Method and device for debugging control parameters of servo control system in non-step tracking state

A technology of servo control system and control parameters, which is applied in the field of servo system control, can solve problems such as unclear control algorithm, poor system stability, and no rules for parameter debugging, so as to reduce debugging workload, improve accuracy, and shorten debugging time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

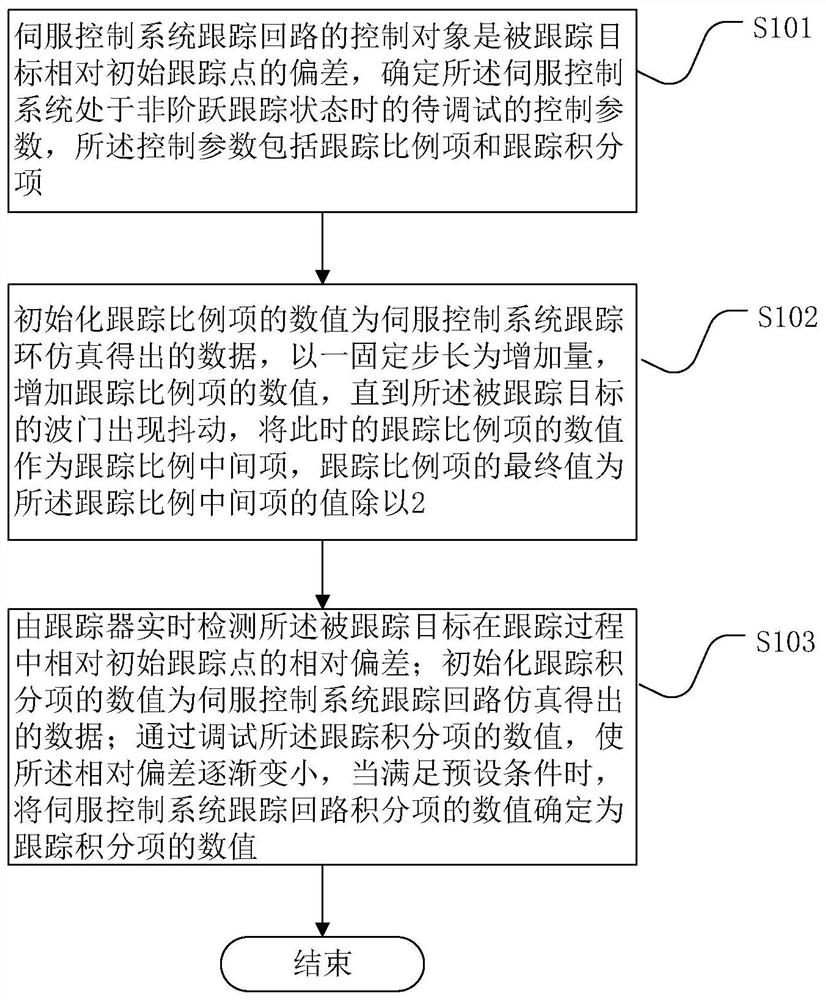

[0028] combine first Figure 1-3 The process flow of a method for debugging control parameters of a servo control system in a non-step tracking state according to an embodiment of the present invention is described. The method includes the following steps:

[0029] Step S101: The control object of the tracking loop of the servo control system is the deviation of the tracked target relative to the initial tracking point, and determine the control parameters to be debugged when the servo control system is in the non-step tracking state, and the control parameters include tracking proportional items and track credit items;

[0030] Step S102: Initialize the value of the tracking proportional item as the data obtained from the simulation of the tracking loop of the servo control system, increase the value of the tracking proportional item with a fixed step size until the wave gate of the tracked target shakes, and the The numerical value of the tracking ratio item at this moment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com