Method for reducing uncertainty of steam turbine performance test

A certainty, steam turbine technology, applied in engine testing, machine/structural component testing, instruments, etc., can solve problems such as increased uncertainty in steam turbine performance tests, internal leakage of valves, increased diameter of accidental drainage pipes, etc., to achieve reduction The Effect of Performance Test Uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A method for reducing the uncertainty of the steam turbine performance test of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0034] Such as figure 1 Shown according to the typical ultra-supercritical steam turbine performance examination test measuring point arrangement diagram designed according to the present invention, comprises the following steps:

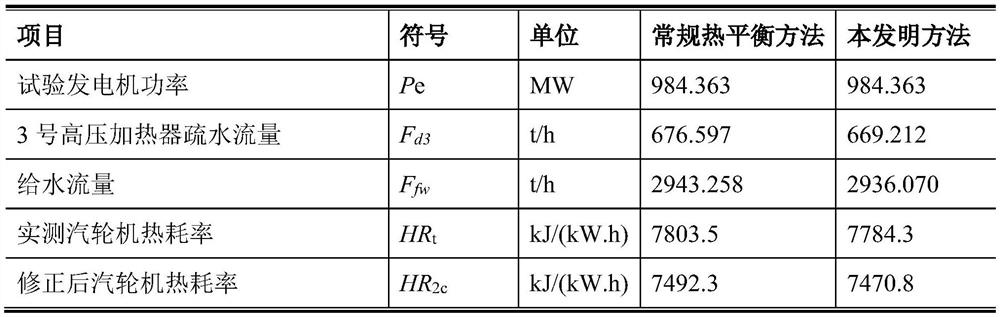

[0035] A kind of method that the invention provides to reduce the uncertainty of steam turbine performance test, such as figure 1 As mentioned, in the 1st stage high pressure heater ( figure 1 In the example above, it is the No. 3 high-pressure heater) The flow measurement device 1 recommended by the installation procedure "ISO 5167-2003, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full" on the drain pipe, and the flow Pressure measuring point 4 is installed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com