Environment-friendly waste gas treatment device

An exhaust gas treatment device and exhaust gas treatment technology are applied in combined devices, fixed filter elements, filter separation, etc., which can solve problems such as insufficient energy saving and environmental protection, single structure, and poor filtration and purification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

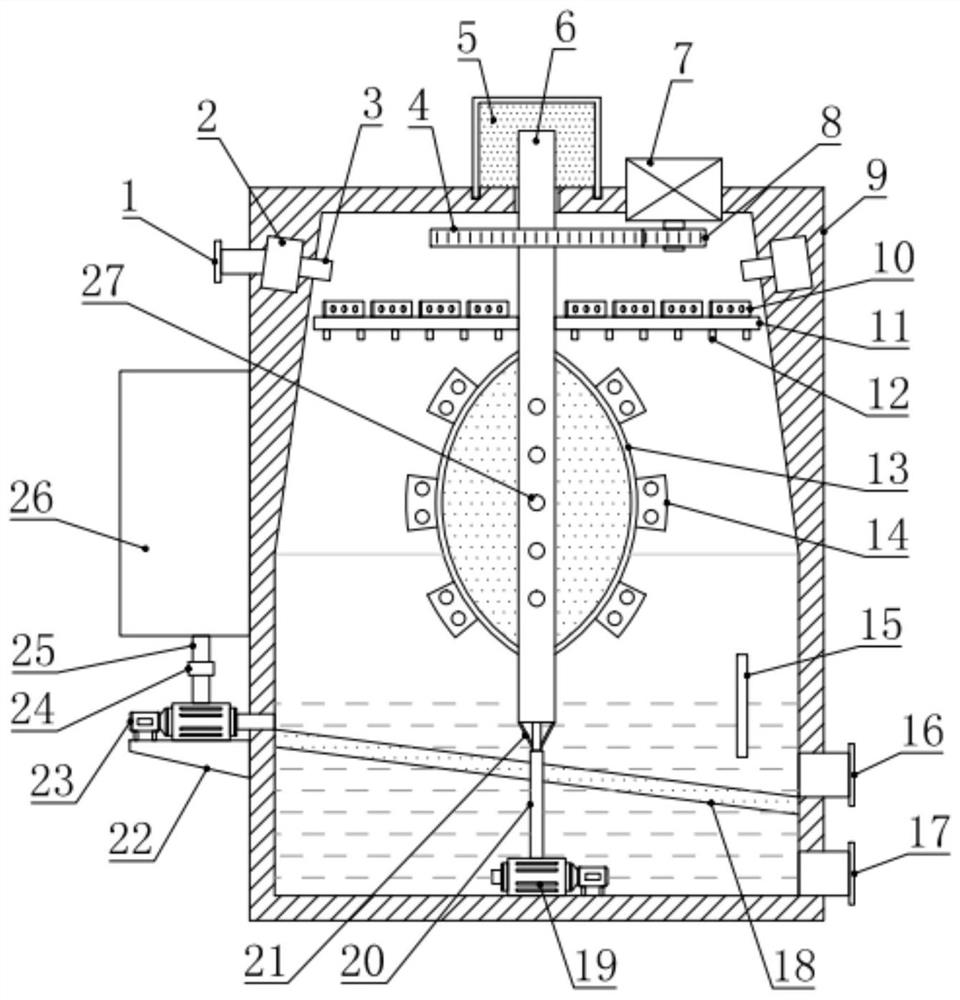

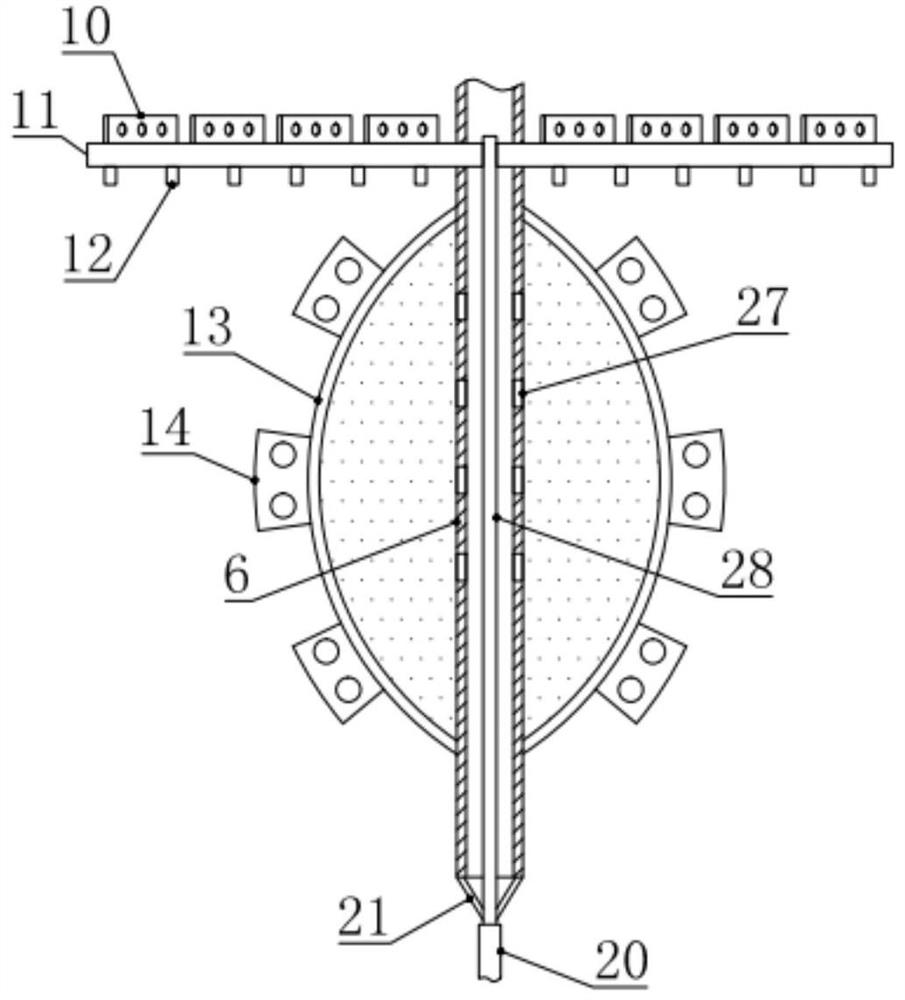

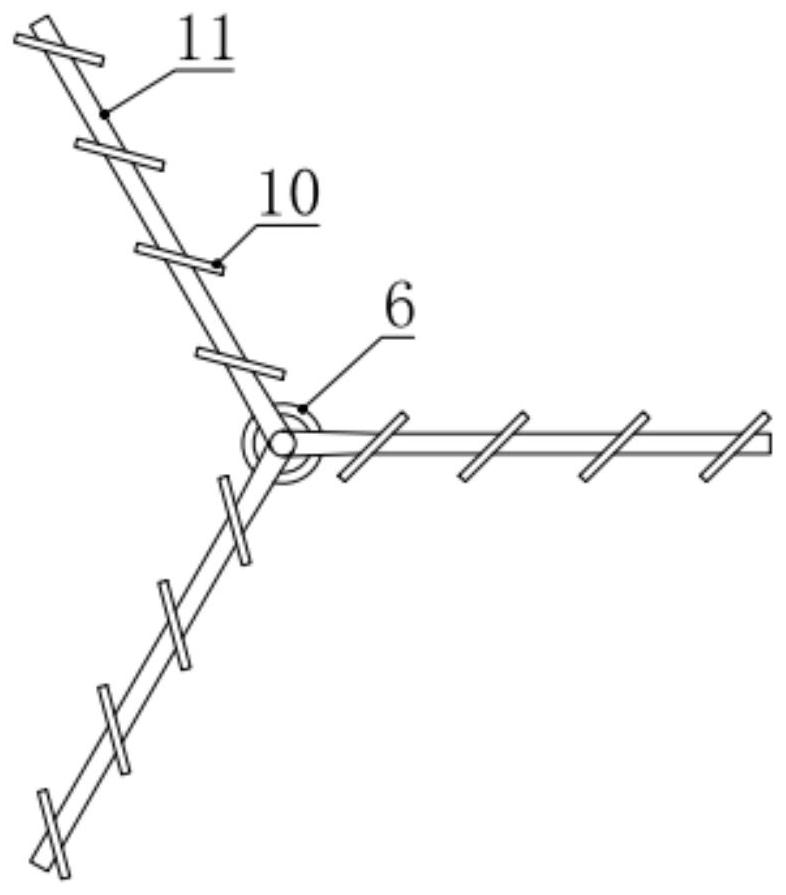

[0018] see Figure 1-2 , in the embodiment of the present invention, a waste gas treatment device for environmental protection includes a waste gas treatment box 9, a center pipe 6 is installed in the middle of the waste gas treatment box 9, and a center pipe 6 for driving the center pipe is also installed on the waste gas treatment box 9. 6 rotating drive components, the central pipe 6 in the exhaust gas treatment box 9 is equipped with a filter screen cylinder 13, and a number of second stirring blades 14 are installed on the outside of the filter screen cylinder 13, and the central pipe 6 in the filter screen cylinder 13 Several exhaust holes 27 are provided, and a plurality of spray pipes 11 are installed circumferentially on the central pipe 6 above the filter screen cylinder 13, and a plurality of atomizing nozzles 12 are installed on the lower side of the spray pipe 11. The upper side of the shower pipe 11 is equipped with a plurality of first stirring blades 10, and th...

Embodiment 2

[0021] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0022] In this example, if figure 1 and 2 As shown, the central pipe 6 is sealed and rotationally connected to the top of the exhaust gas treatment box 9, and the central pipe 6, the communication pipe 28 and the water delivery pipe 20 are coaxially arranged. In order to improve the structural stability of the communication pipe 28, the central pipe 6 The lower end is also provided with a plurality of diagonal struts 21 distributed circumferentially, the lower ends of the diagonal struts 21 are connected and fixed to the connecting pipe 28, and the connecting pipe 28 can be stably supported by the diagonal struts 21, which is beneficial to the remaining water in the central pipe 6. Discharge from the lower end of the central tube 6.

[0023] The driving assembly includes a driven gear 4, a servo motor 7 and a driving gear 8. The driven gear 4 is fixed on the center pipe 6 at the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com