On-line measurement method for micro-waviness of advanced glass substrate

A technology of glass substrates and measurement methods, which is applied in the direction of measurement devices, preparation of test samples, and material analysis through optical means. It can solve the problems of not being able to sample too much glass, long testing time, and unknown micro-waviness of the entire board, etc. problem, to achieve the effect of sample improvement, precision and accuracy, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

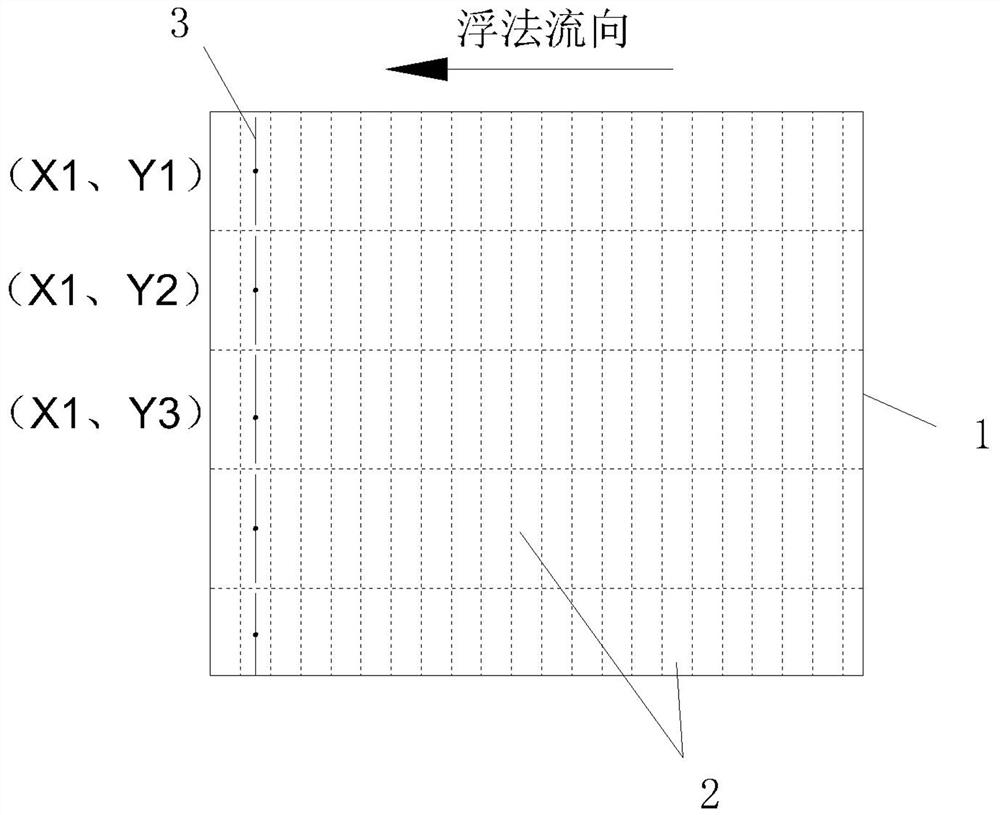

[0019] Such as figure 1 As shown, the present invention provides an online measurement method for the microwaviness of a high-generation glass substrate, comprising the following steps:

[0020] a. Along the float flow direction of the glass substrate 1, divide and mark the glass substrate into a group of sampling rectangular blocks 2, and the sampling rectangular blocks 2 are distributed in a rectangular array; the sampling rectangular blocks 2 completely separate and mark the entire glass substrate;

[0021] The size of the sampling rectangular block 2 can be adjusted according to the size of the glass substrate, and the size of the sampling rectangular block can also be inconsistent, as long as the entire glass plate is fully separated and marked;

[0022] B, the central line of each sampling rectangular block is used as the sampling line 3, and the sampling line 3 is perpendicular to the flow direction of the float;

[0023] Each sampling line is defined by the coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com