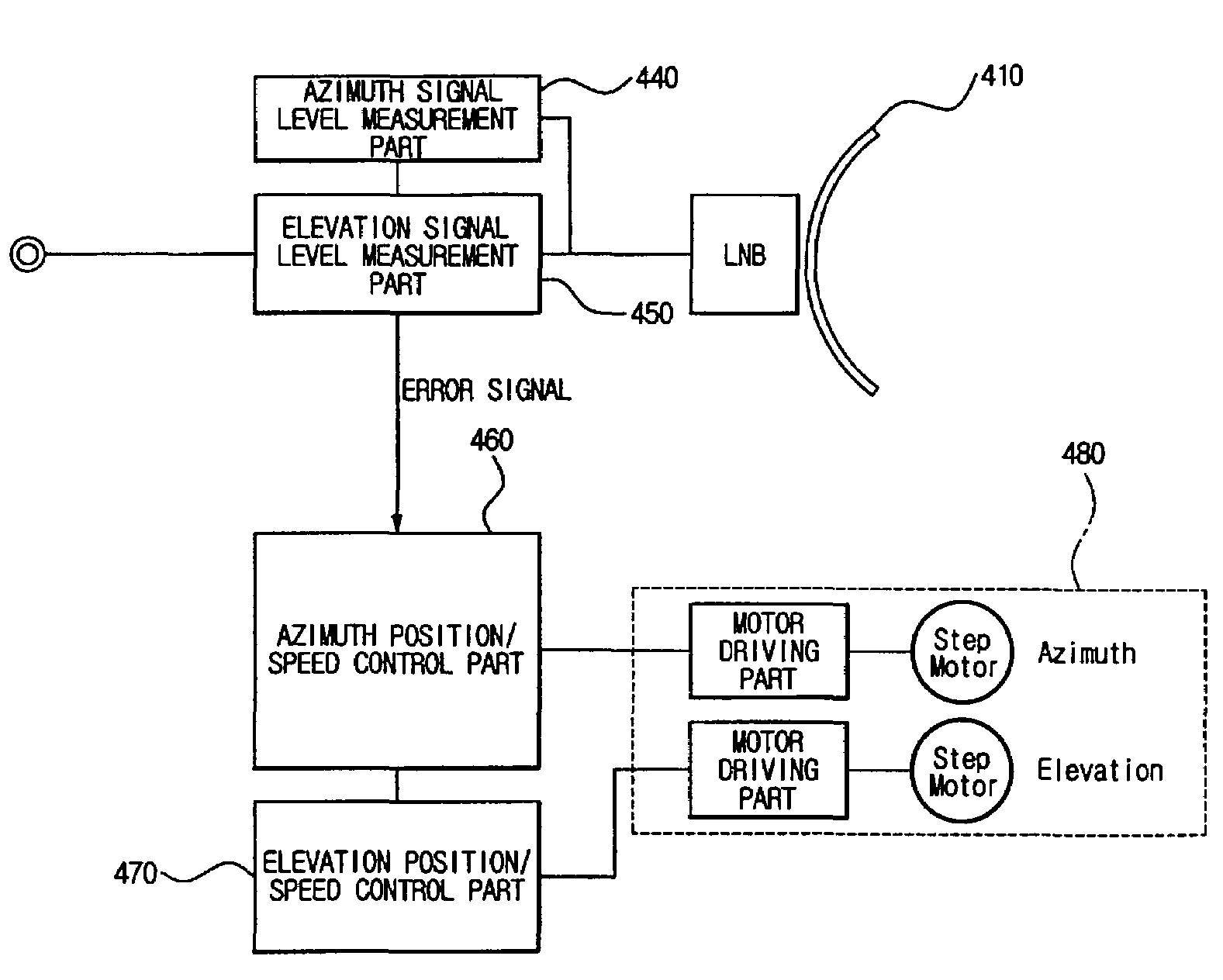

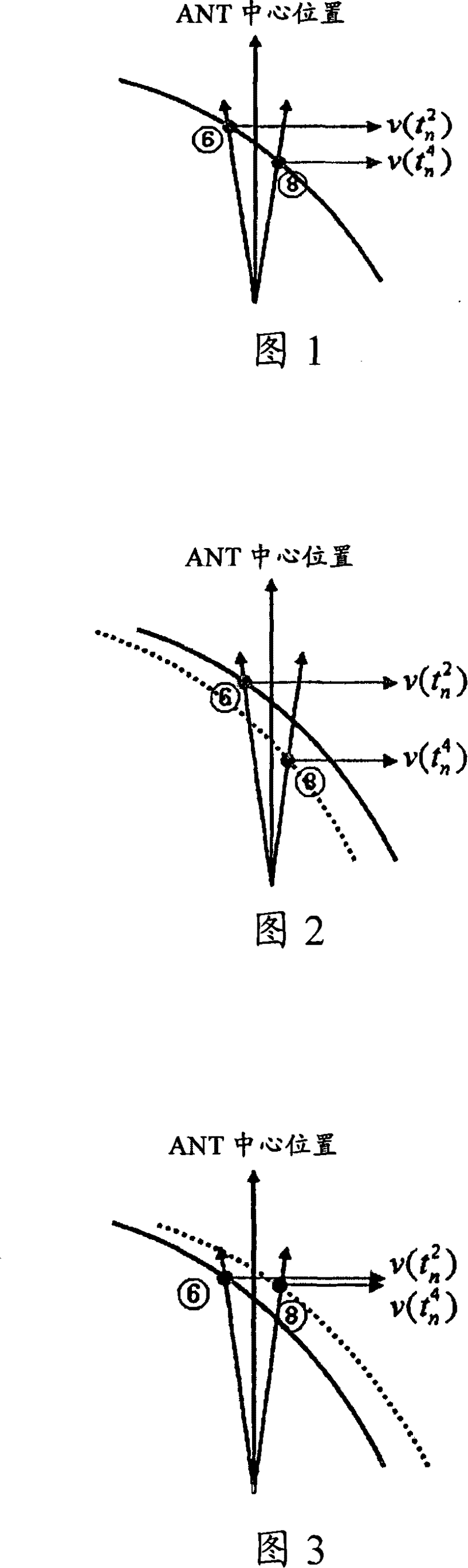

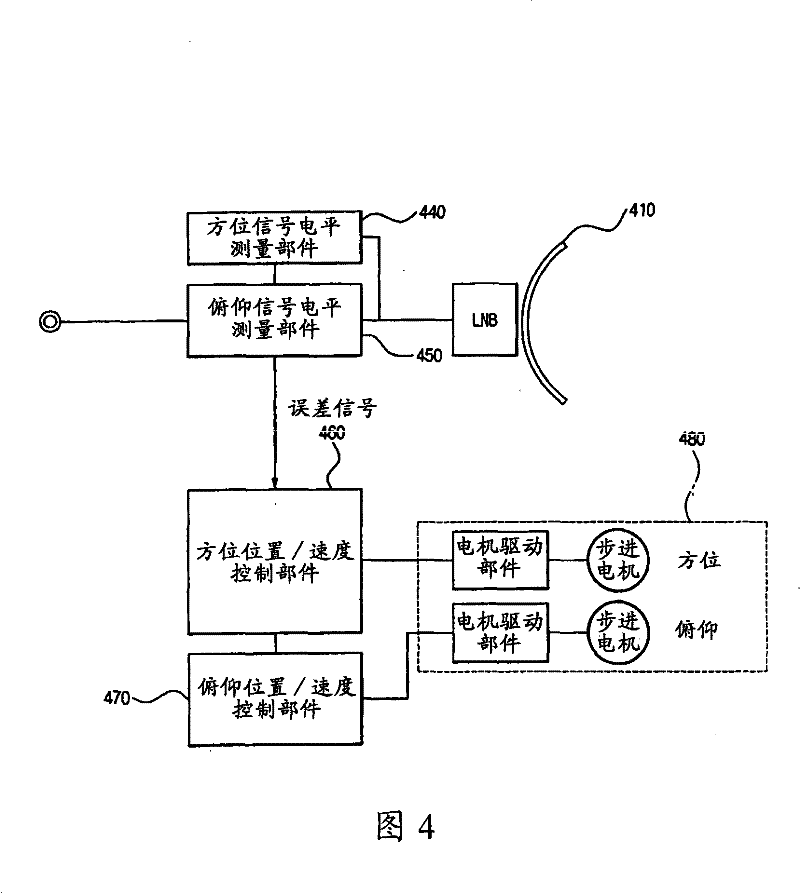

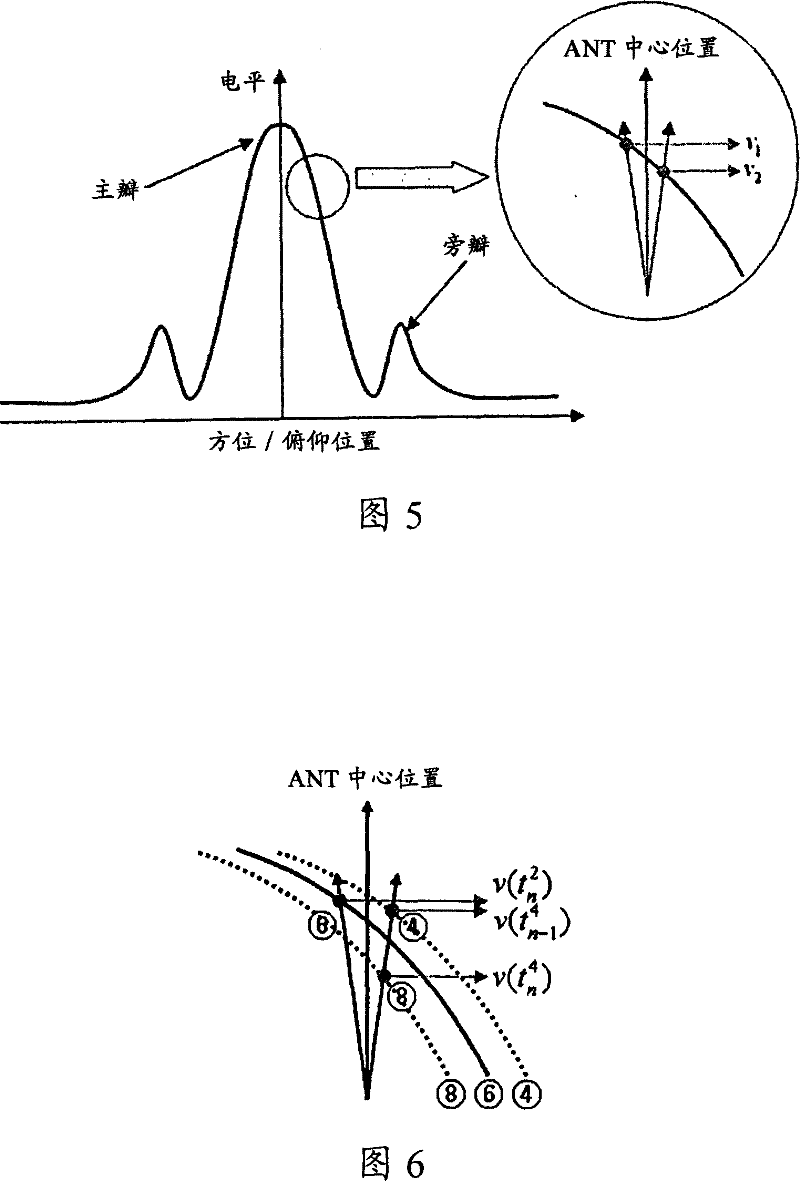

Satellite tracking antenna system and method therefor

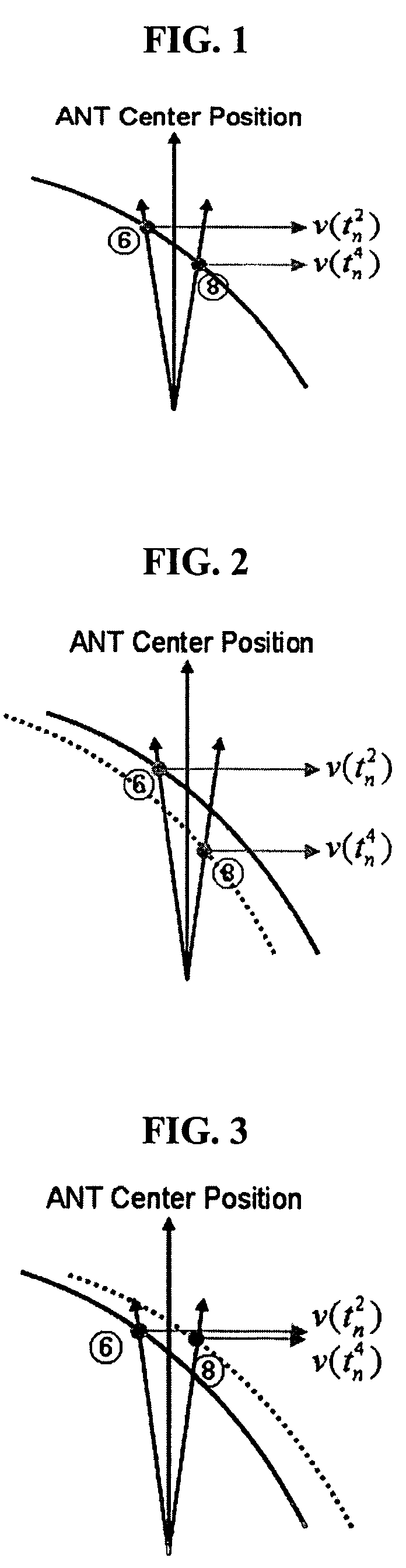

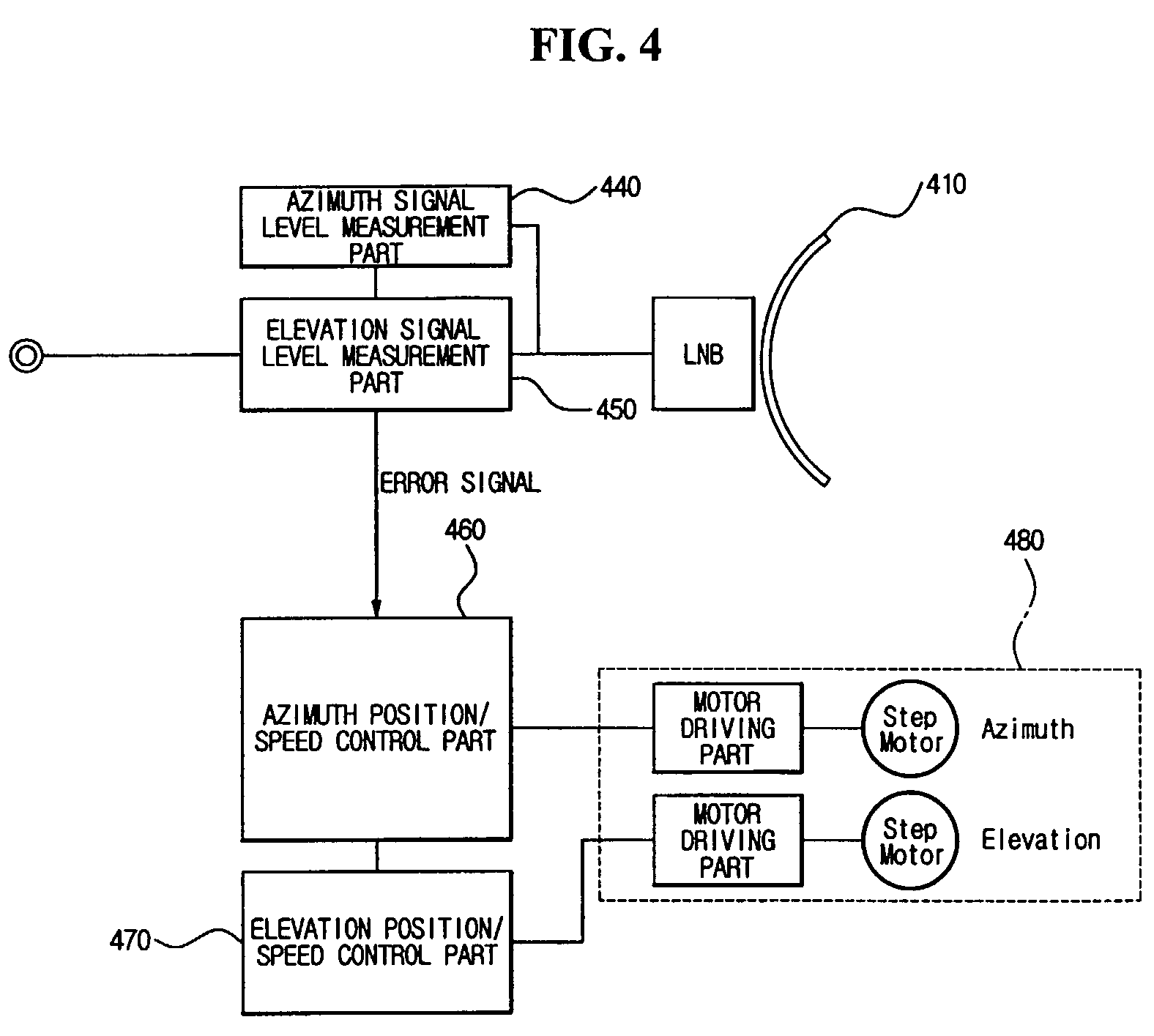

The present invention relates to a satellite tracking antenna system and a satellite tracking method. Step tracking in which the size of a satellite signal sampled in at least one position in which a reflector of the satellite tracking antenna system is tilted is compared to track a satellite is performed, and a measured value of the satellite signal sampled in a specific position in which the reflector is tilted in N-lth tracking and a measured value of the satellite signal sampled in the specific position in which the reflector is tilted in Nth tracking are averaged to compute a value. The reflector is driven according to the value to track the satellite, thereby minimizing a satellite tracking error caused by a sudden movement of a mobile body equipped with the satellite tracking antenna system.

Owner:INTELLIAN TECH

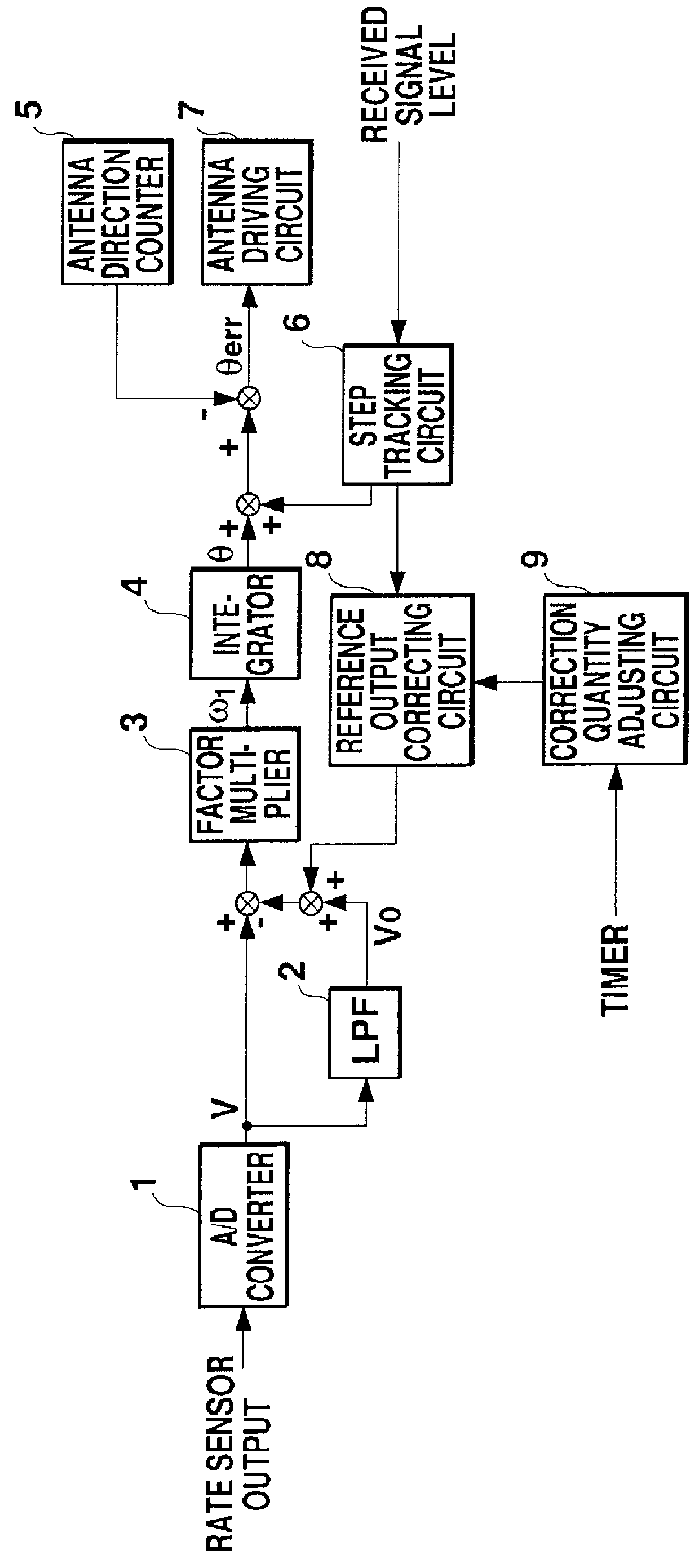

Antenna controller

InactiveUS6075482AWave based measurement systemsAntenna adaptation in movable bodiesSatellite trackingEngineering

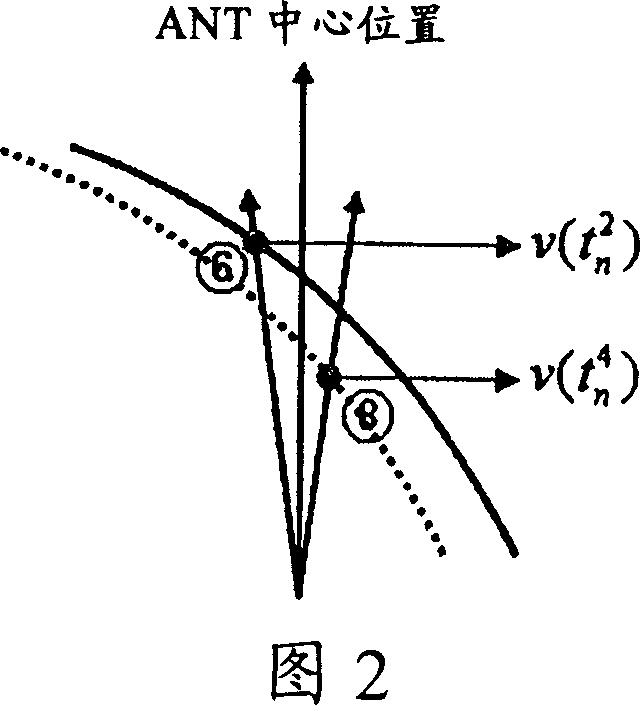

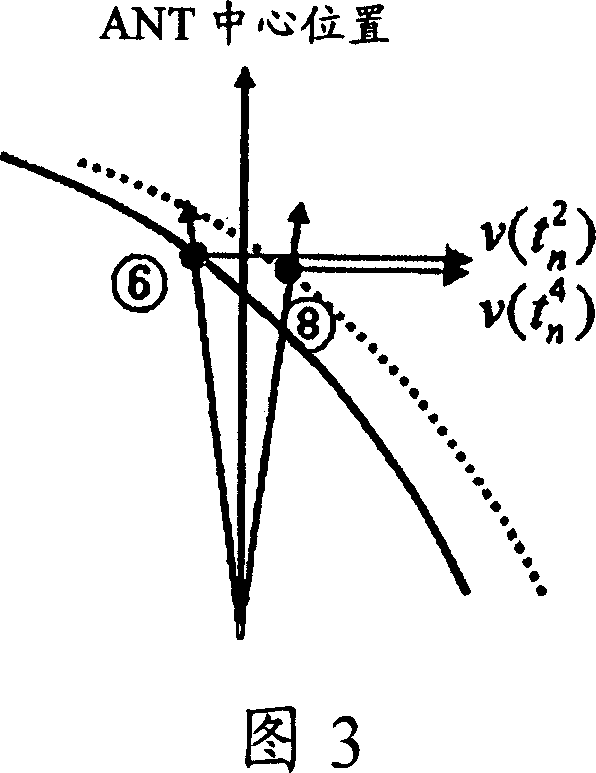

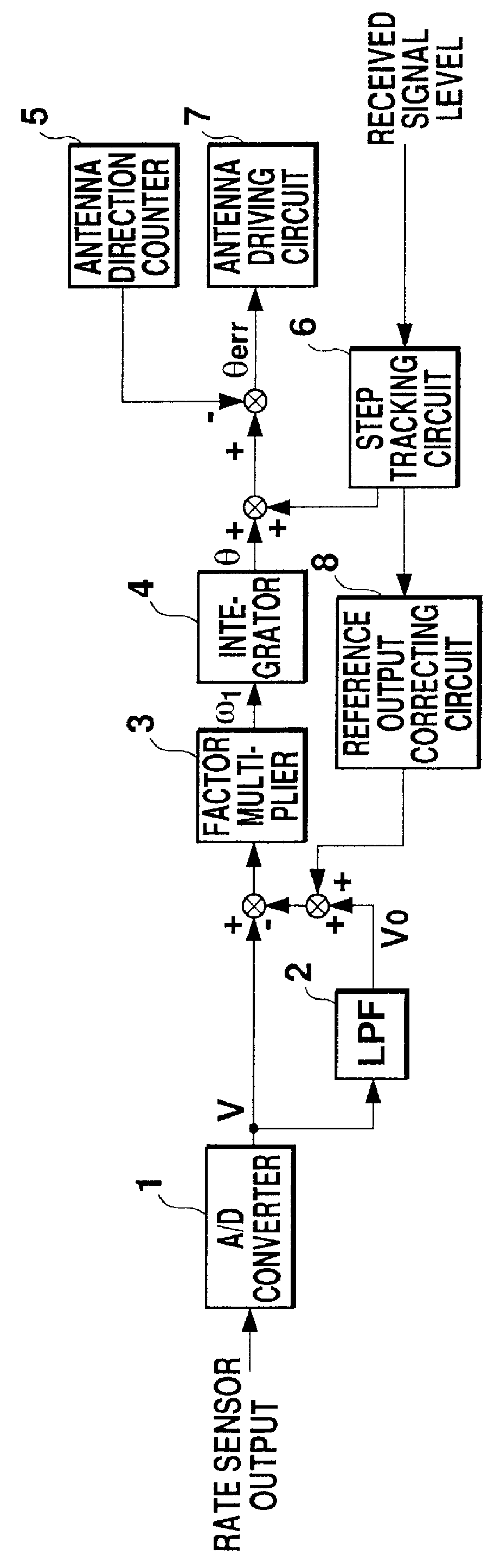

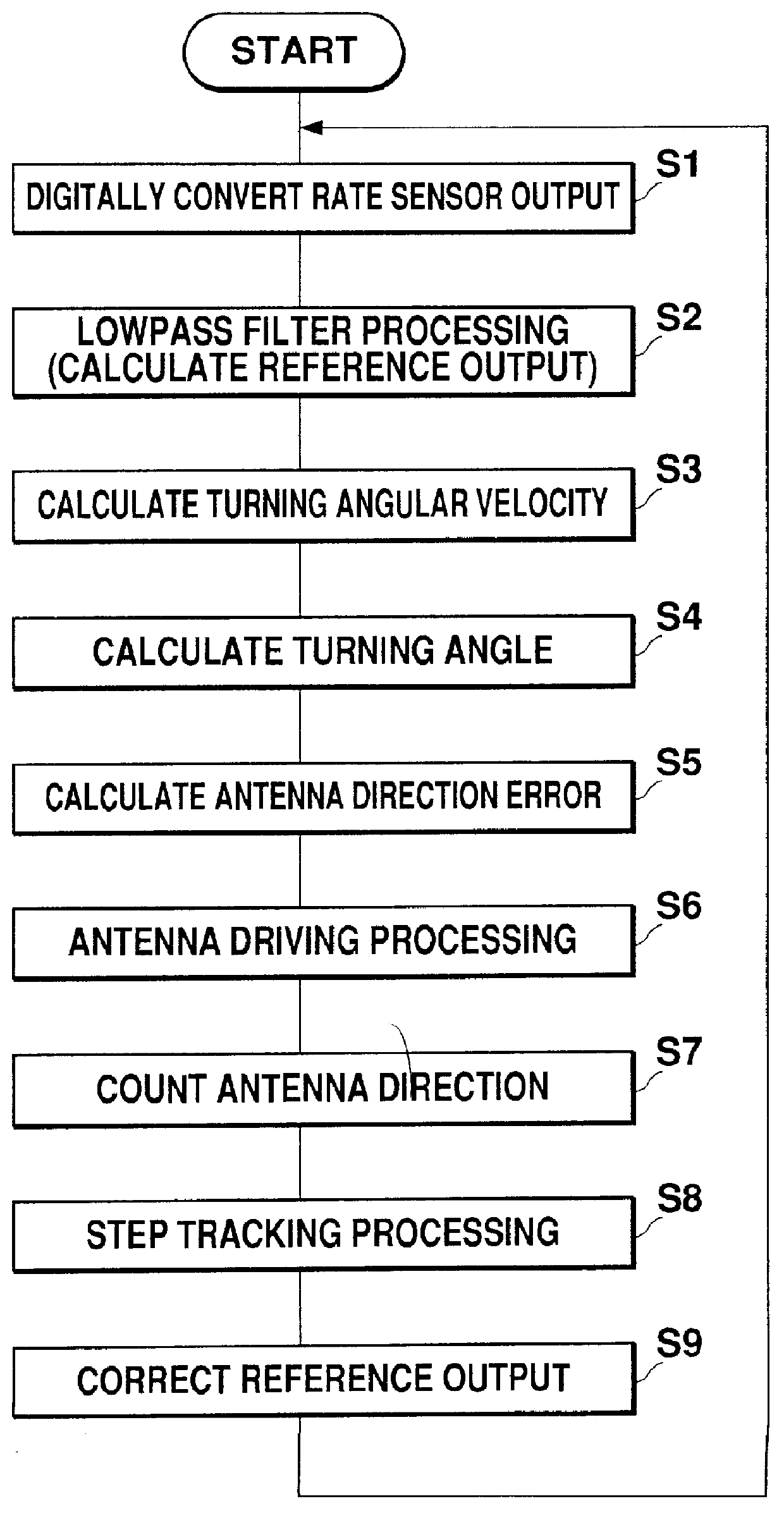

An antenna controller mounted on a movable body is provided for controlling antenna driving for satellite tracking. The antenna controller comprises a step tracking circuit for performing step tracking operation on a turning face of the movable body while receiving electromagnetic waves from a satellite, and for calculating an antenna pointing direction in which an intensity of the electric wave is strongest. An antenna driving circuit drives the antenna in the antenna pointing direction, while a reference output correcting circuit adds a correction quantity to a reference output of a rate sensor based on a result of the step tracking operation.

Owner:MITSUBISHI ELECTRIC CORP

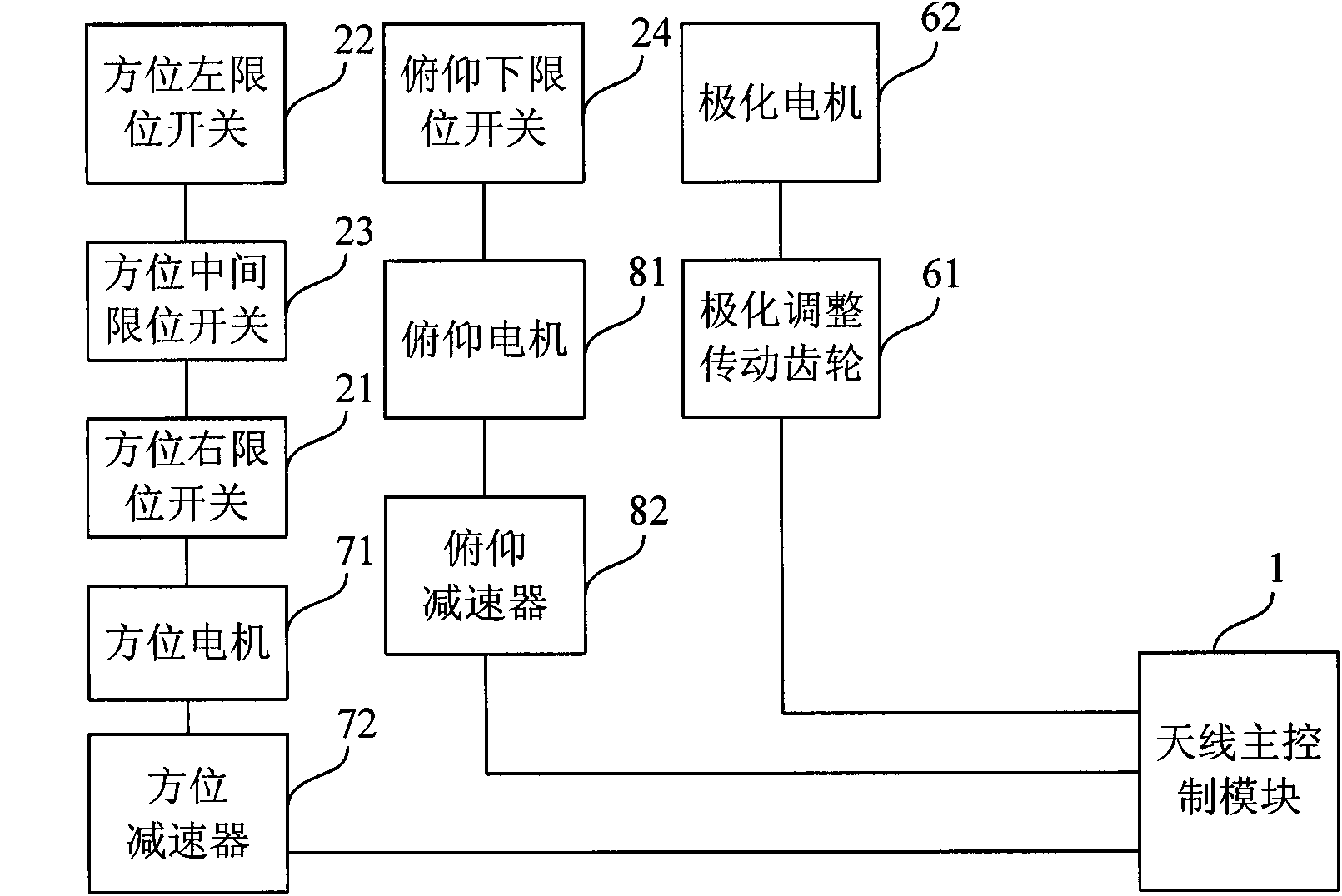

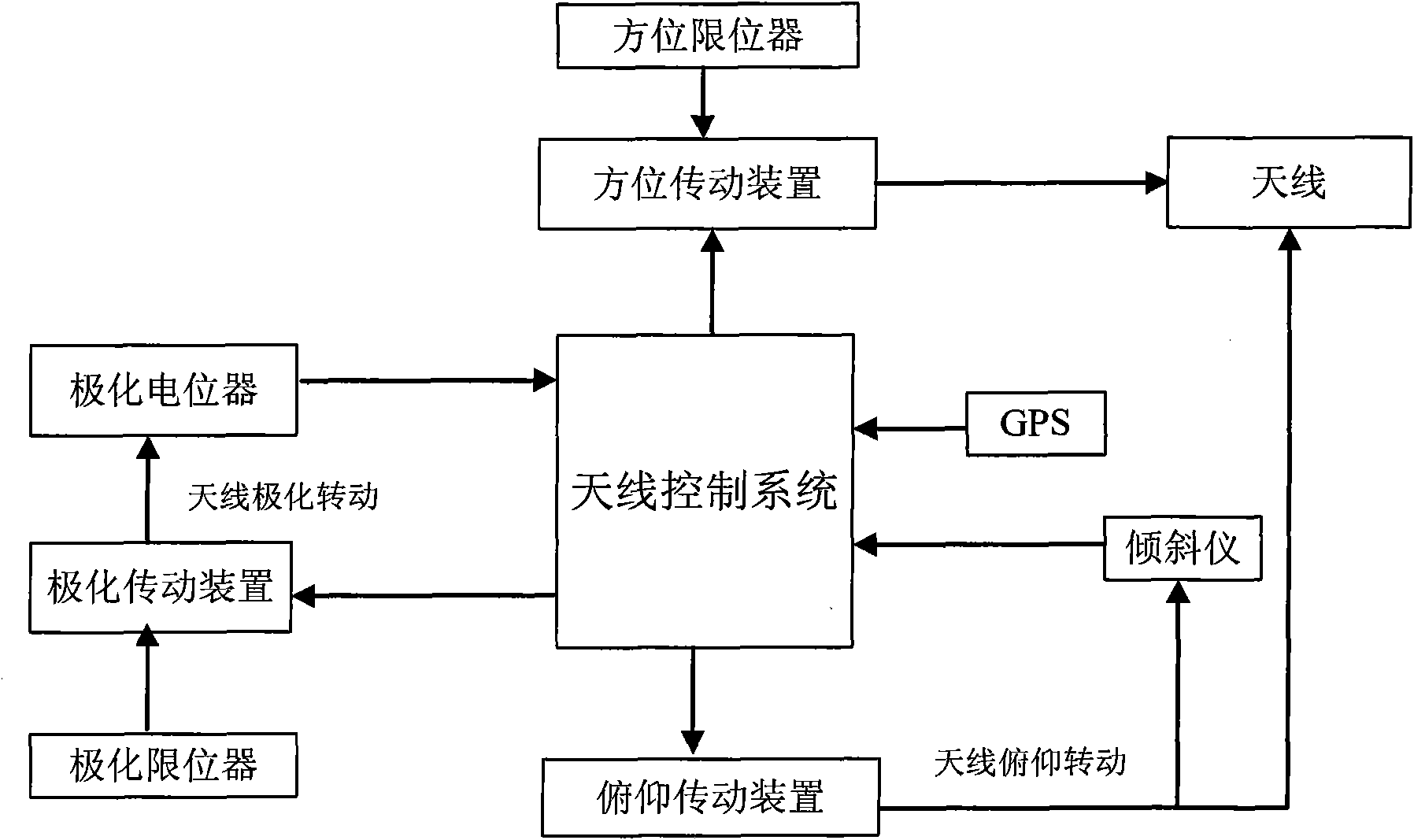

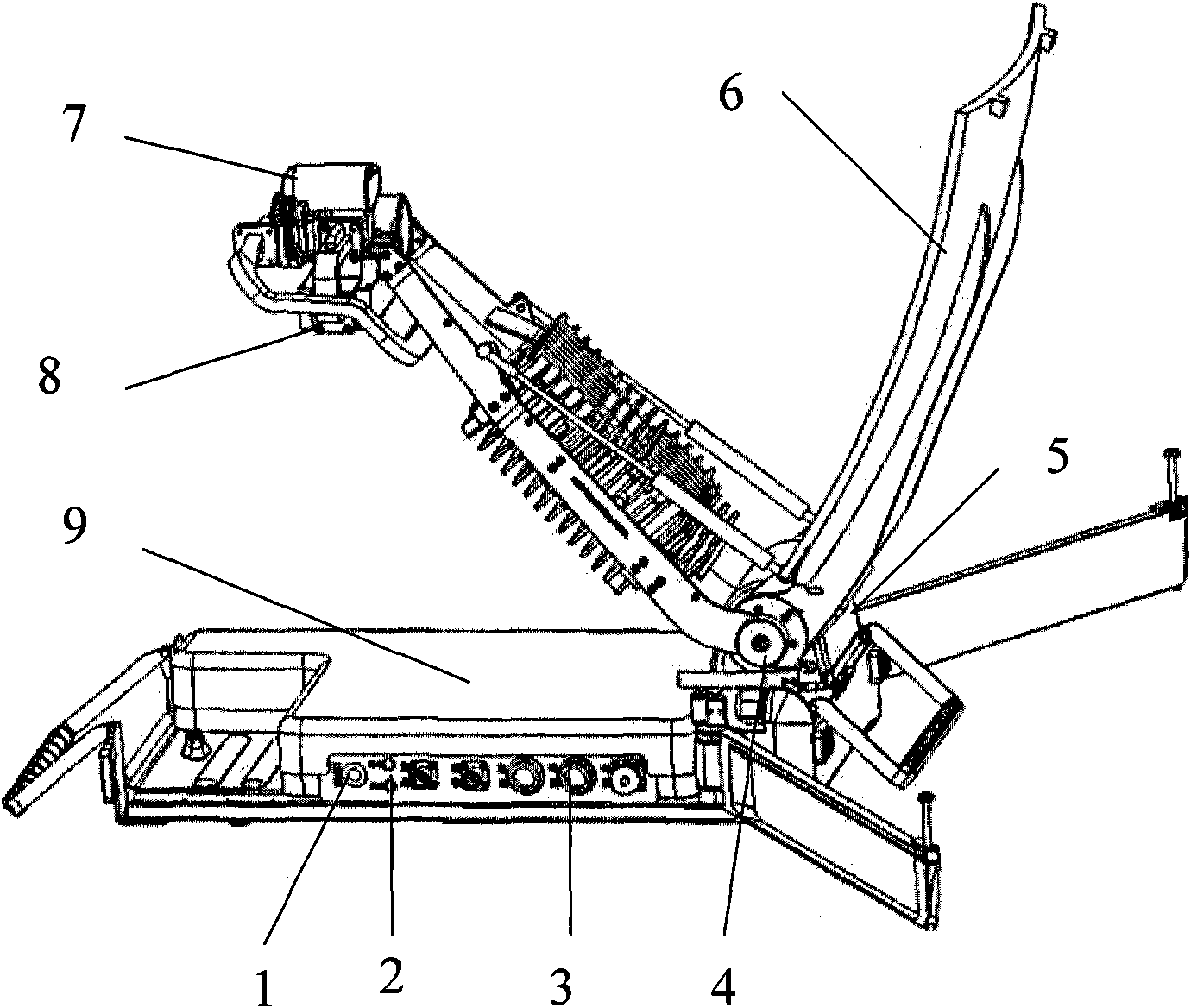

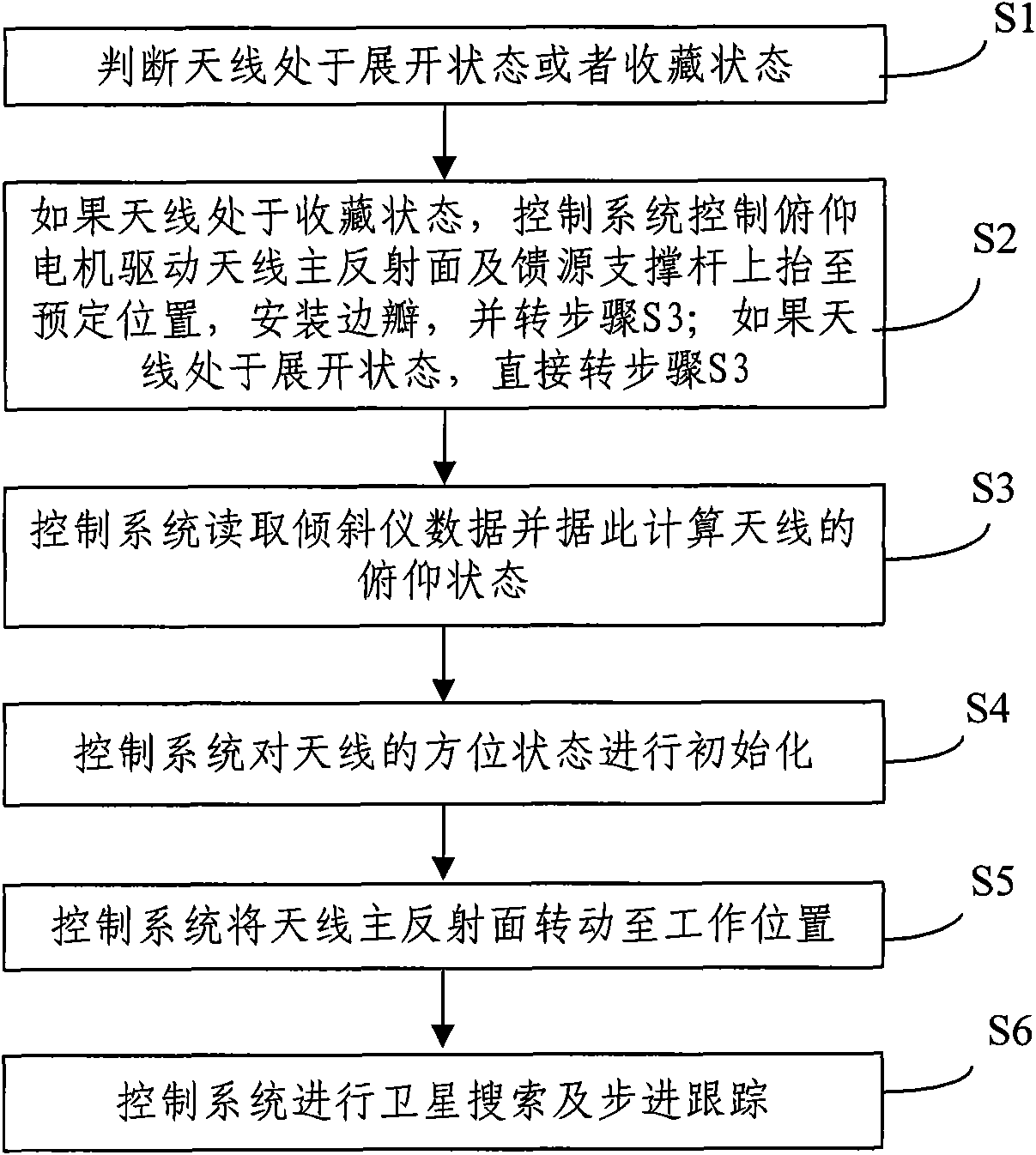

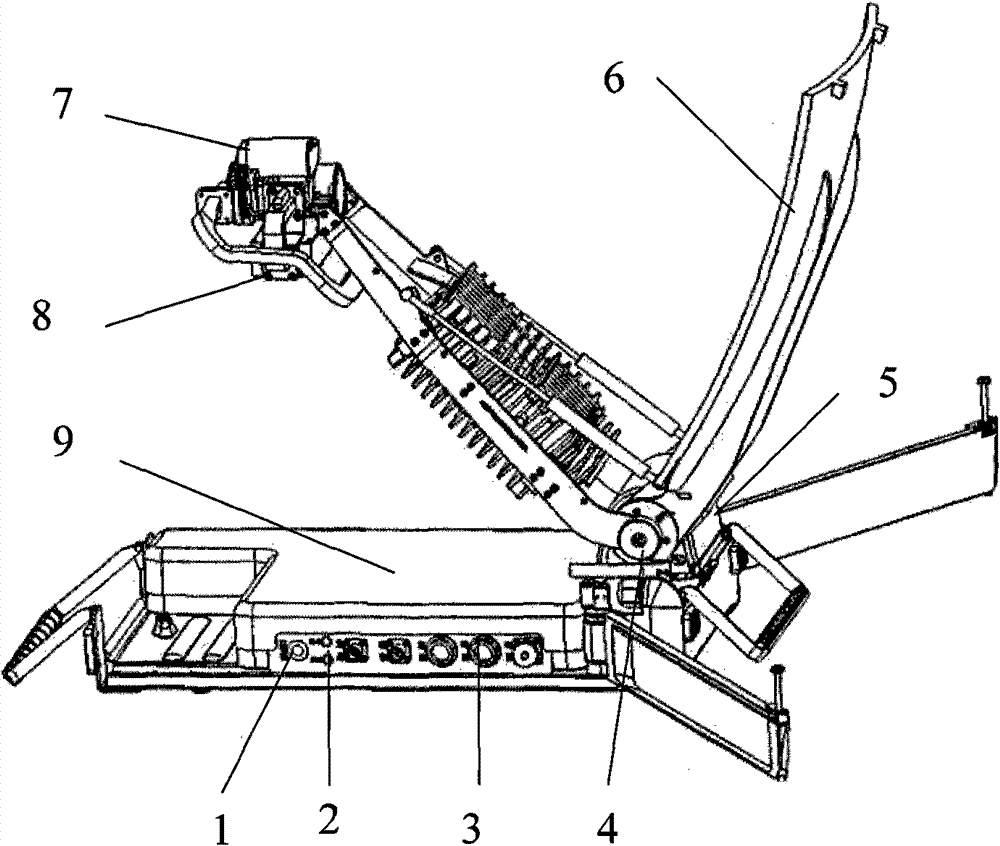

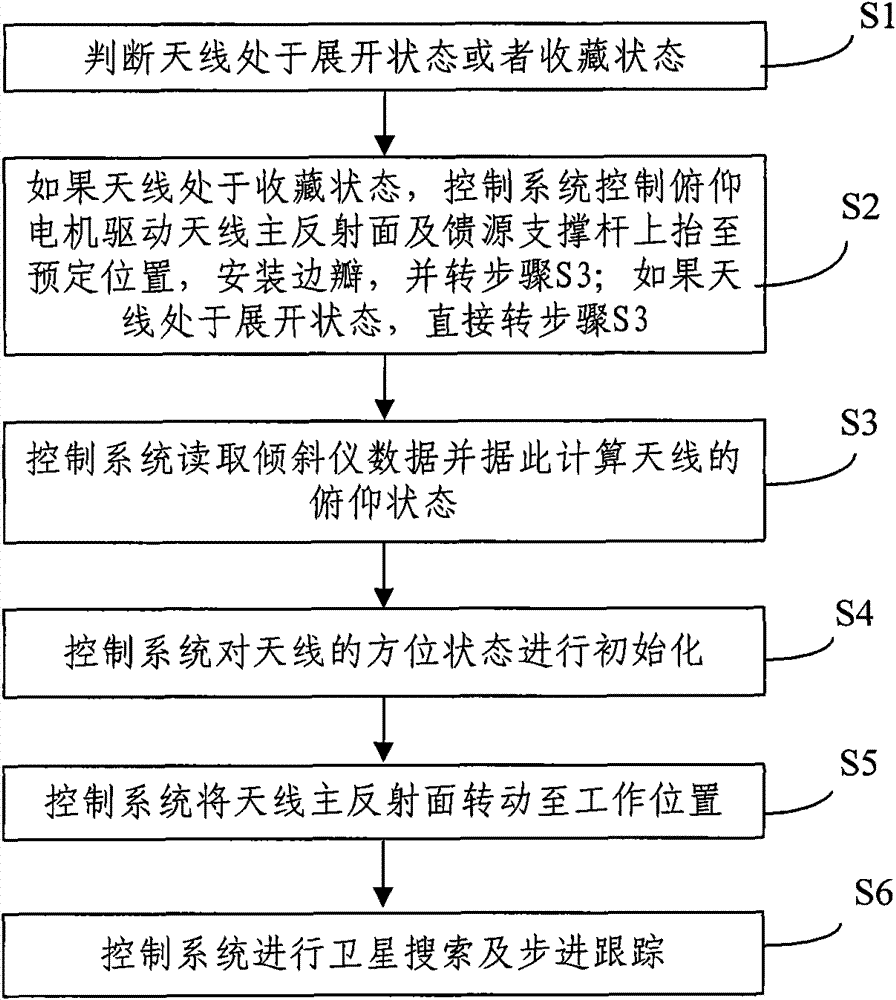

Method and system for seeking stars by using satellite antenna

InactiveCN101916118AAddress operational complexityFix stability issuesControl using feedbackAntennasMotor driveControl system

The invention discloses a method and a device for seeking stars by using a satellite antenna. The method comprises the steps of: S1, judging that the antenna is in an unfolded state or a folded state; S2, if the antenna is in the folded state, controlling a main reflecting surface of a pitching motor driving antenna and a feed source supporting rod to be lifted to the preset positions by using a control system, installing side lobes and carrying out the step S3; if the antenna is in the unfolded state, directly carrying out the step S3; S3, reading the data of an inclinometer and calculating the pitching state of the antenna according to the data by using the control system; S4, initializing the direction state of the antenna by using the control system; S5, rotating the main reflecting surface of the antenna to the working position by using the control system; and S6, carrying out satellite search and step tracking by using the control system. The invention achieves the purpose of accurate star seeking by adopting the control system for control the polarization, the direction and the pitching of the satellite antenna and solves the problems of complicated operation, instable performance and low star-matching speed of the satellite antenna in the prior art.

Owner:AKD COMM TECH

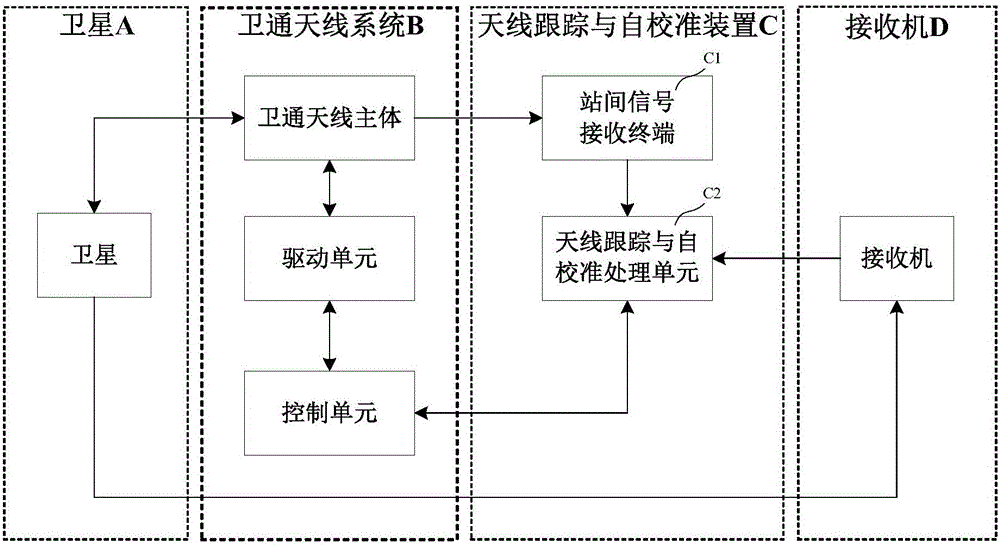

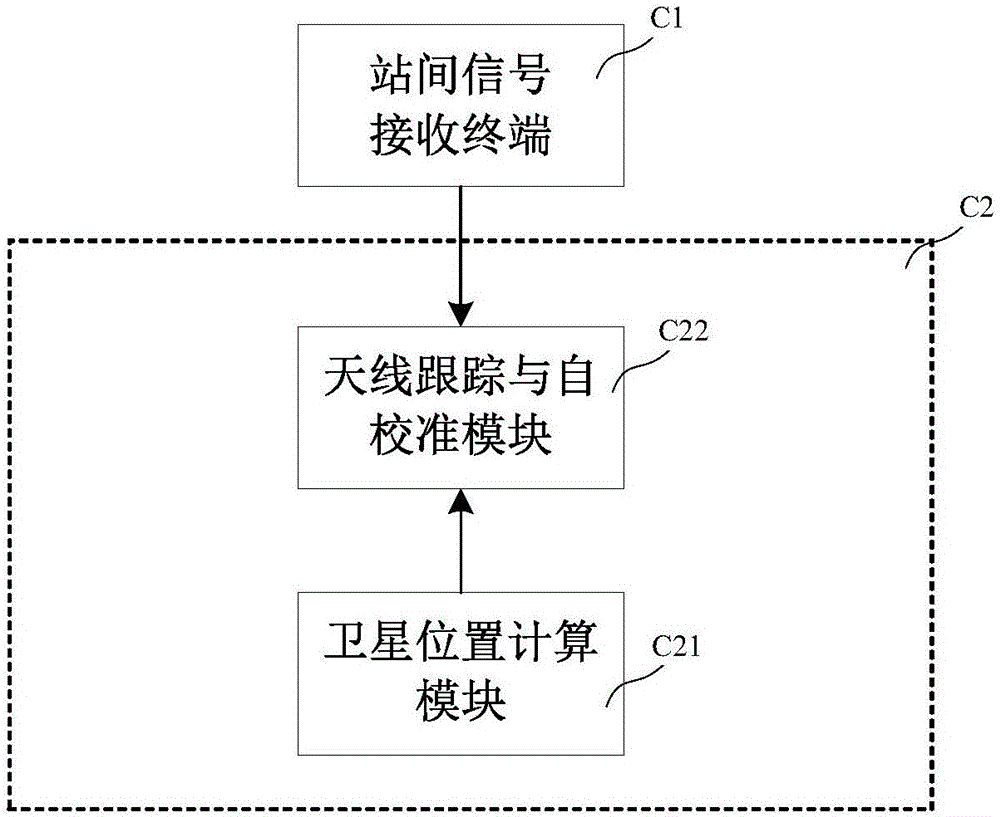

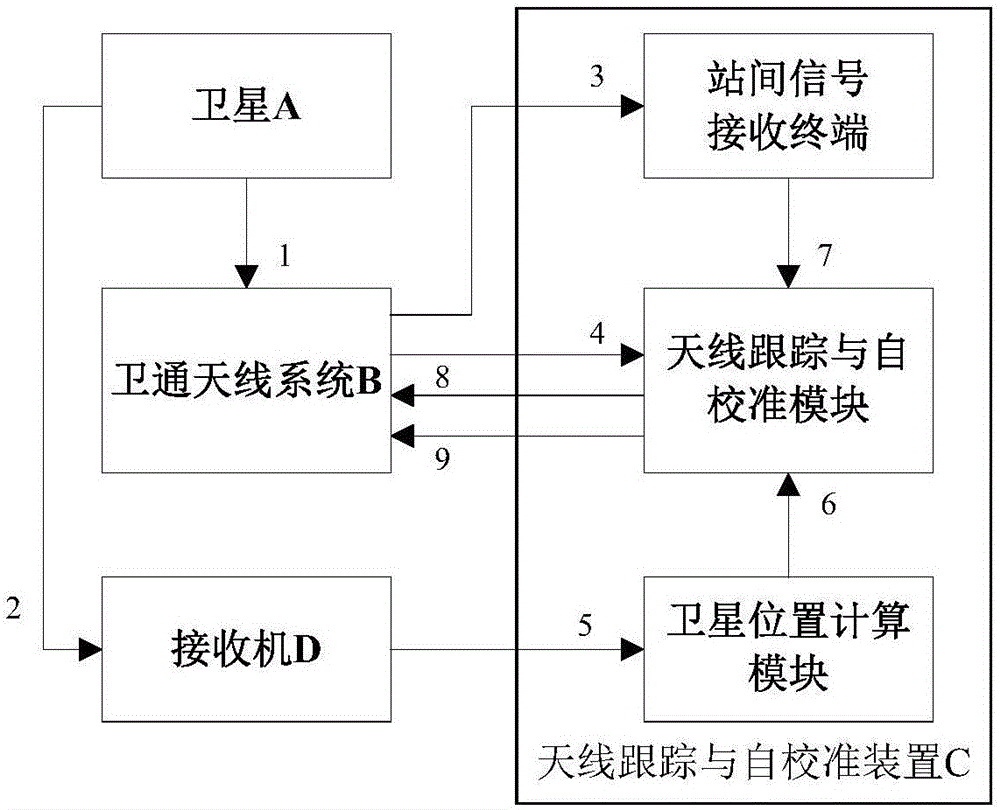

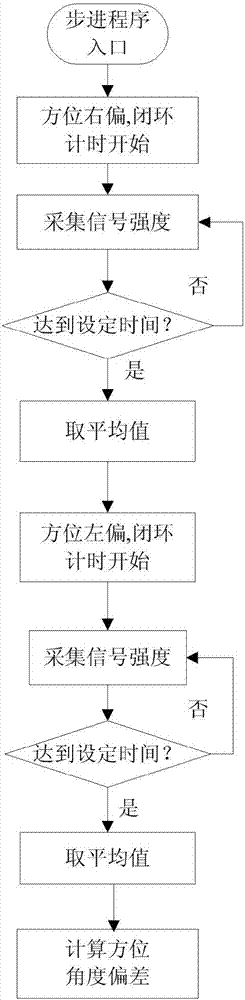

Antenna tracking and self-calibration apparatus and method for satellite communications among stations

InactiveCN106597473AImprove reliabilityNo more tracking failuresTransmitters monitoringSatellite radio beaconingNatural satelliteTechnician

The invention provides an antenna tracking and self-calibration apparatus and method for satellite communications among stations in order to target the deficiency of the antenna step-tracking mode used in the previous satellite communication field among satellite navigation system stations and the deficiency of conducting antenna pointing and calibrating by technicians in phases. Therefore, the apparatus and method of the invention directly utilize the navigated network information of the satellite to calculate the azimuth and pitch angle information of the satellite accurately and then send the information to a satellite antenna for tracking. Compared with the previous step-tracking mode, the case involving tracking failure will not repeat itself, therefore, increasing the reliability of the satellite communication antenna tracking among the satellite navigation system stations. In the tracking process, through the determination of the signal power received by the antenna to determine the pointing station of the antenna and according to the requirement to complete the self-calibration of the antenna pointing, it is possible to avoid the deficiency of calibration and maintenance by technicians going to the stations in person.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

Satellite tracking antenna system and method therefor

ActiveUS7446721B2Accurate trackingPrecisely and effectively trackAntenna adaptation in movable bodiesDirection findersSatellite trackingEnvironmental geology

The present invention relates to a satellite tracking antenna system and a satellite tracking method. Step tracking in which the size of a satellite signal sampled in at least one position in which a reflector of the satellite tracking antenna system is tilted is compared to track a satellite is performed, and a measured value of the satellite signal sampled in a specific position in which the reflector is tilted in N−1th tracking and a measured value of the satellite signal sampled in the specific position in which the reflector is tilted in Nth tracking are averaged to compute a value. The reflector is driven according to the value to track the satellite, thereby minimizing a satellite tracking error caused by a sudden movement of a mobile body equipped with the satellite tracking antenna system.

Owner:INTELLIAN TECH

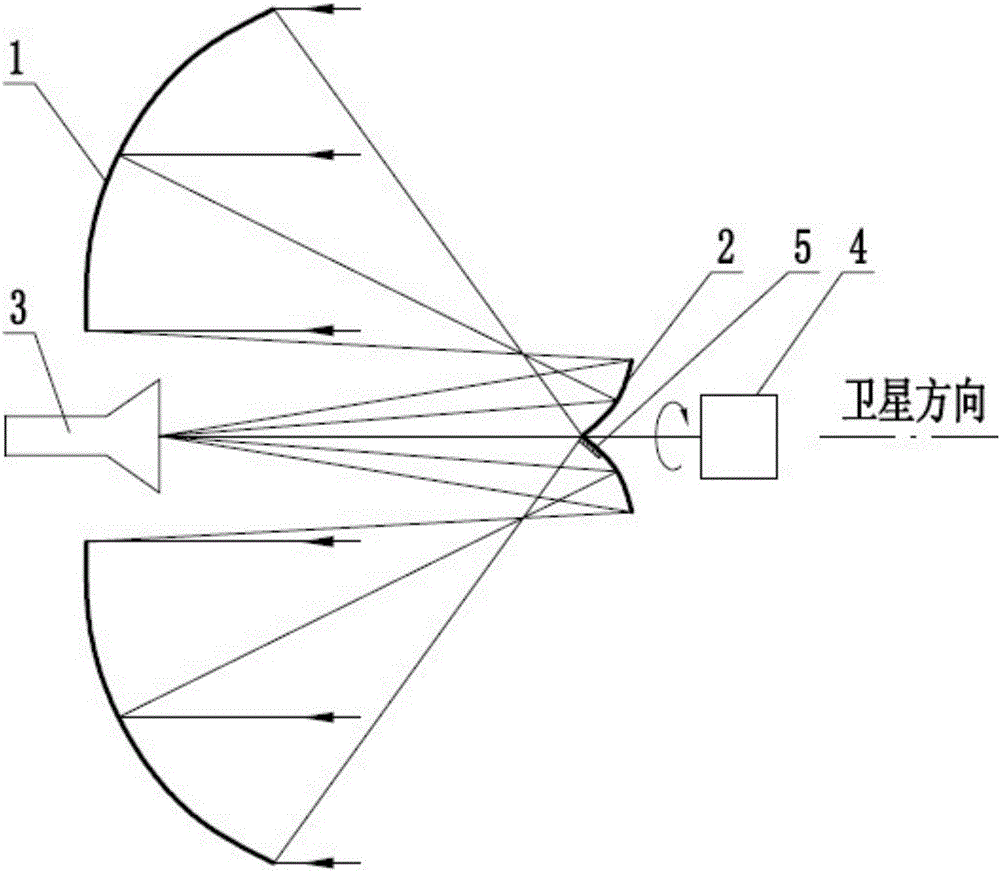

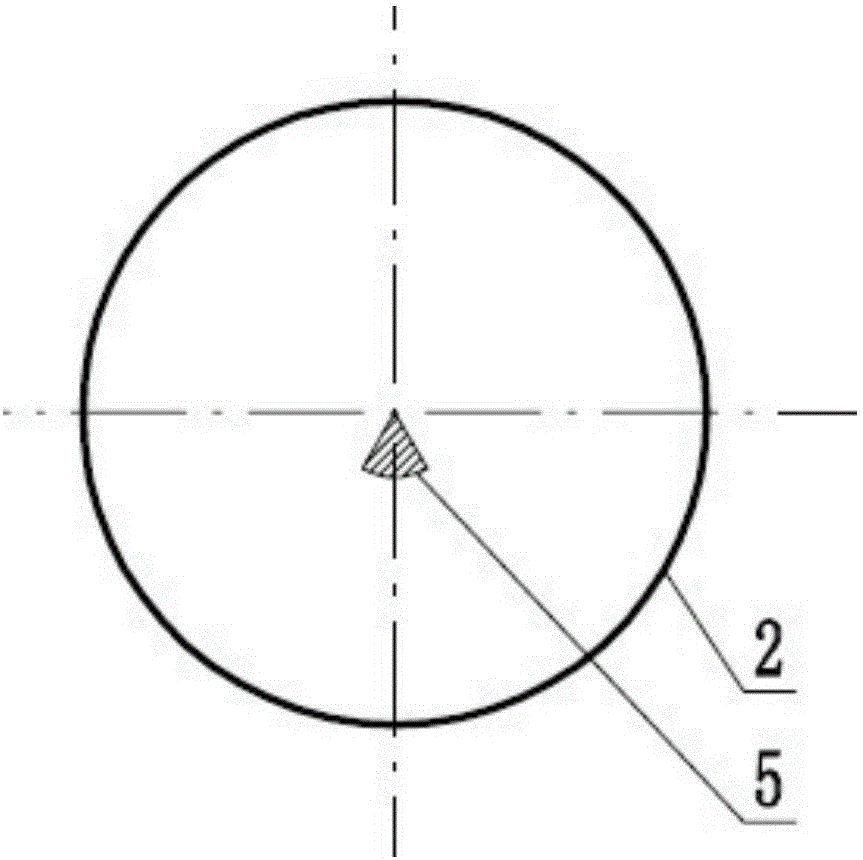

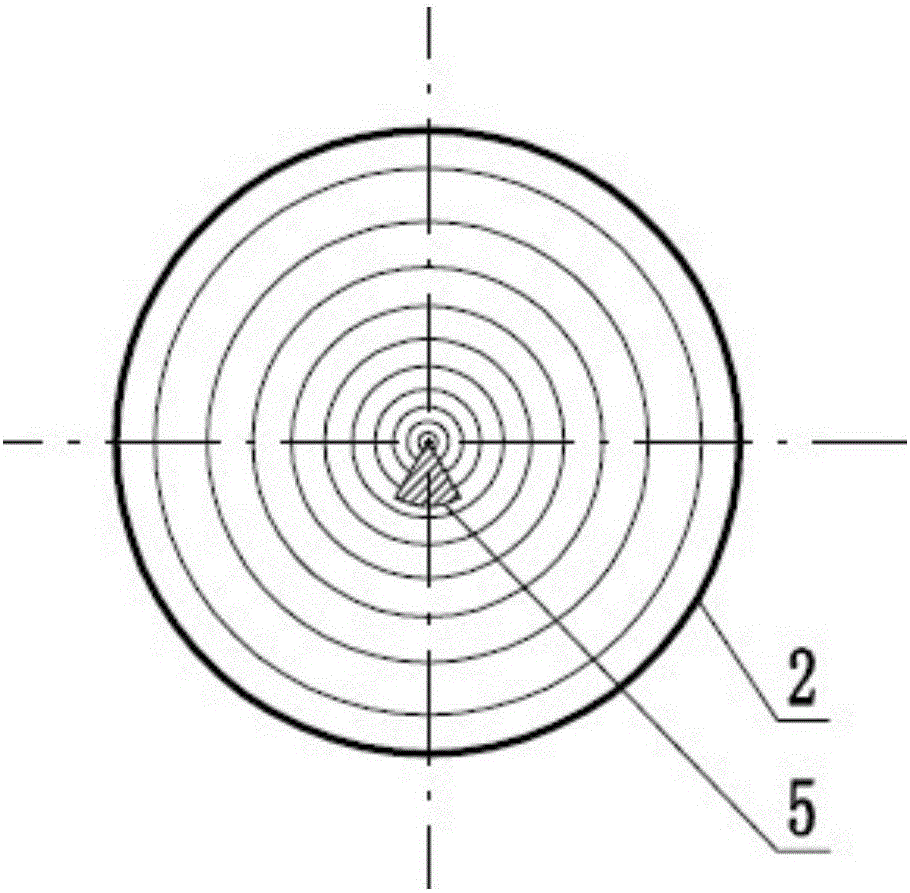

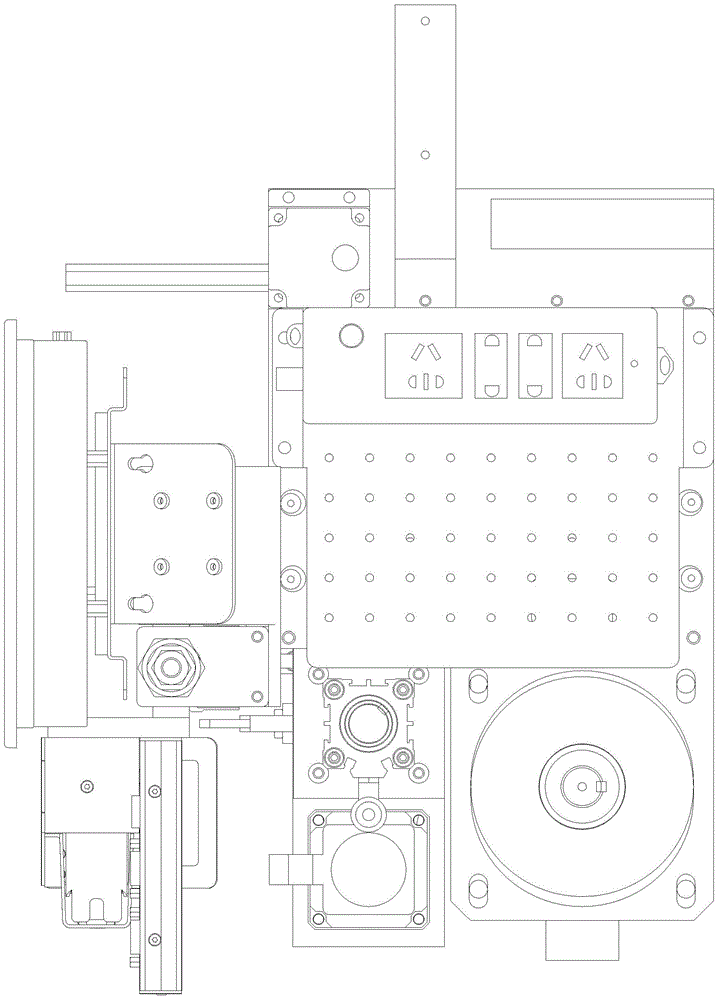

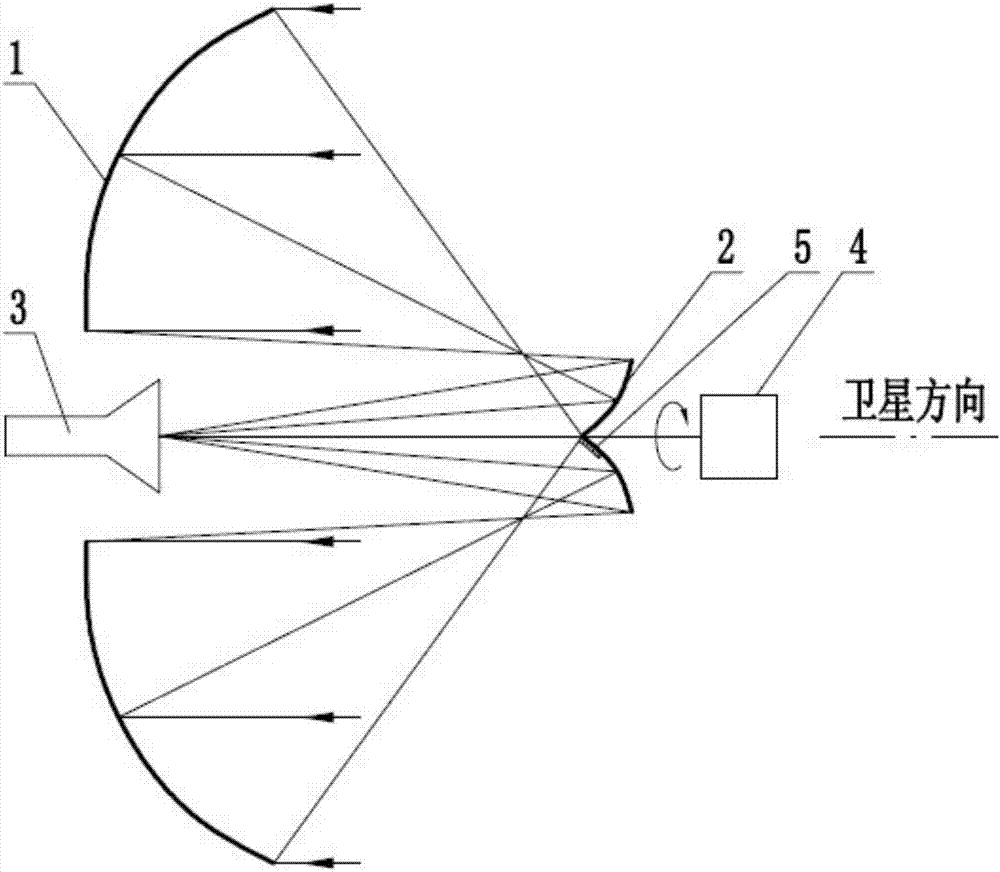

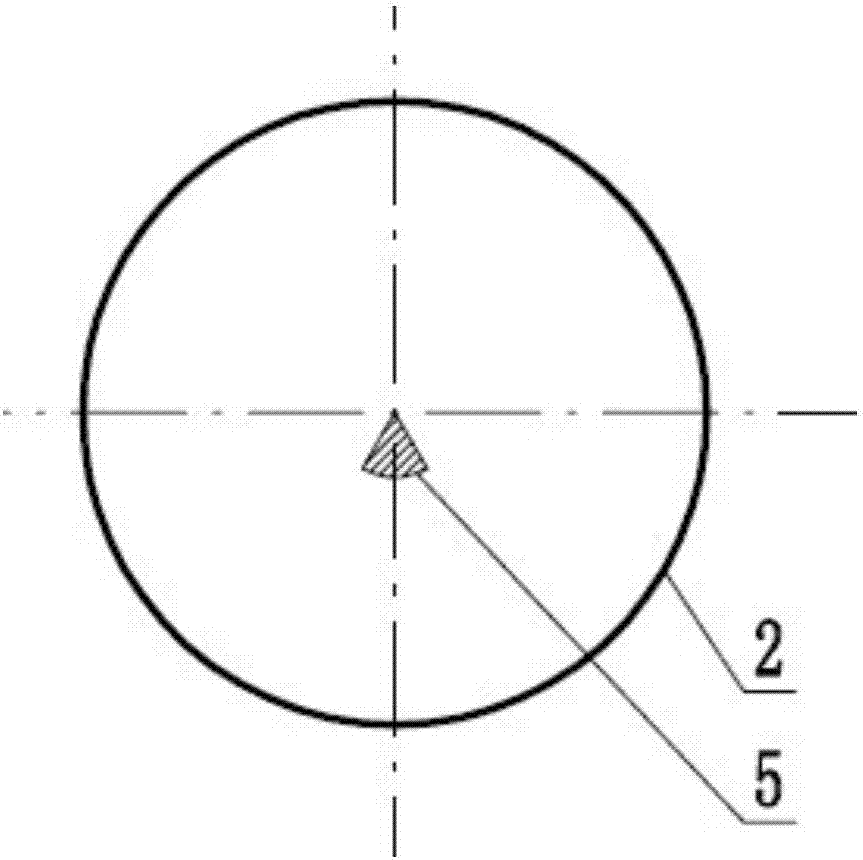

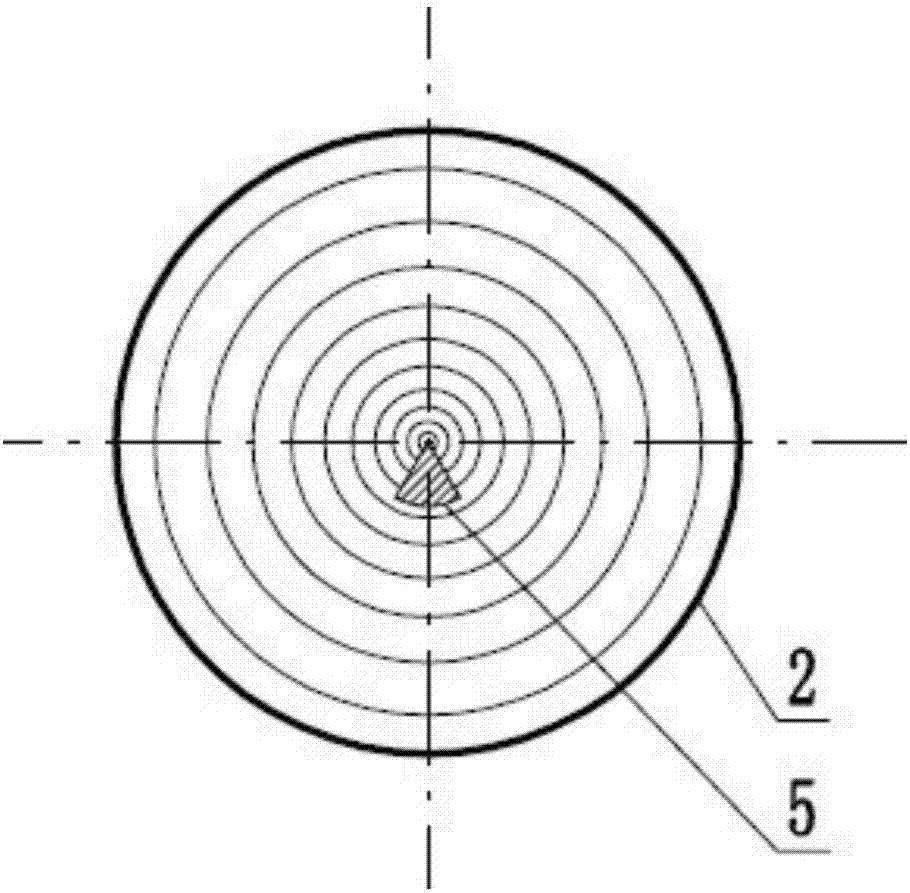

Double-reflecting surface satellite antenna rotation missing area tracking system and method

The present invention discloses a double-reflecting surface satellite antenna rotation missing area tracking system and method for solving the problems existing in the automatic tracking system of a satellite antenna. The system comprises a main reflecting surface, a sub-reflecting surface, and a feeding source wherein the main reflecting surface is provided with a servo tracking unit and a main control unit. The main reflecting surface, the sub-reflecting surface and the feeding source are arranged concentrically with either the main reflecting surface or the sub-reflecting surface capable of rotating around an axis and provided with a rotation mechanism; the rotating main reflecting surface or the sub-reflecting surface is provided with a signal local failure region in a biased manner. Compared with step tracking, the system and the method of the invention has high precision and responds quickly. In contrast with cone scanning and tracking, the main reflecting surface and the sub-reflecting surface are coaxially arranged, which reduces the side lobe, interference from adjacent star and increases the applicability. Compared with mono-pulse, through the use of a signal local failure region for rotation and biased signals, it is possible to obtain sinusoidal like signals whose type and strength change periodically. Simple in structure, the manufacturing cost of the system is also low.

Owner:SINOTRUST MARINE ZS SATELLITE COMM CO LTD +1

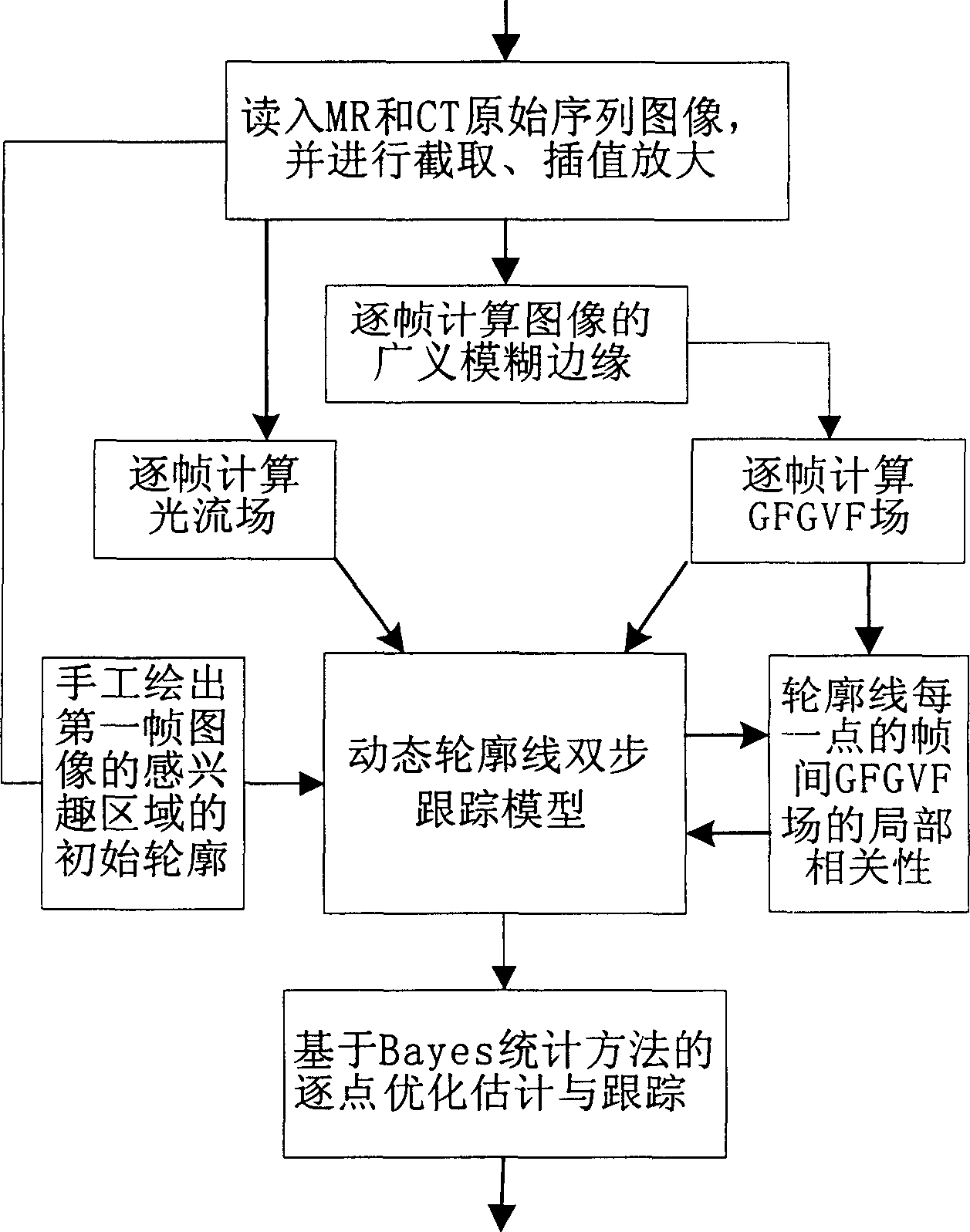

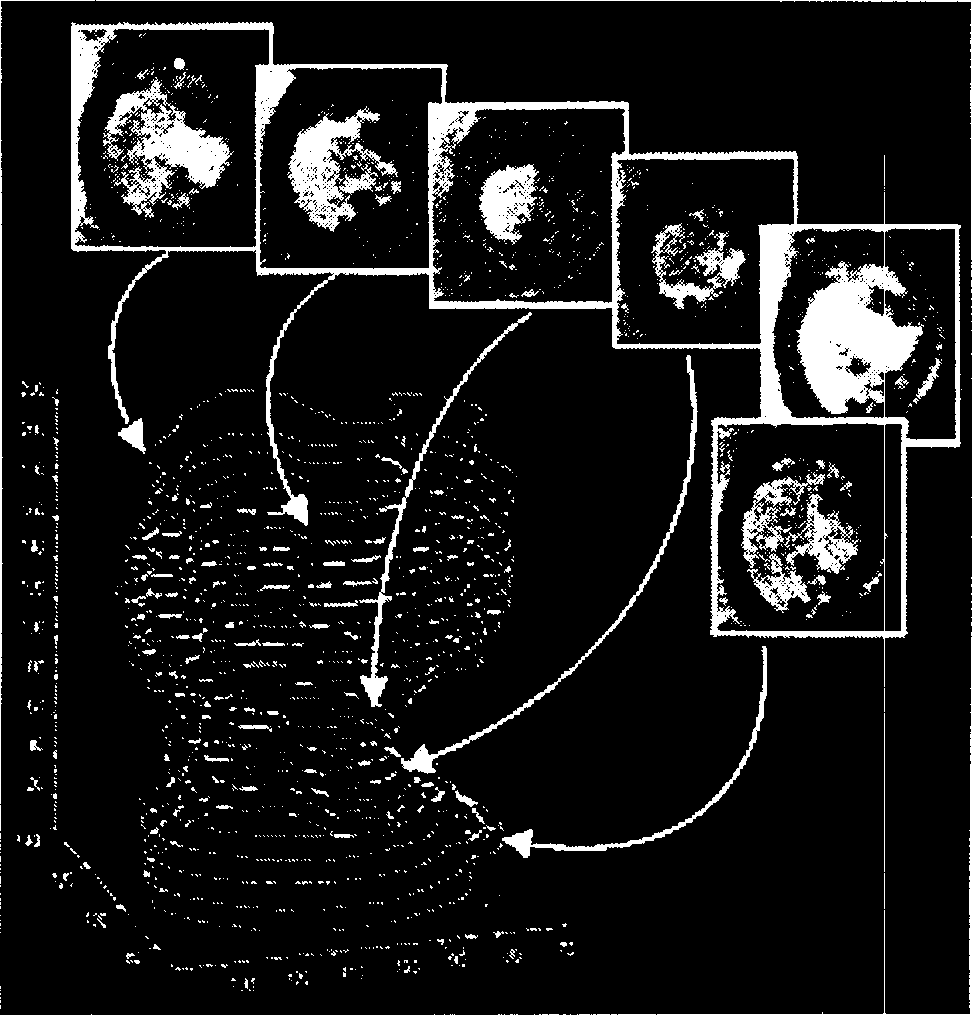

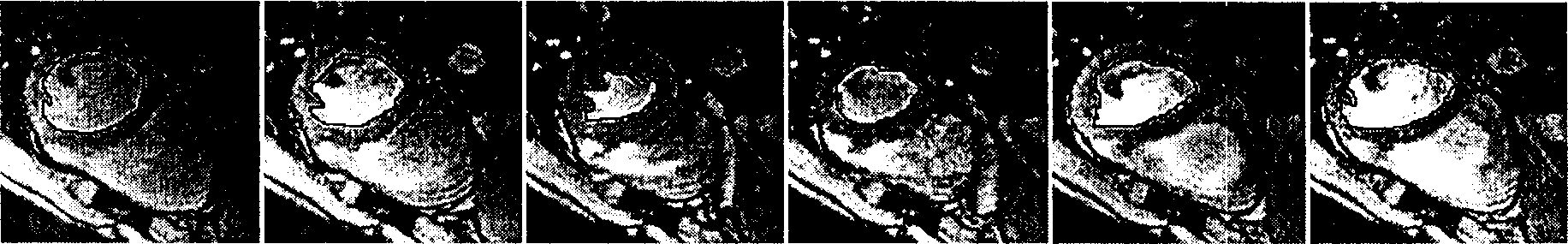

Medical sequence image motion estimation method based on generalized fuzzy gradient vector flow field

InactiveCN1516051ASo smoothPromote recoverySpecial data processing applicationsEstimation methodsMaximum a posteriori estimation

The present invention discloses a medical sequence image motion estimation method based on the generalized fuzzy gradient vector flolw field, it includes the following steps: 1. obtaining and sequence image; 2. obtaining generalized fuzzy gradient vector flow field of double-step tracking model, and locak correlation of generalized fuzzy gradient vector flow field and optical flowvector field; 3. manually drawing the outline of edge of interested zone of first frame image; 4. under the action of three kinds of external force fields using said double-step tracking model to frame-by-frame track the drawn edge outline of interested zone; 5. combining the above-mentioned tracking result of outline, and using maximum posteriori estimation to make optimizational estimation and tracking of every point on the outline so as to obtain the optimum motion track of the point.

Owner:广州宜诚数字医疗系统有限公司

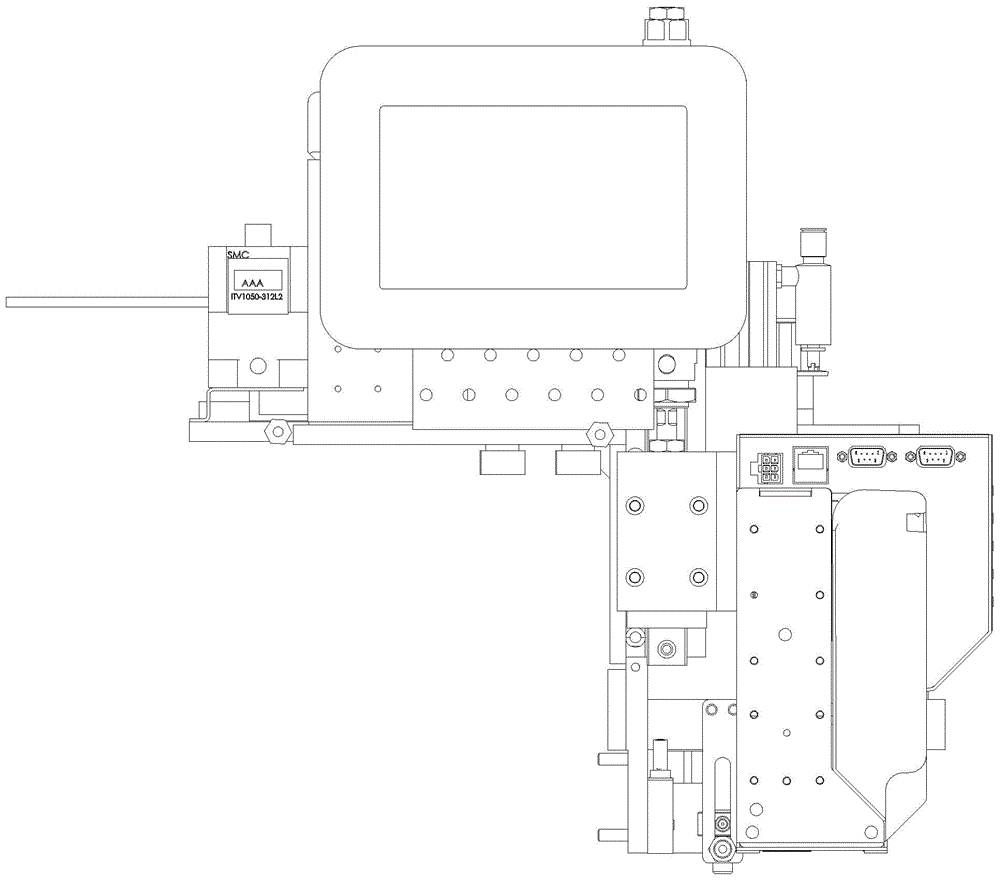

Moving carrier signal receiving system

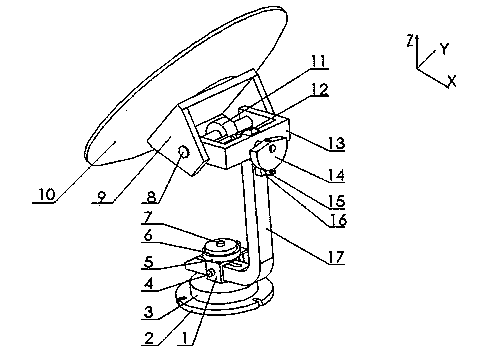

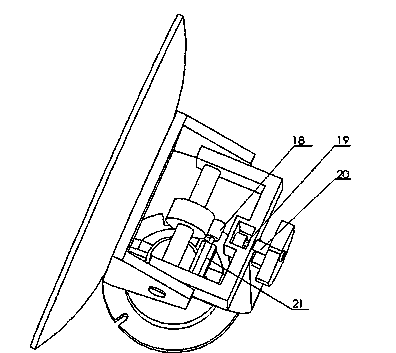

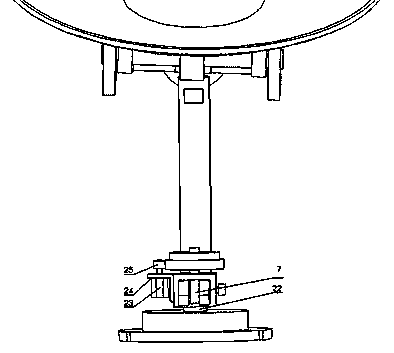

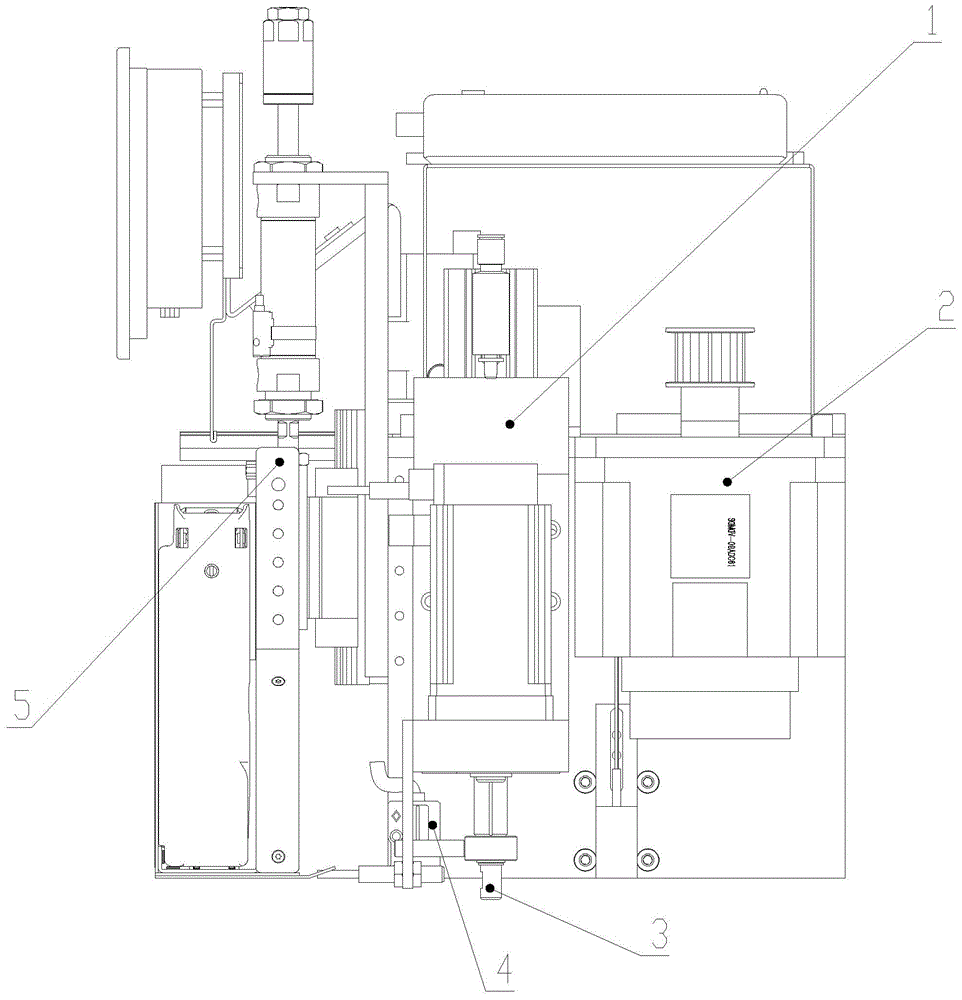

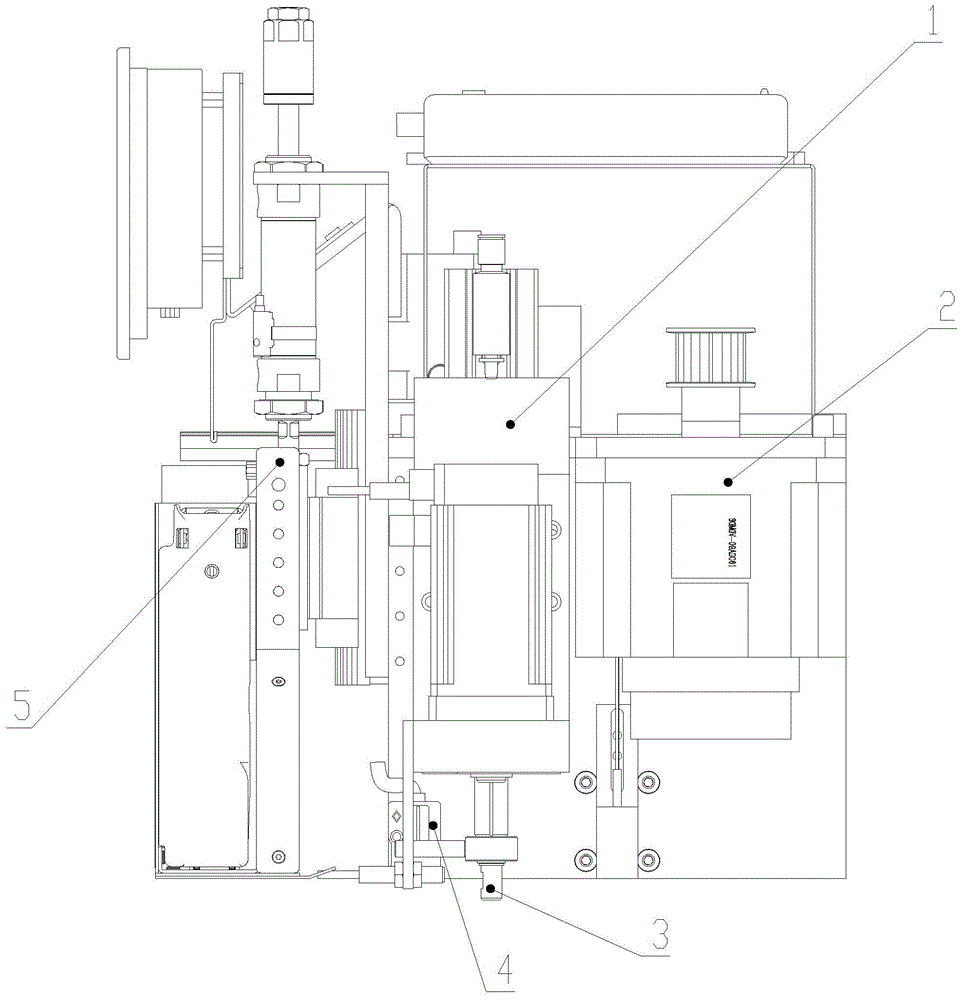

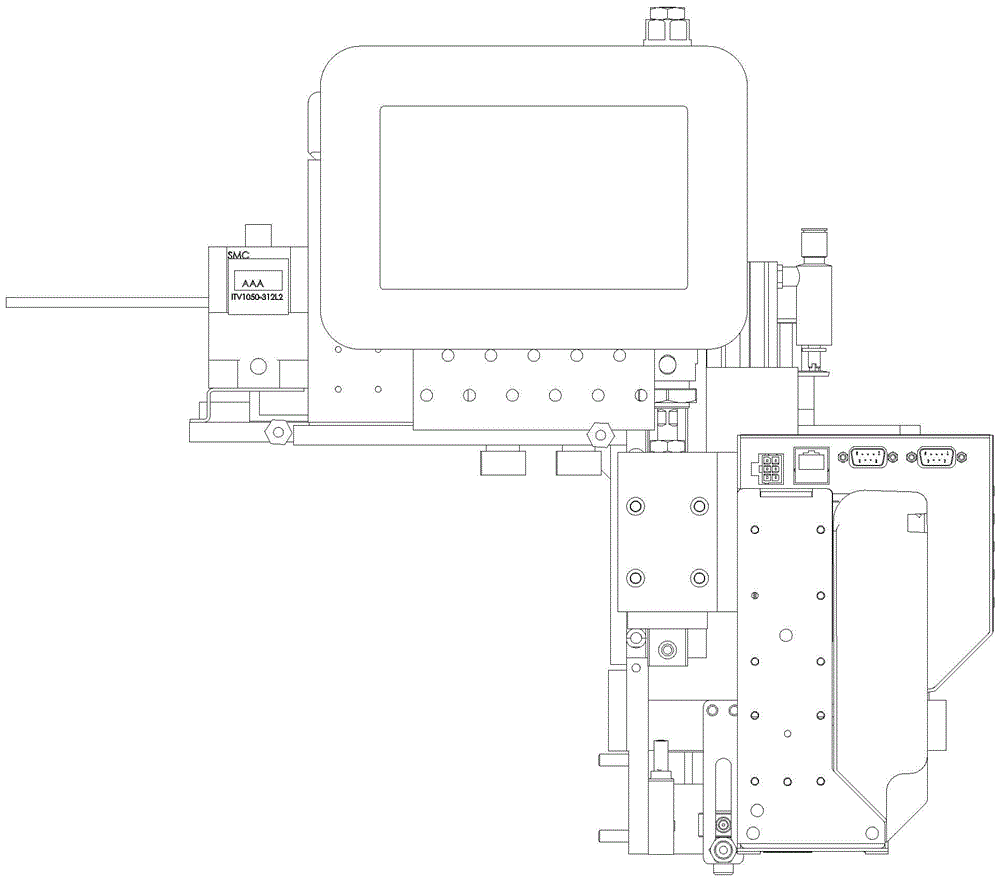

InactiveCN103811870ACompact structureImprove anti-interference abilityAntenna adaptation in movable bodiesGyroscopeCarrier signal

The invention discloses a moving carrier signal receiving system, comprising an antenna (10), a mounting base (2), an absorber (3), a cross rolling axis frame (13), a pitch axis frame (9), an azimuth axis frame (17), three sets of direct current brushless torque motor reduction gears, three piezoelectric gyroscopes, three photoelectric encoders, a sensor, a position and posture measuring system and the like. According to the system, a three-axis structure including the pitch axis, the cross rolling axis and the azimuth axis is adopted, a tracking mode of stepping tracking is adopted, and the embedded system development technology, the driving and control integrated technology and the multimoding intelligent control algorithm are utilized, so that the high stability and tracking feature are achieved. The disturbance of the moving carrier to a satellite receiving antenna is isolated, the stable orientation of the satellite antenna in the moving process is maintained, so that the requirement of receiving satellite signals in the wild or a long journey is met, and the moving carrier signal receiving system is particularly applicable to vehicle-mounted systems and shipborne systems with complex work environments.

Owner:上海市闵行区知识产权保护协会

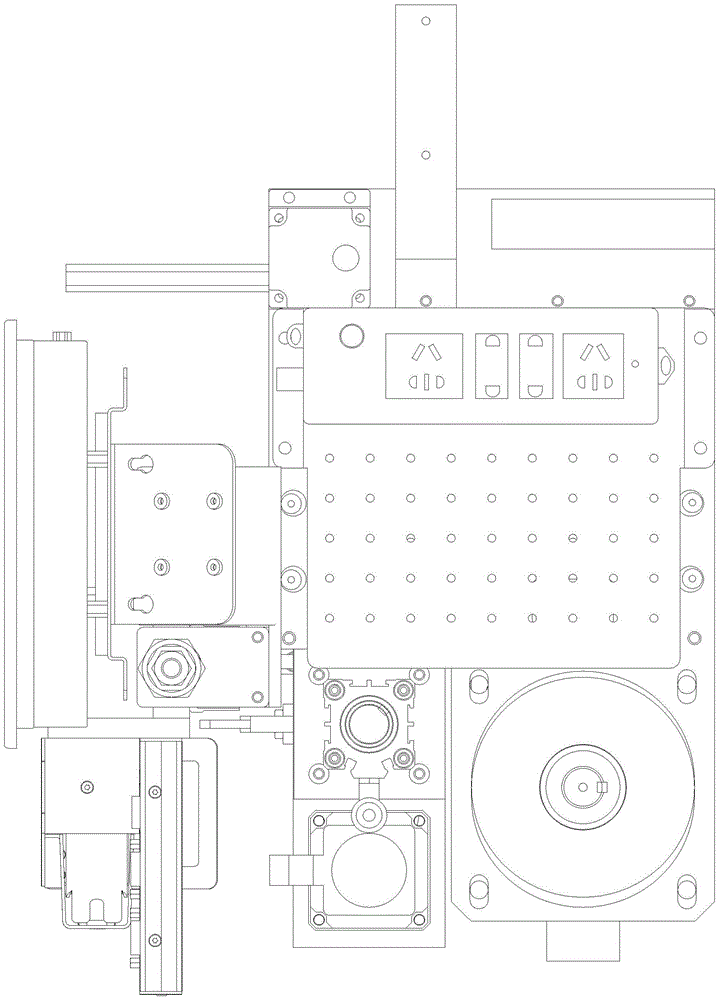

Multifunctional machine for glass cutting, code-spurting, carving and thickness measurement

The invention provides a multifunctional machine for glass cutting, code-spurting, carving and thickness measurement and relates to the field of glass machinery. The multifunctional machine comprises a worktable top of the machine; the multifunctional machine is characterized in that longitudinal traveling mechanisms are arranged on the two sides of the worktable top, a cross beam is erected between the longitudinal traveling mechanisms on the two sides, a transverse traveling drive mechanism is arranged on the transverse beam, and a multifunctional handpiece is arranged on the transverse traveling drive mechanism and comprises a code-spurting mechanism, a precision cutter box, a thickness measurement mechanism and a traveling power transmission mechanism. The multifunctional machine for glass cutting, code-spurting, carving and thickness measurement is a multifunctional glass machining machine and has the functions of cutting, code-spurting, carving and thickness measurement simultaneously; a glass cutter or a carving cutter can be mounted in the precision cutter box and can be used for cutting and carving glass; the code-spurting mechanism is capable of realizing spray printing of the content needed by a customer on plate glass and used for step tracking and workpiece identification.

Owner:ANHUI YINRUI GLASS MACHINERY

A dual-reflector satellite antenna rotation gap tracking system and method

Disclosed are a rotation missing plot tracking system and method for a double-reflection-surface satellite antenna, which are used for solving the deficiency of an existing satellite antenna automatic tracking system, characterized by comprising a main reflection surface, a secondary reflection surface and a feed source, wherein the main reflection surface is provided with a servo tracking unit and a main control unit; the main reflection surface, the secondary reflection surface and the feed source are coaxially arranged; one of the main reflection surface and the secondary reflection surface can rotate around an axial centre and is provided with a rotation mechanism; and the rotating main reflection surface or secondary reflection surface is eccentrically provided with a signal local-failure zone. Compared with stepped tracking, the present invention has a high precision and is quick in response; compared with conical scanning tracking, a main reflection surface and a secondary reflection surface are coaxially arranged, thereby decreasing a side lobe, reducing the interference of an adjacent satellite and improving the applicability; and compared with single-pulse tracking, by using a rotating and eccentrical signal local-failure zone, a quasi-sinusoidal signal of a model intensity period change can be acquired, which has a simple device and a low cost.

Owner:SINOTRUST MARINE ZS SATELLITE COMM CO LTD +1

Environment emergency simulation drilling system based on VR technology

InactiveCN107170320AMeet business needsEnhanced interactionInput/output for user-computer interactionCosmonautic condition simulationsHuman–robot interactionDrilling system

The invention discloses an environment emergency simulation drilling system based on the VR technology. The environment emergency simulation drilling system is mainly composed of a three-dimensional scene implementation system, a step tracking subsystem, a smoke thermal simulation subsystem, a body sign remote measurement and poison gas detection subsystem and a control and display subsystem. The environment emergency simulation drilling system based on the VR technology has the advantages of being close to emergency demand, convenient in human-computer interaction, simple and convenient in equipment configuration, customizable in scene and scientific in assessment system so that parallel simulation can be realized.

Owner:江苏汇环环保科技有限公司

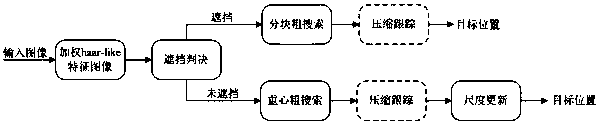

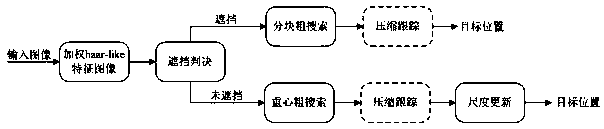

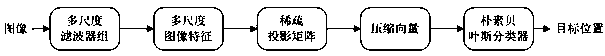

Scale adaptive target tracking method based on fast compressive tracking algorithm

ActiveCN108062557AImprove robustnessEnhance anti-occlusion abilityCharacter and pattern recognitionPattern recognitionContext model

The invention discloses a scale adaptive target tracking method based on a fast compressive tracking algorithm. Firstly, a context model is used to weight a quasi-Haar feature, and the robustness of the quasi-Haar feature towards illumination changes is enhanced; then, stepped tracking is adopted, the anti-blocking ability of the algorithm and the ability of the algorithm handing the target scalechanges are enhanced, and the real-time performance of the algorithm is also kept; and finally, a scale adaptive method is put forward, and stable tracking on the scale change target is realized. Goodrobustness is achieved in conditions of target scale change, target appearance change and target being blocked, the frame frequency can be ensured to be about 39 frames per second, and requirements of real-time performance are met.

Owner:青岛青咨工程咨询有限公司

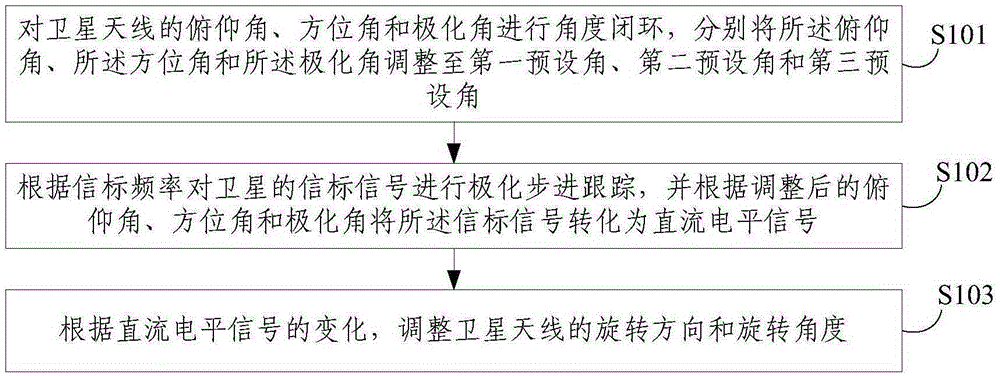

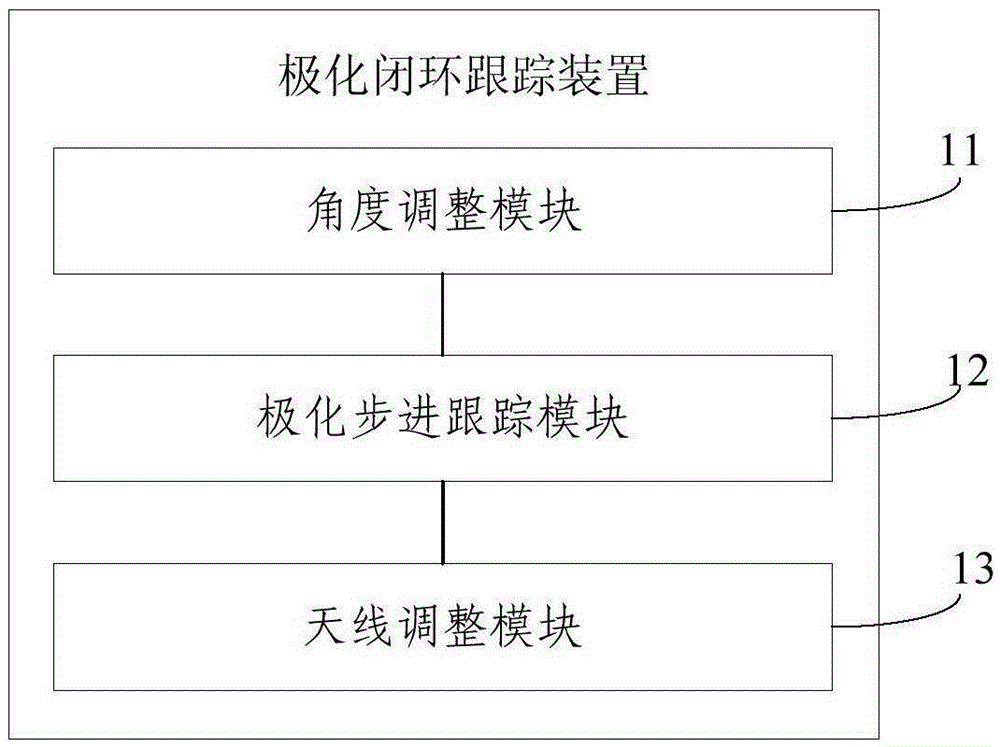

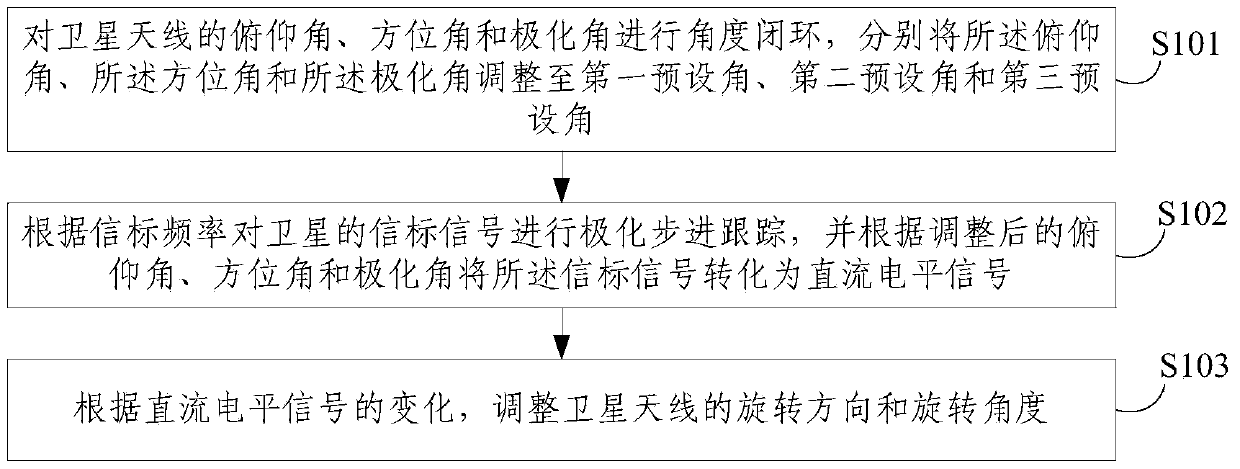

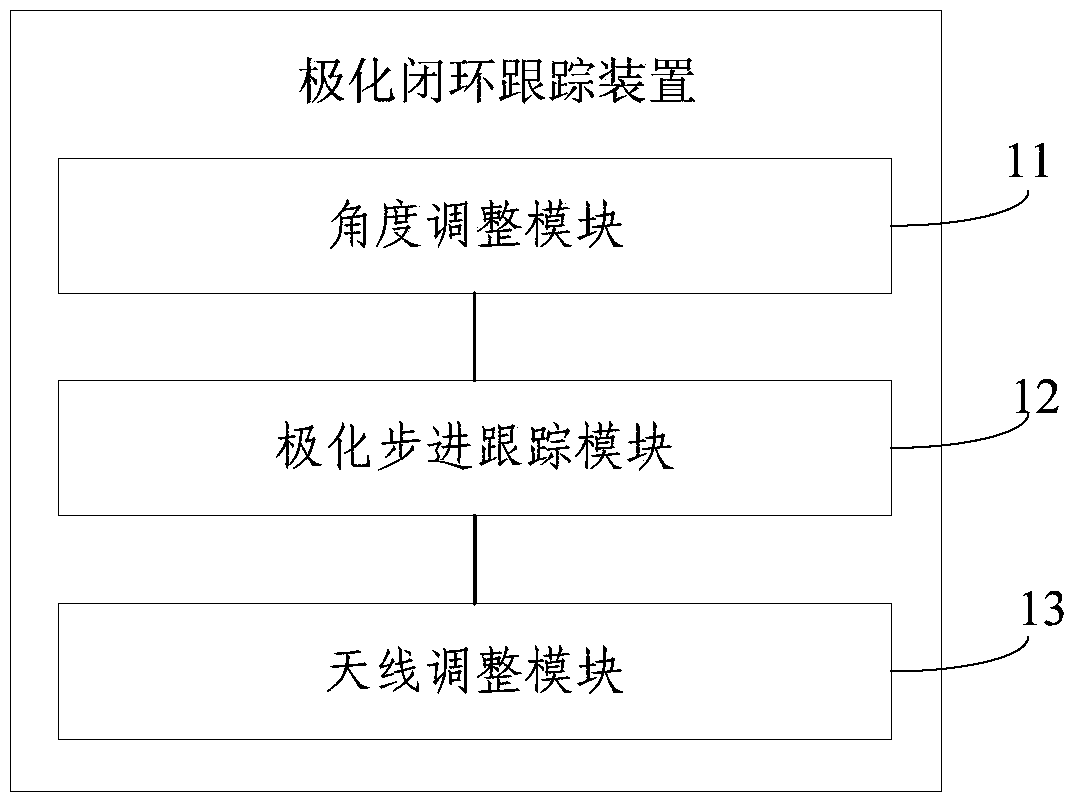

Satellite antenna polarized closed loop tracking method and device

ActiveCN105337039AReduces two-way interference issuesImprove communication qualityAntennasCommunication qualityLoop closing

The invention discloses a satellite antenna polarized closed loop tracking method and a device. The satellite antenna polarized closed loop tracking method comprises steps performing angle loop closing on a pitch angle, an azimuth and a polarized angle of the satellite antenna, regulating the pitch angle, the azimuth and the polarized angle to a first preset angle, a second preset angle and a third preset angle, performing polarized stepping tracking on a beacon signal of a satellite according to a beacon signal frequency, converting the beacon signal to a DC level signal according to the regulated pitch angle, the azimuth and the polarized angle, and regulating the rotation direction and the rotation angle of the satellite antenna according to the change of the DC level signal. The invention adopts the polarized tracking principle identical to the pitching tracking mode to realize the tracking of the angle closed loop and then the tracking of the signal closed loop, reduces the double-direction interference problem of the reversed polarized signal and improves the communication quality.

Owner:北京西鼎众合技术有限公司

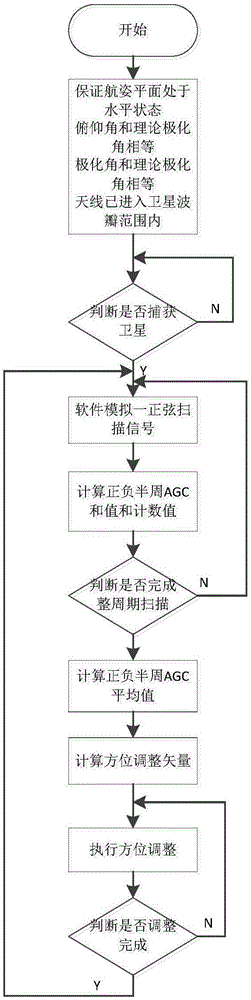

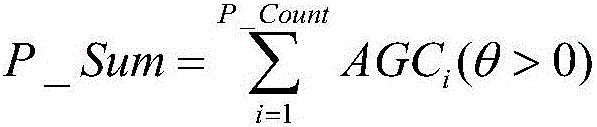

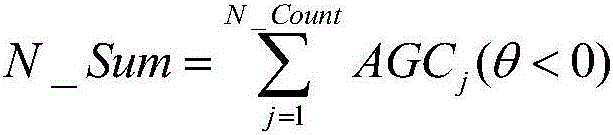

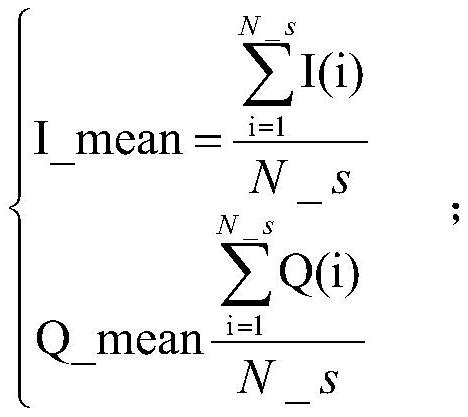

Movable type VSAT antenna tracking method

The invention provides a movable type VSAT antenna tracking method. In the antenna beam range, by means of a sine wave scanning mode, the orientation adjusting direction and size are determined according to the size relation of positive and negative half-cycle AGC level mean values. When the antenna electrical boresight is aligned with the center of the lobe, the difference of the positive and negative half-cycle AGC level mean values is approximately zero to be taken as the basis for aligning with a satellite. No additional hardware circuit needs to be added on the basis of the original stepping tracking hardware, the cost is low, and the method is simple and easy to realize, and the random interference can be effectively eliminated by the error signal obtained by the difference of the positive and negative half-cycle AGC level mean values in the same frequency and phase of the scanning frequency. According to the invention, the tracking error size and direction can be directly solved, and the misoperation of a system is reduced.

Owner:西安坤蓝电子技术有限公司

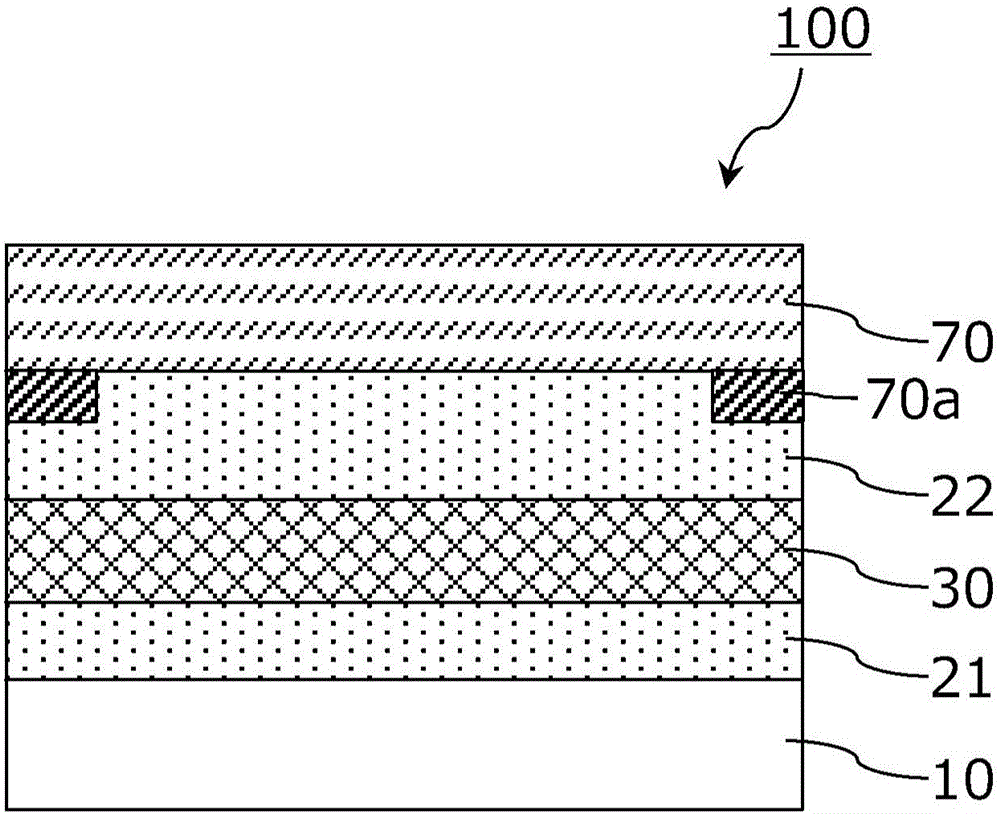

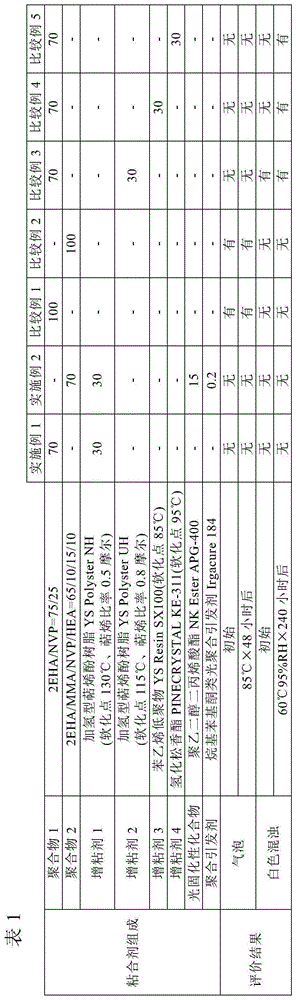

Tackifying agent and image display device using this adhesive

ActiveCN105073935AEasy to operateHas height difference followabilityFilm/foil adhesivesEster polymer adhesivesPolymer scienceAdhesive

The tackifying agent of the present invention contains an acrylic base polymer and a hydrolyzable terpene phenol resin with a softening point of 70°C to 150°C. The hydrolyzable terpene phenol resin preferably has a terpene molar ratio of 0.1 to 0.7. The amount of acrylic base polymer is preferably 45 to 95 weight parts in 100 weight parts of the total amount of the tackifying agent composition. Furthermore, the total amount of the acrylic base polymer and the hydrolyzable terpene phenol resin is preferably 14 weight parts or more. The tackifying agent of the present invention does not easily become cloudy even under high temperature high humidity conditions, and has step tracking properties, and therefore can be used by placing between a front surface transparent plate and a touch panel, between a front surface transparent plate and an image display panel, or between a touch panel and an image display panel.

Owner:NITTO DENKO CORP

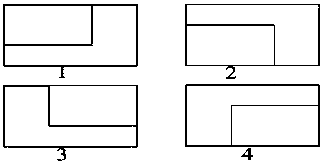

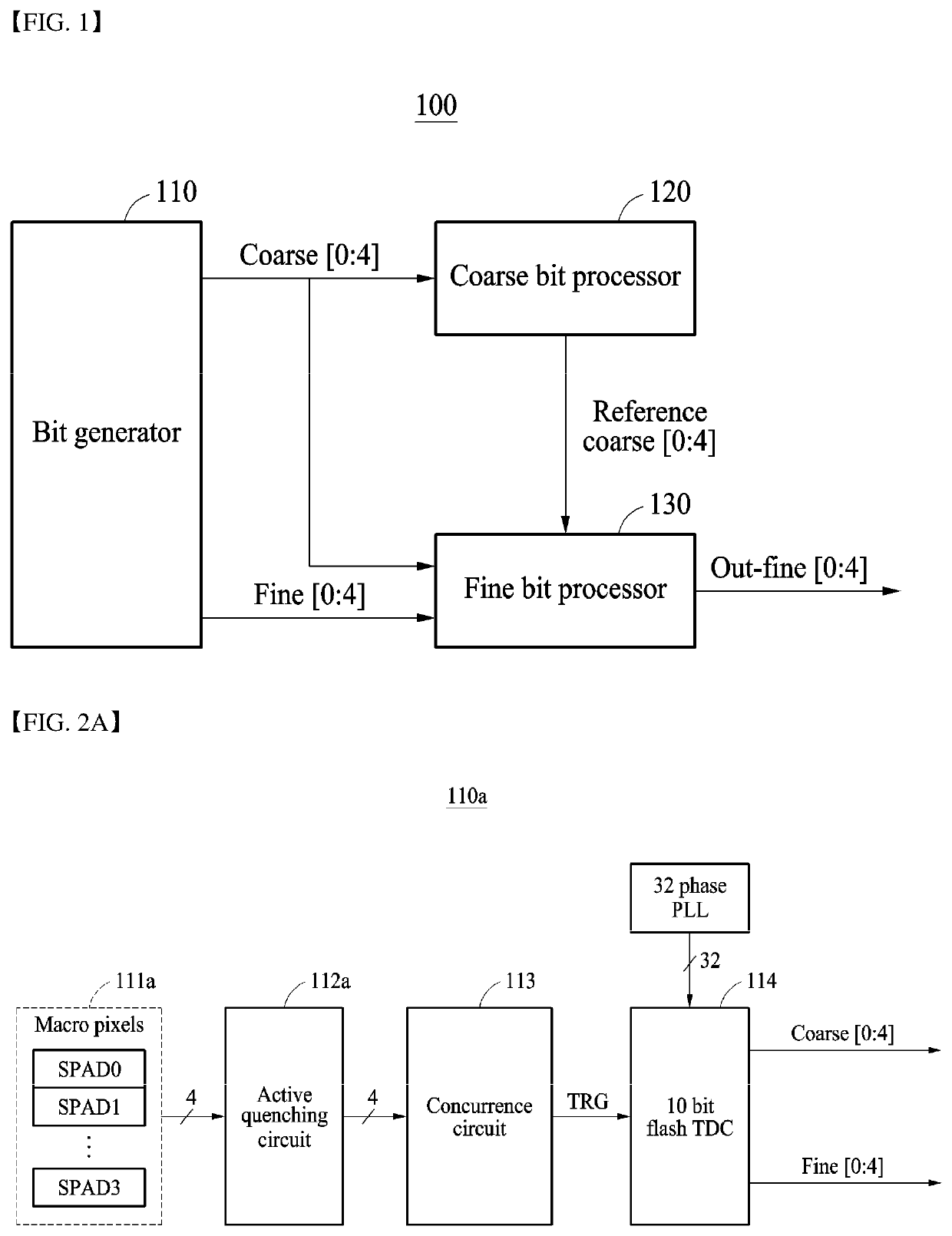

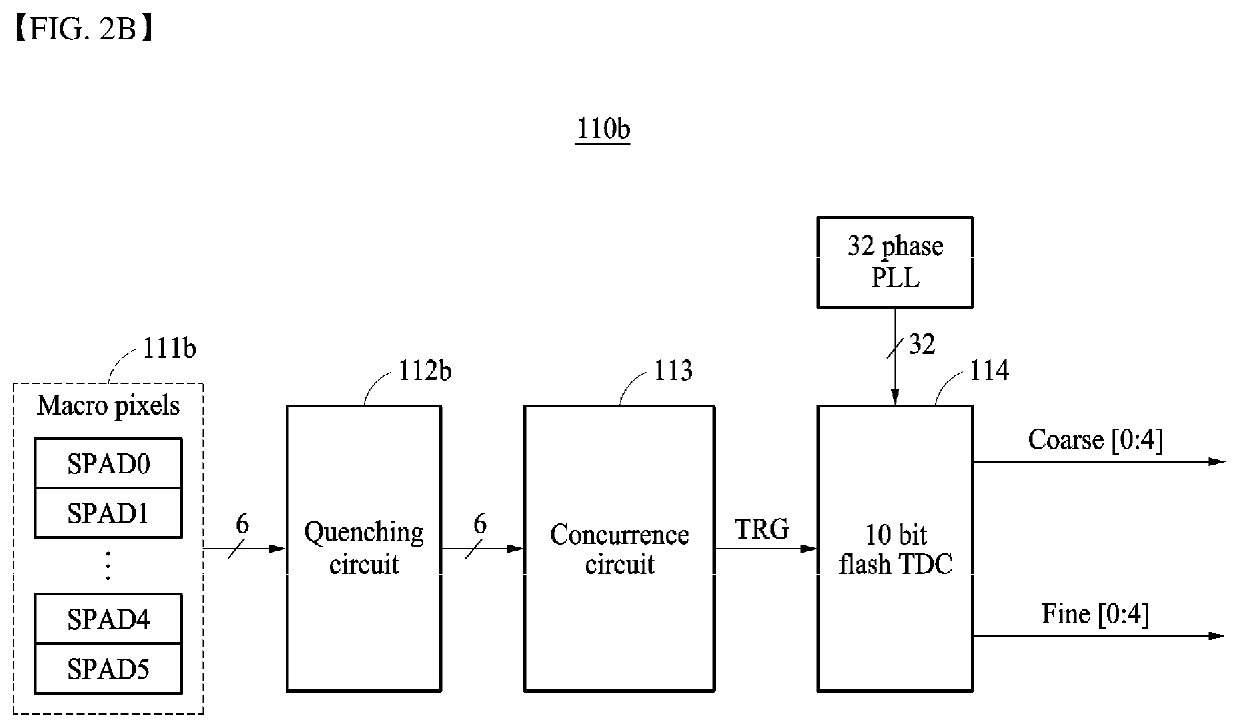

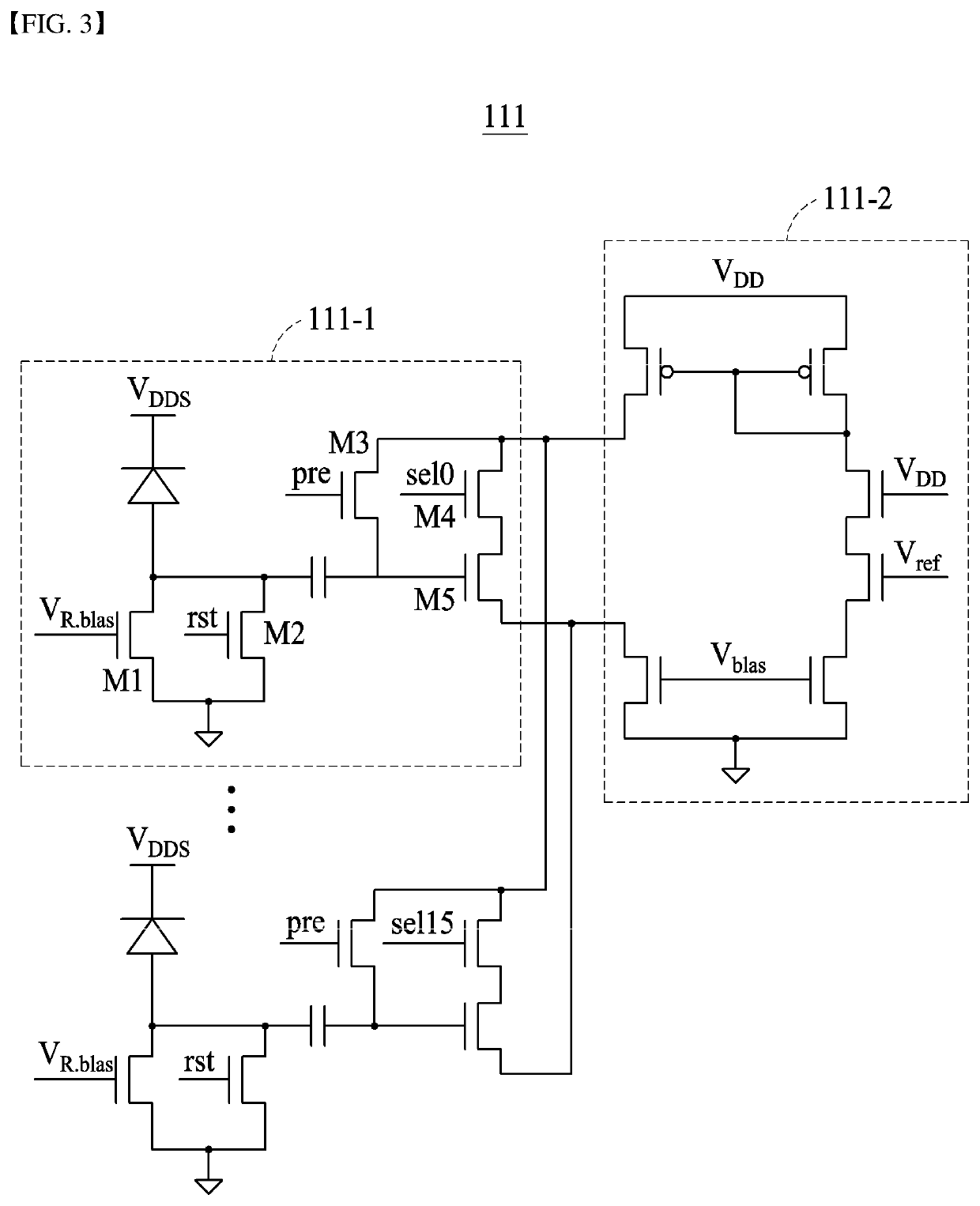

Apparatus for measuring distance using two-step tracking based on SPAD sensor and method thereof

ActiveUS10746543B2Reduce capacityReduce areaOptical rangefindersElectromagnetic wave reradiationComputer hardwareSensing data

Disclosed are an apparatus for measuring distance using two-step tracking and a method thereof. More particularly, the apparatus includes a bit generator configured to generate coarse bits for first tracking from sensing data to measure distance to a target and fine bits for second tracking, corresponding to the coarse bits, to measure precise distance to the target; a coarse bit processor configured to receive the coarse bits, address the received coarse bits in any one histogram bin, which corresponds to the received coarse bits, among a plurality of histogram bins, and output coarse bits, which correspond to any one histogram bin exceeding a preset threshold among the histogram bins, as reference coarse bits; and a fine bit processor configured to output fine bits corresponding to the reference coarse bits.

Owner:IND ACADEMIC COOP FOUND YONSEI UNIV

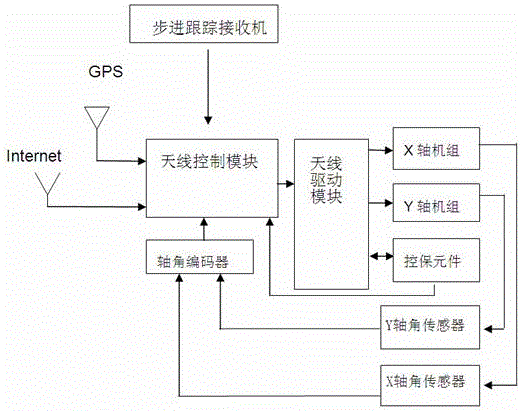

Automatic reception and control system for forest fire monitoring

InactiveCN106373316ASolve real-time receive processingImproved ability to track targetsForest fire alarmsControl systemEngineering

The invention discloses an automatic reception and control system for forest fire monitoring. The system comprises a step tracking receiver, an antenna control module, an antenna driving module, a shaft angle encoder and an execution module arranged on an antenna pedestal. The output of the step tracking receiver is connected with the antenna control module; the output of the antenna control module is connected with the antenna driving module; the output of the antenna driving module is connected with the execution module; the output of the execution module is connected with the shaft angle encoder; the output of the shaft angle encoder is connected with the antenna control module; and the shaft angle encoder processes the captured signals and then, transmits the signals to the antenna control module, and is used for position display and position control of the antenna. The system has the advantages of being good in monitoring timeliness, reliable and high in precision, and improving target tracking capability of the antenna.

Owner:天立泰科技股份有限公司

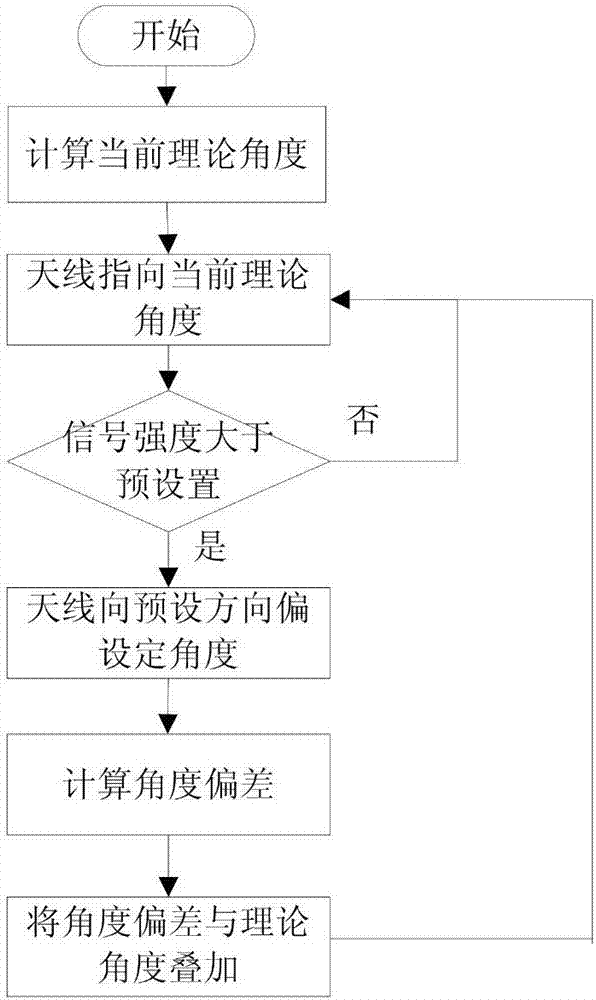

Composite tracking method for airborne satellite communication antenna

InactiveCN106911000AEasy to implementLow costAntenna adaptation in movable bodiesSatellite trackingCommunication link

The invention discloses a compound tracking method for an airborne satellite communication antenna. It calculates the theoretical angle of aiming at the target according to the GPS and inertial navigation data provided by the outside, and then adopts the compound tracking method of guiding and superimposing steps to obtain the angle deviation that needs to be corrected, and the superposition needs to be corrected on the basis of the calculated theoretical angle The angular deviation of the antenna can realize the real-time tracking of the satellite. It avoids the problem that the single digital guidance tracking will cause the antenna to fail to follow the maximum point of the signal due to inertial navigation drift, calibration errors, etc., thereby improving the tracking accuracy of the servo and ensuring the stability of the communication link.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

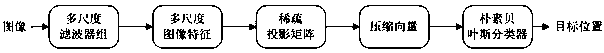

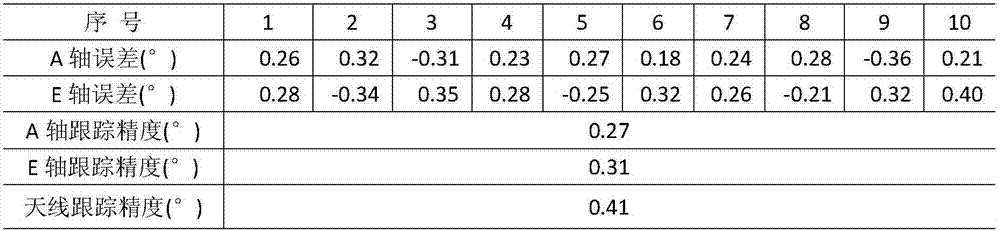

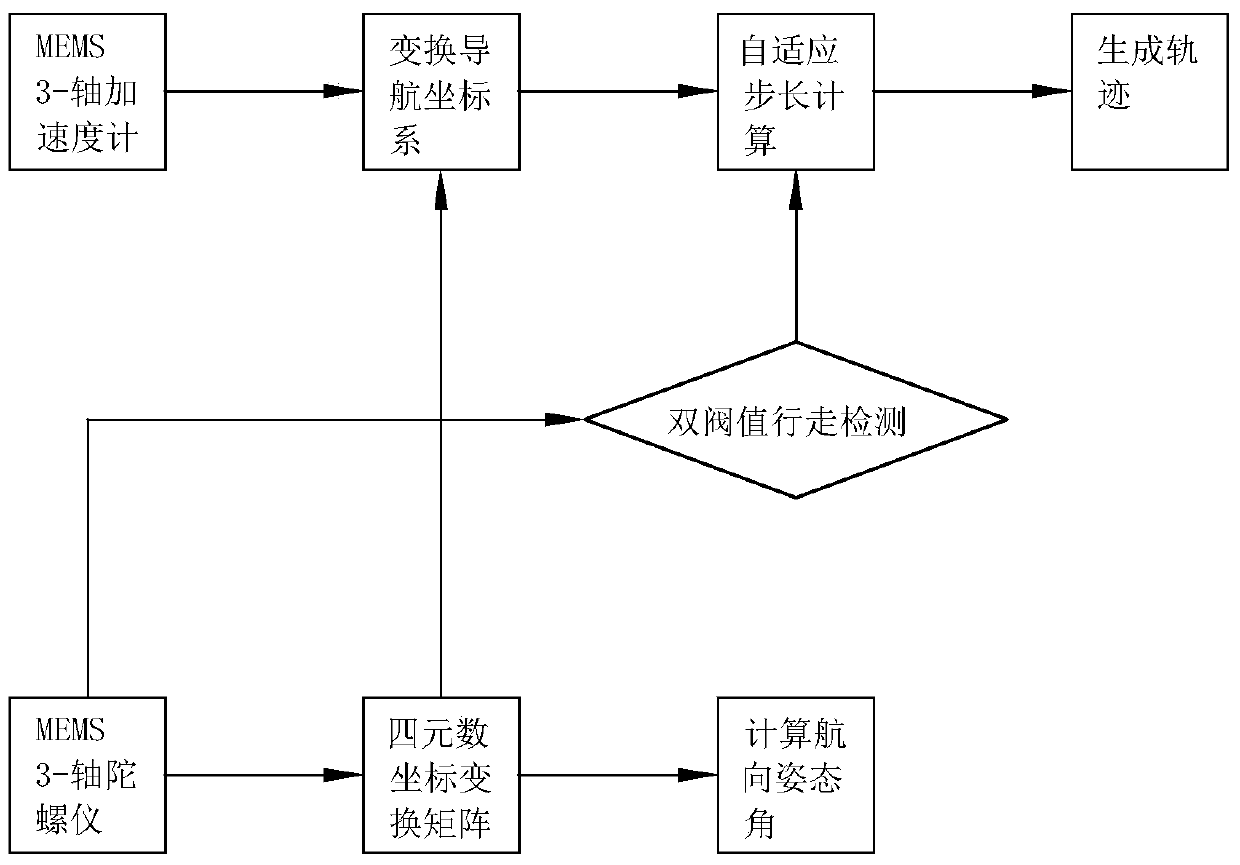

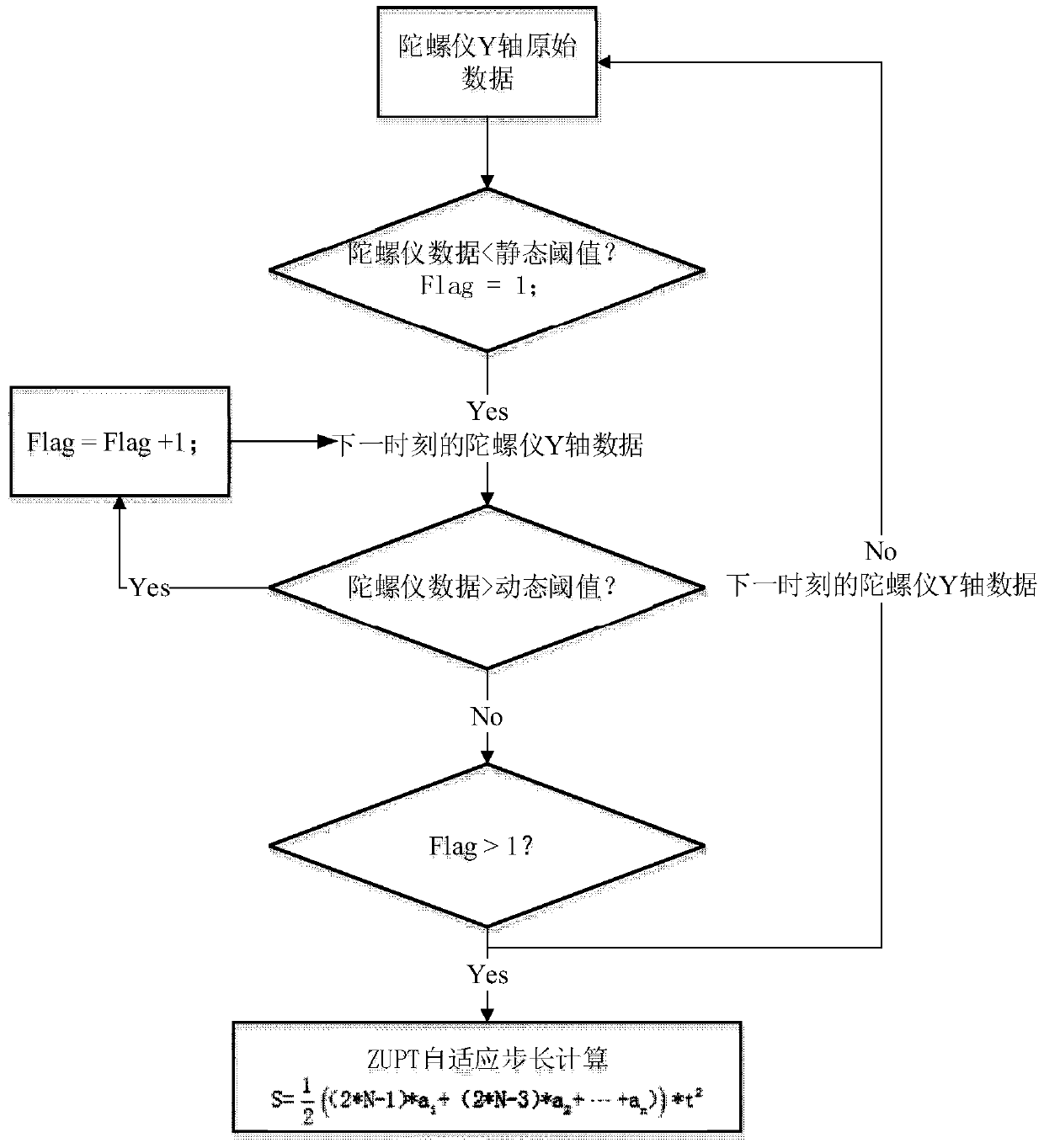

An Indoor Trajectory Tracking Method with Adaptive Step Size

InactiveCN104634345BHigh precisionReduce step size calculation errorNavigation by speed/acceleration measurementsSimulationCalculation error

The invention relates to an indoor trajectory tracking method with self-adaptive step length. The indoor trajectory tracking method comprises the following steps: setting the initial speed and the final speed of every step of walking are zero, judging whether to be in a walking state, if so, collecting the number of accelerations in every step, and calculating to obtain the step length of the first step according to the accelerations and the sampling time of the accelerations; by combining with the direction of every step, carrying out vector superposition on every step, and thus obtaining the motion trajectory. The indoor trajectory tracking method has the advantages that by adoption of indoor-pedestrian trajectory tracking based on an MEMS inertial sensor, the accuracy of gesture detection of an inertial navigation positioning system is improved and the errors of the step-length calculation are reduced, so that the accuracy of navigation positioning is improved; and by adoption of the self-adaptive mechanism, the step length of every step can be accurately calculated, the accuracy of navigation positioning can be improved and the promotion of inertial navigation positioning application can be enhanced.

Owner:HUAQIAO UNIVERSITY +1

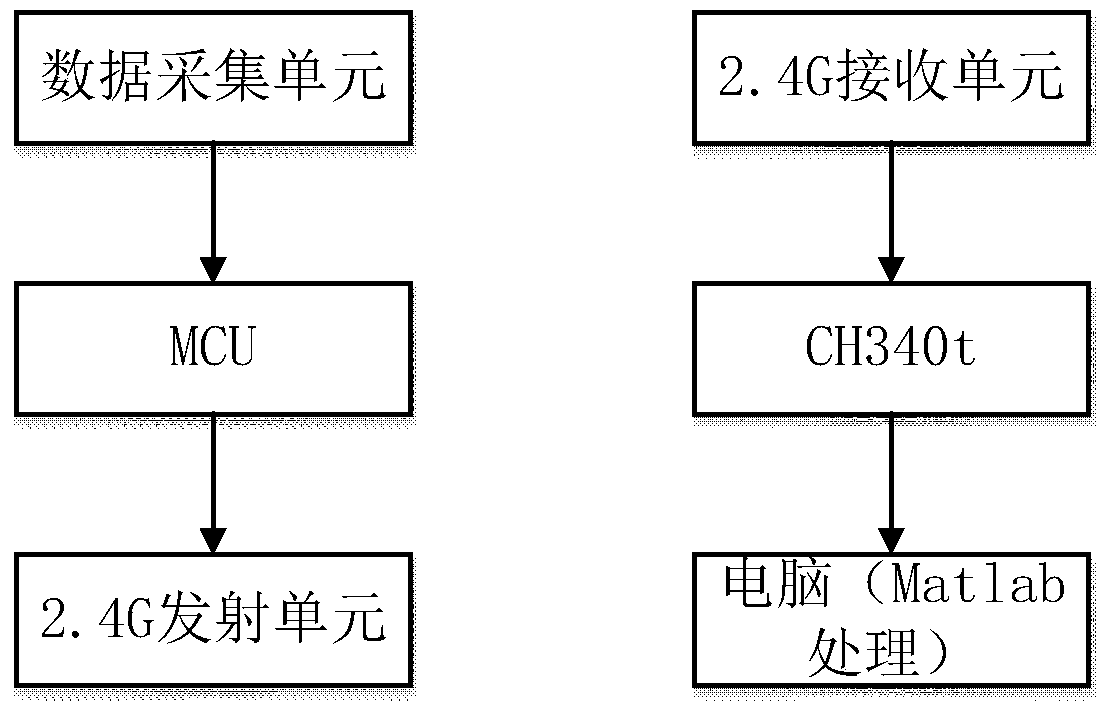

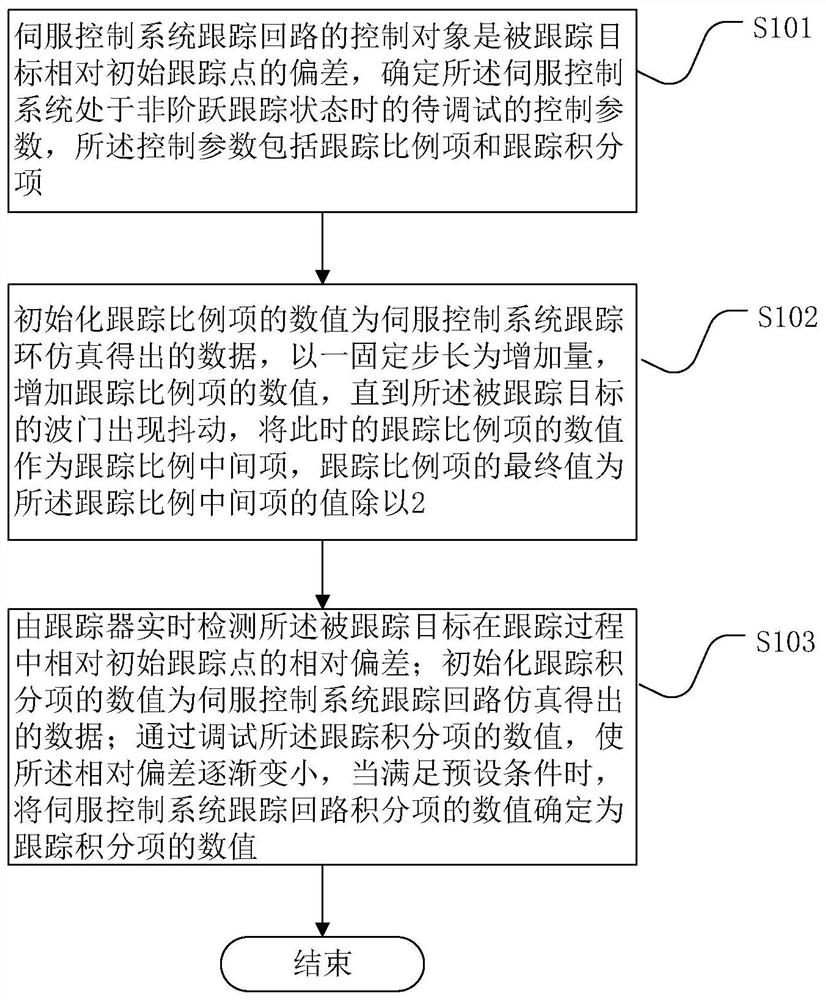

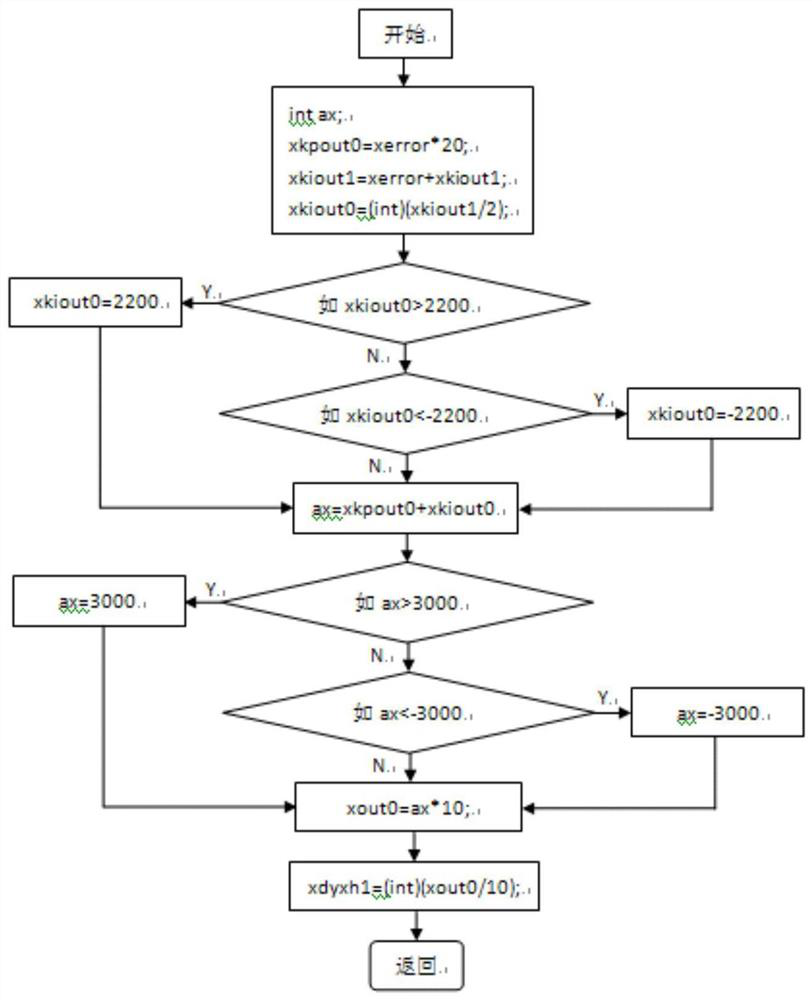

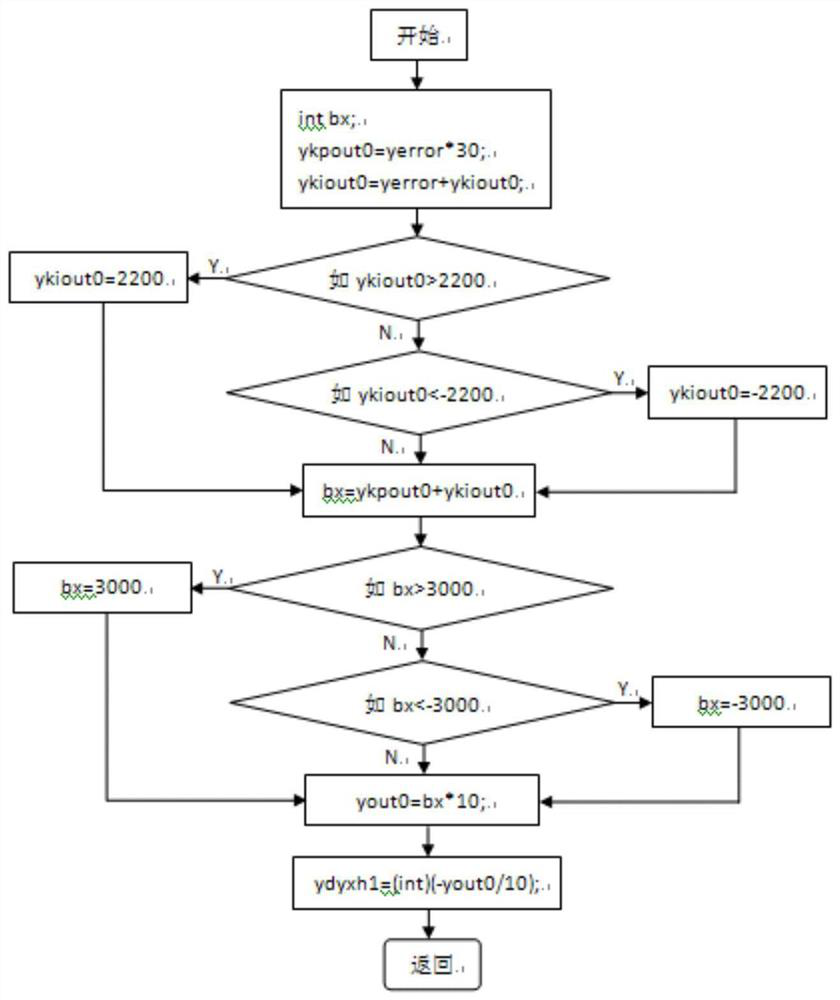

Method and device for debugging control parameters of servo control system in non-step tracking state

PendingCN114115132AImprove accuracyHigh debugging accuracyNumerical controlTotal factory controlControl systemControl engineering

The invention provides a control parameter debugging method and device for a servo control system in a non-step tracking state. The method comprises the following steps: determining a to-be-debugged control parameter when the servo control system is in the non-step tracking state; initializing a numerical value of a tracking proportional item as data obtained by tracking loop simulation of the servo control system, increasing the numerical value of the tracking proportional item until a wave gate of the tracked target shakes, and taking the numerical value of the tracking proportional item at the moment as a tracking proportional intermediate item; the relative deviation is gradually reduced by debugging the numerical value of the tracking integral item, and when a preset condition is met, the numerical value of the tracking loop integral item of the servo control system is determined as the numerical value of the tracking integral item. The method shortens the debugging time of the tracking loop, improves the debugging precision of the tracking loop, reduces the debugging workload, and is of great significance to batch production of the servo stabilized platform.

Owner:HEBEI HANGUANG HEAVY IND

Method and system for seeking stars by using satellite antenna

The invention discloses a method and a device for seeking stars by using a satellite antenna. The method comprises the steps of: S1, judging that the antenna is in an unfolded state or a folded state; S2, if the antenna is in the folded state, controlling a main reflecting surface of a pitching motor driving antenna and a feed source supporting rod to be lifted to the preset positions by using a control system, installing side lobes and carrying out the step S3; if the antenna is in the unfolded state, directly carrying out the step S3; S3, reading the data of an inclinometer and calculating the pitching state of the antenna according to the data by using the control system; S4, initializing the direction state of the antenna by using the control system; S5, rotating the main reflecting surface of the antenna to the working position by using the control system; and S6, carrying out satellite search and step tracking by using the control system. The invention achieves the purpose of accurate star seeking by adopting the control system for control the polarization, the direction and the pitching of the satellite antenna and solves the problems of complicated operation, instable performance and low star-matching speed of the satellite antenna in the prior art.

Owner:AKD COMM TECH

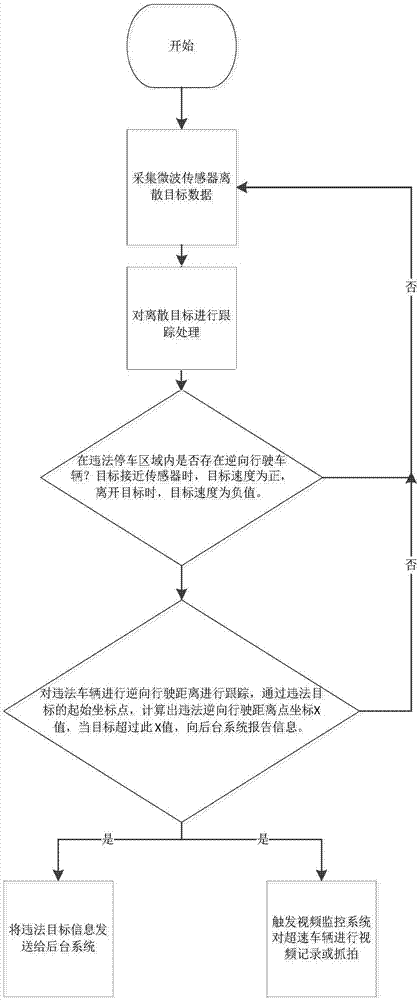

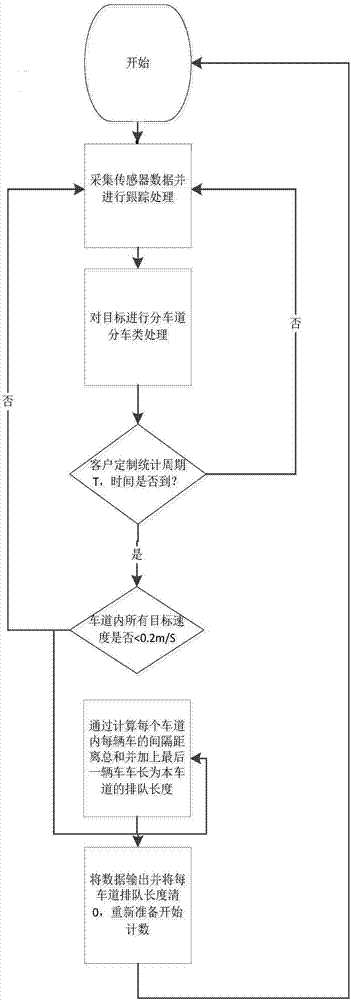

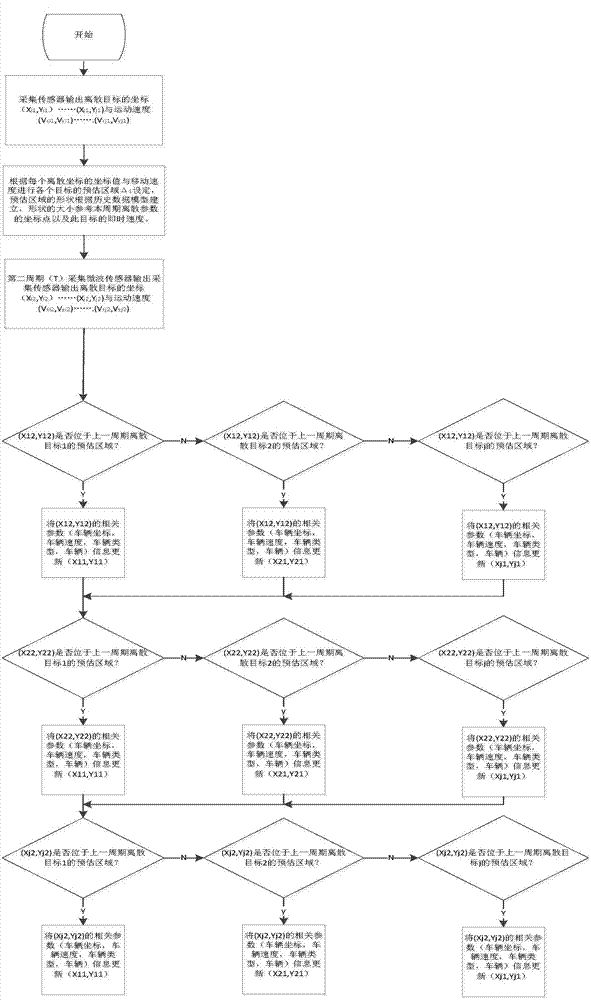

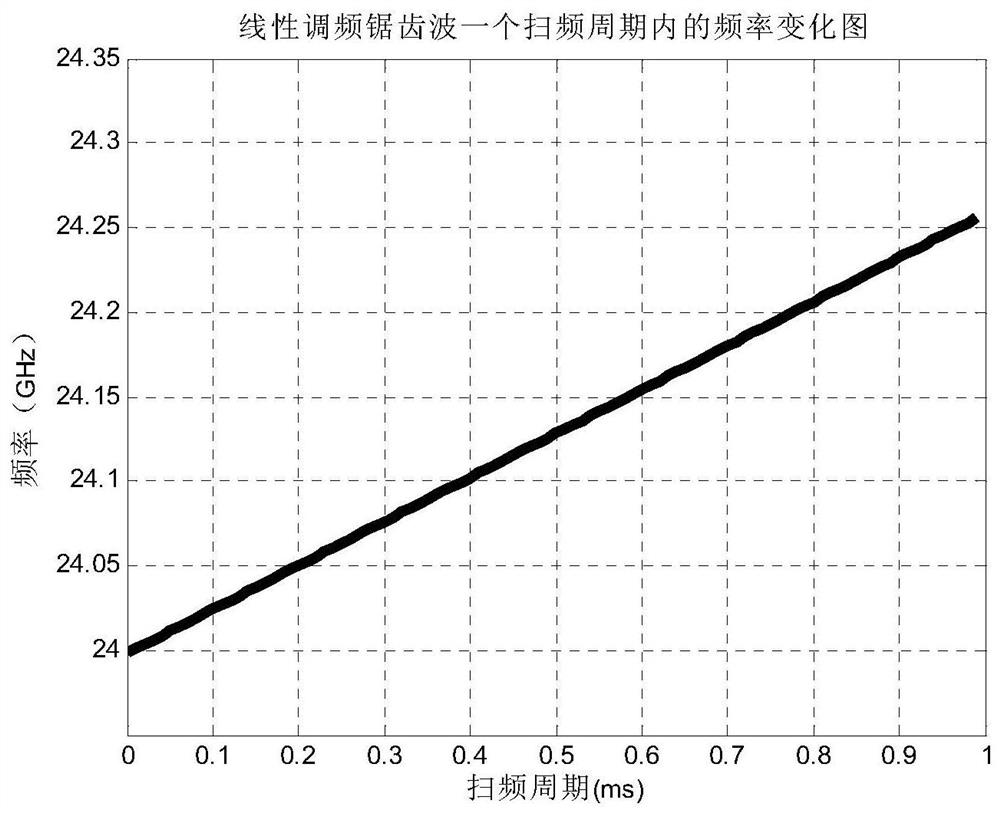

Microwave-based Intelligent Traffic Behavior Perception Method and System

The invention provides a microwave-based intelligent traffic behavior perception method and system. The intelligent traffic behavior perception method includes: a traffic parameter setting step, a road traffic background learning step, a road background noise suppression step, a calculation step, a coordinate system establishment step, The vehicle type classification step, the tracking processing step, and the triggering alarm step. The beneficial effects of the present invention are: the present invention proposes a microwave (millimeter wave)-based system that can operate around the clock, has high precision, high reliability, large-area detection, high economic benefit and cost ratio, easy installation, and multi-dimensional A method and system for comprehensive traffic behavior analysis of various vehicles in the detection area. At the same time, background noise suppression is performed through a two-dimensional radar image method for some road barriers such as isolation belts or metal railings that will affect radar performance.

Owner:NANJING HURYS INTELLIGENT TECH CO LTD

Satellite antenna polarization closed-loop tracking method and device

ActiveCN105337039BReduces two-way interference issuesImprove communication qualityAntennasLoop closingCommunication quality

The invention discloses a satellite antenna polarized closed loop tracking method and a device. The satellite antenna polarized closed loop tracking method comprises steps performing angle loop closing on a pitch angle, an azimuth and a polarized angle of the satellite antenna, regulating the pitch angle, the azimuth and the polarized angle to a first preset angle, a second preset angle and a third preset angle, performing polarized stepping tracking on a beacon signal of a satellite according to a beacon signal frequency, converting the beacon signal to a DC level signal according to the regulated pitch angle, the azimuth and the polarized angle, and regulating the rotation direction and the rotation angle of the satellite antenna according to the change of the DC level signal. The invention adopts the polarized tracking principle identical to the pitching tracking mode to realize the tracking of the angle closed loop and then the tracking of the signal closed loop, reduces the double-direction interference problem of the reversed polarized signal and improves the communication quality.

Owner:北京西鼎众合技术有限公司

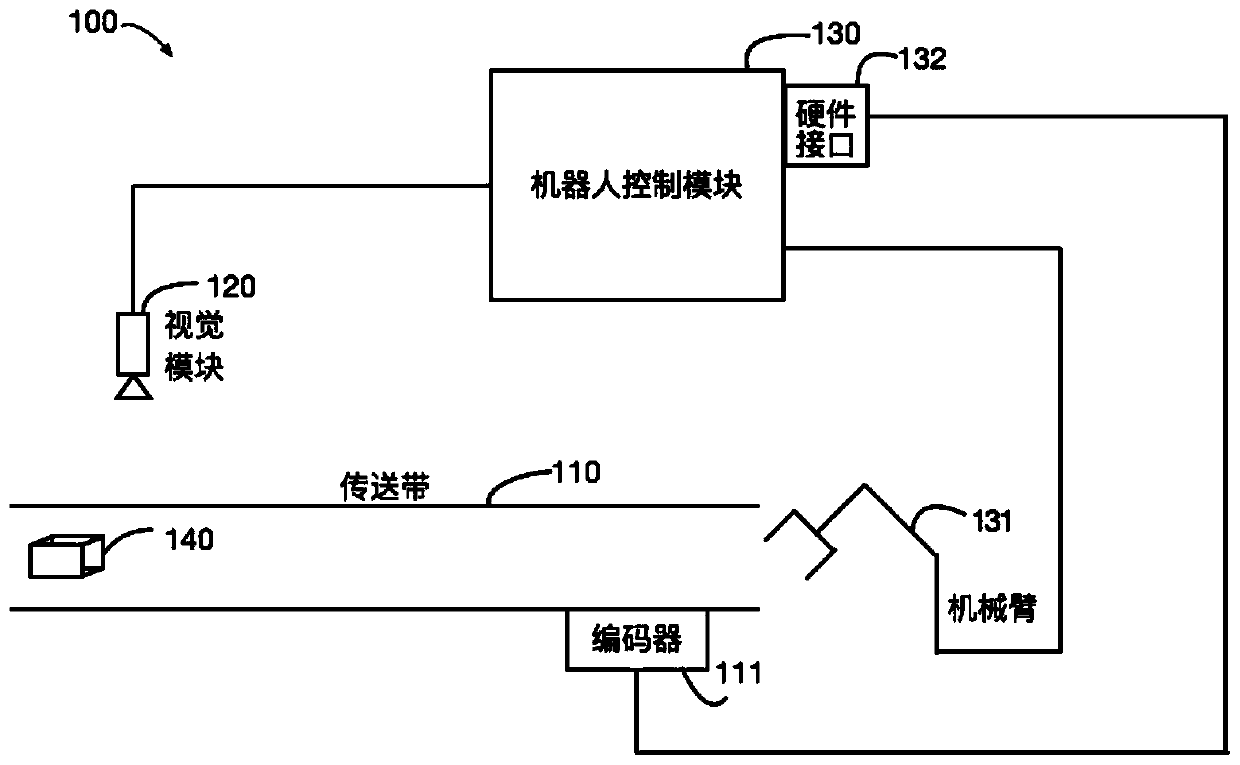

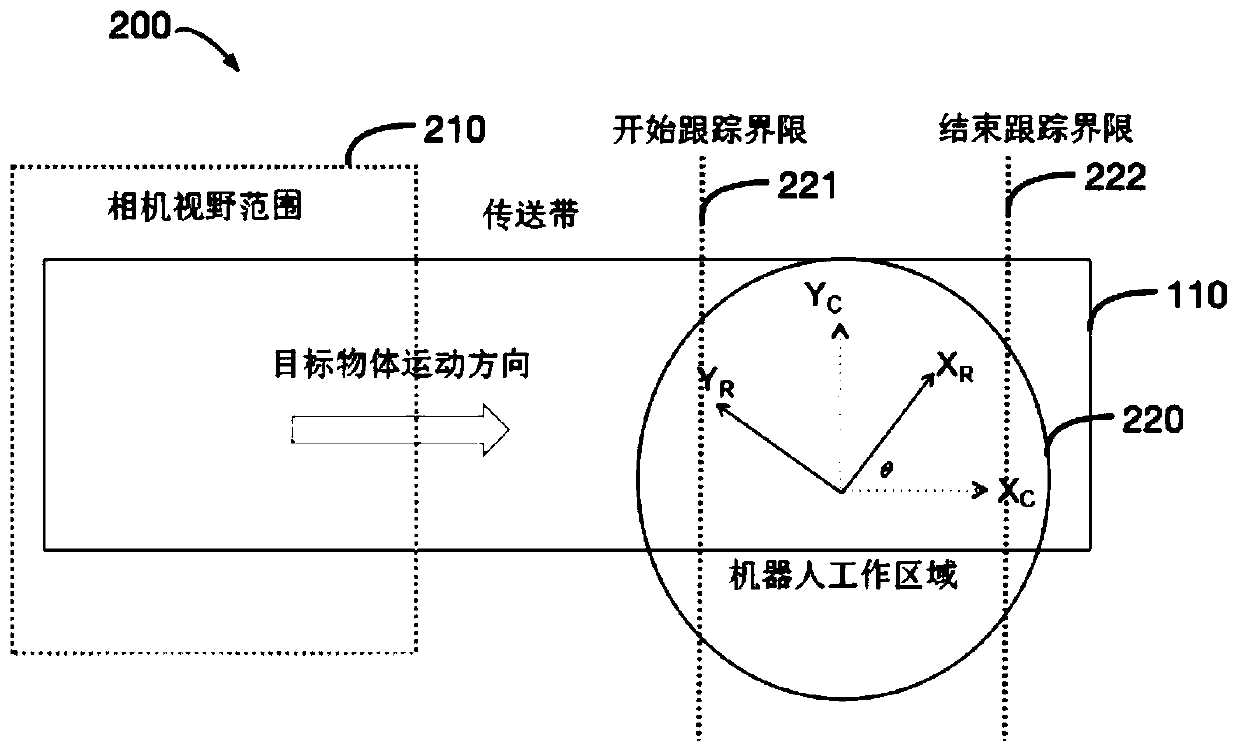

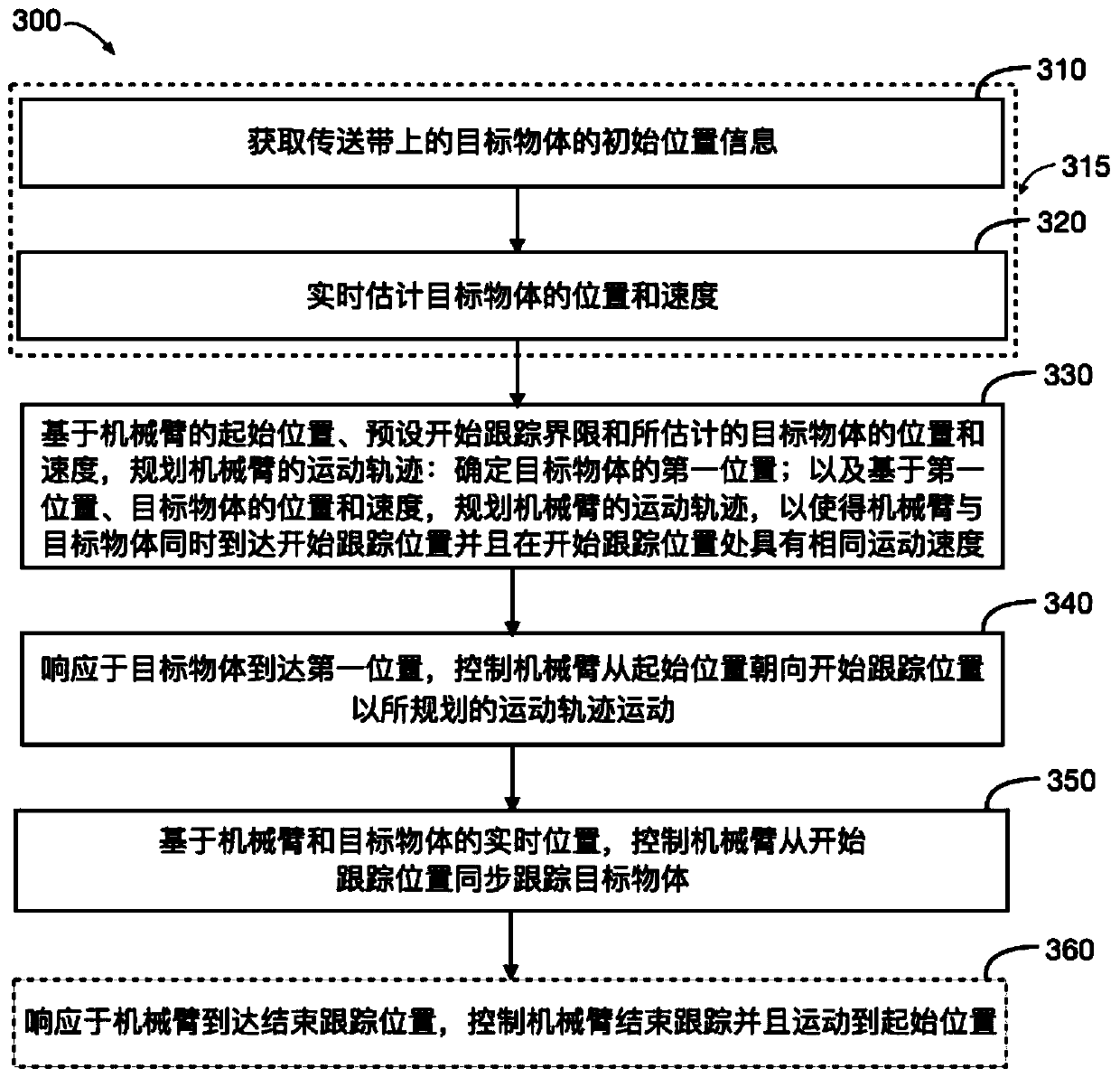

A conveyor belt synchronous tracking method, device and system for robots

ActiveCN108674922BAchieve positioningImplement trackingProgramme-controlled manipulatorConveyorsIndustrial systemsSimulation

The invention relates to a conveyor belt synchronous tracking method, device and system for a robot. The method comprises the following steps that initial position information of a target object on aconveyor belt is acquired, and the position and speed of the target object are estimated in real time; based on the start position of the robot, the preset start tracking limit and the estimated position and speed of the target object, the motion trajectory of the robot is planned so that when the target object reaches the first position, the robot can move from the start position to the start tracking position at the same time as the target object and have the same motion speed as the target object at the start tracking position; the robot is controlled to move in the planned motion trajectory in response to the target object reaching the first position; and based on the real-time positions of the robot and the target object, the robot is controlled to synchronously track the target object from the starting tracking position. By the adoption of the conveyor belt synchronous tracking method, device and system for the robot, fast target object positioning and tracking can be realized, the speed fluctuation is reduced, and the accuracy and work efficiency of an industrial system are improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Peak Tracking Method of UAV Altitude Signal

ActiveCN107783102BShorten operation timeImprove real-time performanceRadio wave reradiation/reflectionRadarPoint tracking

Owner:DALIAN ROILAND SCI & TECH CO LTD

Satellite tracking antenna system and method therefor

The present invention relates to a satellite tracking antenna system and a satellite tracking method. Step tracking in which the size of a satellite signal sampled in at least one position in which a reflector of the satellite tracking antenna system is tilted is compared to track a satellite is performed, and a measured value of the satellite signal sampled in a specific position in which the reflector is tilted in N-lth tracking and a measured value of the satellite signal sampled in the specific position in which the reflector is tilted in Nth tracking are averaged to compute a value. The reflector is driven according to the value to track the satellite, thereby minimizing a satellite tracking error caused by a sudden movement of a mobile body equipped with the satellite tracking antenna system.

Owner:INTELLIAN TECH

A multifunctional machine for glass cutting, coding, engraving and thickness measurement

The invention provides a multifunctional machine for glass cutting, code-spurting, carving and thickness measurement and relates to the field of glass machinery. The multifunctional machine comprises a worktable top of the machine; the multifunctional machine is characterized in that longitudinal traveling mechanisms are arranged on the two sides of the worktable top, a cross beam is erected between the longitudinal traveling mechanisms on the two sides, a transverse traveling drive mechanism is arranged on the transverse beam, and a multifunctional handpiece is arranged on the transverse traveling drive mechanism and comprises a code-spurting mechanism, a precision cutter box, a thickness measurement mechanism and a traveling power transmission mechanism. The multifunctional machine for glass cutting, code-spurting, carving and thickness measurement is a multifunctional glass machining machine and has the functions of cutting, code-spurting, carving and thickness measurement simultaneously; a glass cutter or a carving cutter can be mounted in the precision cutter box and can be used for cutting and carving glass; the code-spurting mechanism is capable of realizing spray printing of the content needed by a customer on plate glass and used for step tracking and workpiece identification.

Owner:ANHUI YINRUI GLASS MACHINERY

Scale Adaptive Target Tracking Method Based on Fast Compressive Tracking Algorithm

ActiveCN108062557BReduce processing timeEnhanced Representational CapabilitiesCharacter and pattern recognitionClosed circuit television systemsPattern recognitionContext model

The invention discloses a scale adaptive target tracking method based on a fast compression tracking algorithm. Firstly, the present invention adopts the context model to weight the Haar-like features, which enhances the robustness of the Haar-like features to illumination changes. Secondly, the step-by-step tracking is adopted, which not only enhances the anti-occlusion ability of the algorithm and the ability to deal with the change of target scale, but also maintains the real-time performance of the algorithm. Finally, a scale-adaptive method is proposed to achieve stable tracking of scale-varying targets. The present invention has good robustness to the change of the target scale, the change of the target appearance and the situation that the target is blocked, and can guarantee the frame rate at about 39 frames per second, which meets the requirement of real-time performance.

Owner:青岛青咨工程咨询有限公司

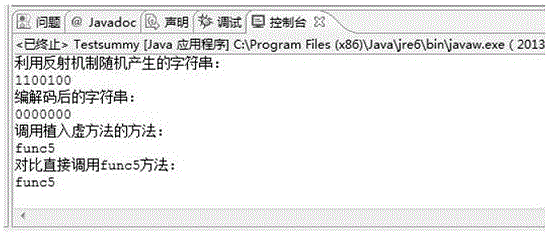

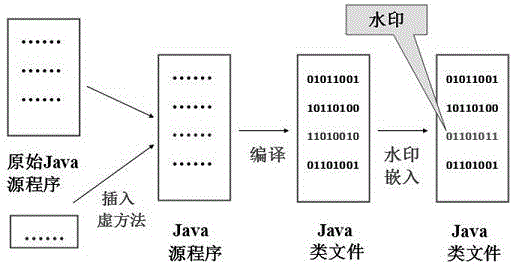

A permanent false construction method of java software watermark implanted virtual method

ActiveCN103714271BStructural damageResist attackProgram/content distribution protectionAlgorithmJava

A Java software watermark embedding virtual method permanent false construction method, including invoking data with common characteristics in the software; encoding each of the data, and setting the encoding to make the calculated constant value is zero and used as the value of the permanent false. The beneficial effects of the present invention are: the organic combination of Java reflection mechanism, dynamic random generation of 0 and 1 strings, positive and negative code encoding and decoding, etc., so that the virtual method constructed by the present invention has good concealment and is not easy to be detected. At the same time, it can effectively resist a variety of common attacks against software watermarks, including semantic transformation attacks, statistical attacks, code addition and deletion attacks, and single-step tracking and debugging attacks.

Owner:南通大学技术转移中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com