Tackifying agent and image display device using this adhesive

An image display panel and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as easy generation of air bubbles, and achieve height difference followability , Excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

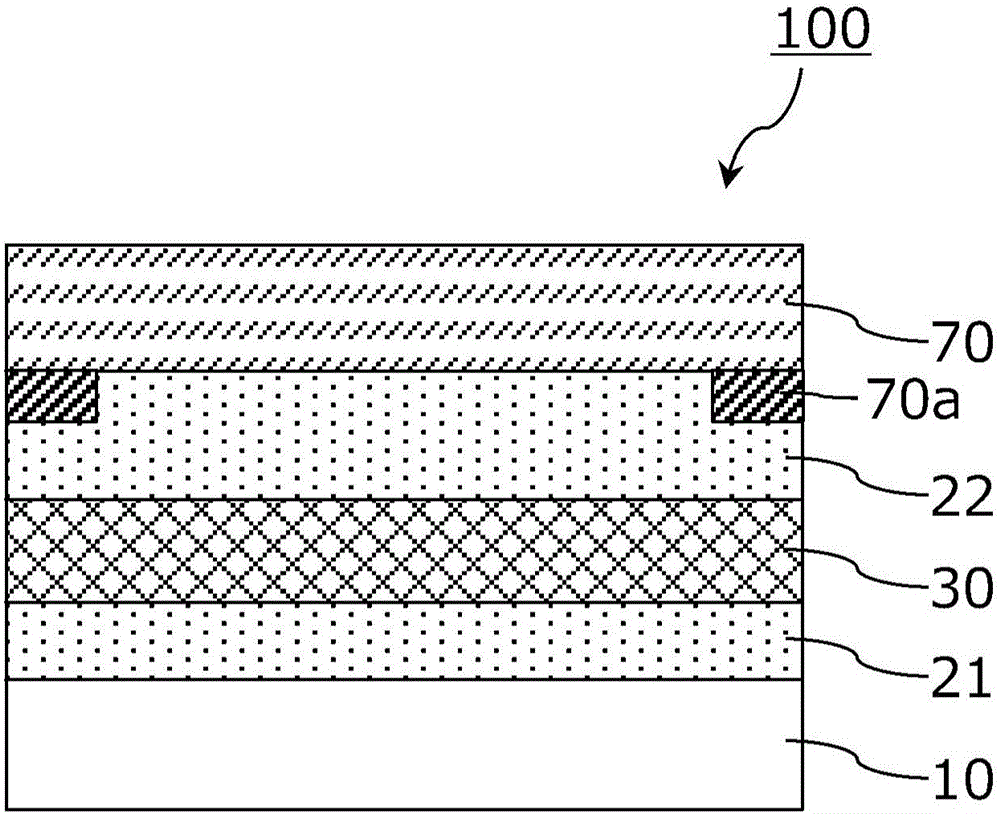

Image

Examples

preparation example Construction

[0036] When preparing the above-mentioned acrylic polymer, a polymerization initiator such as a photopolymerization initiator (photoinitiator) or a thermal polymerization initiator can be used depending on the type of polymerization reaction. The polymerization initiators may be used alone or in combination of two or more. The usage-amount of a photoinitiator is not specifically limited, For example, 0.01-0.5 weight part is preferable with respect to 100 weight part of total monomer components which form an acrylic base polymer, More preferably, it is 0.05-0.3 weight part.

[0037] The molecular weight of the base polymer can be appropriately adjusted. For example, the weight average molecular weight in terms of polystyrene is about 50,000 to about 2 million, preferably about 70,000 to about 1.8 million.

[0038] In the pressure-sensitive adhesive of the present invention, the above-mentioned base polymer may have a cross-linked structure as necessary. Formation of a crosslin...

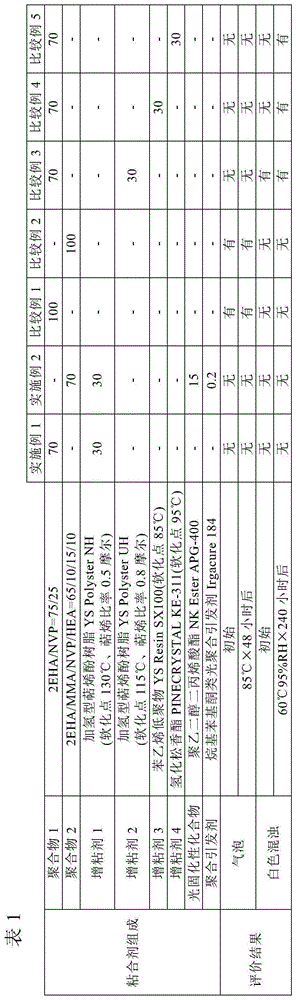

Embodiment

[0067] Examples and comparative examples are given below for further description, but the present invention is not limited to these examples.

Synthetic example 1

[0070] 2-ethylhexyl acrylate (2EHA) of 75 parts by weight, N-vinylpyrrolidone (NVP) of 25 parts by weight, 0.2 Parts by weight of azobisisobutyronitrile (AIBN) as a polymerization initiator and 233 parts by weight of ethyl acetate were passed through with nitrogen, and nitrogen replacement was performed for about 1 hour while stirring. Then, the flask was heated to 70° C. and reacted for 5 hours to obtain an acrylic polymer having a weight average molecular weight (Mw) of 800,000 (hereinafter, this base polymer is referred to as “polymer 1”).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com