Scraping mechanism for production line

A production line and material scraping technology, which is applied in the direction of cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problem that debris and dust cannot be cleaned in time, affect the operation effect of the production line, and have low precision of mechanical components, etc. problems, achieve good air quality, avoid direct stacking and external contact, and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

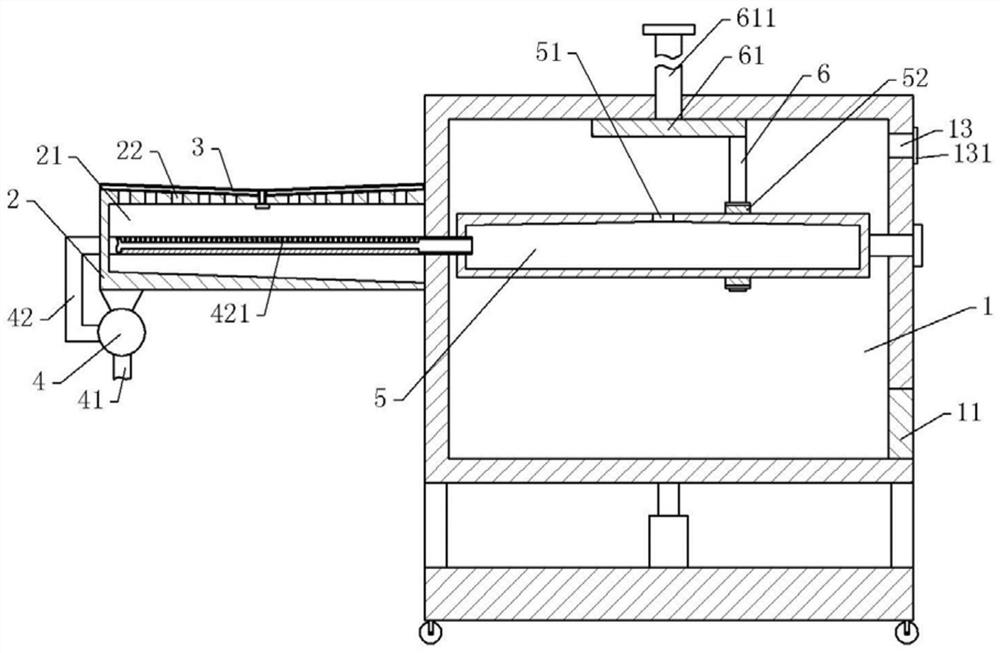

[0038] Scraping mechanism for production line, basically as attached figure 1 As shown, it includes a collection part and a scraping part. The collection part includes a collection box 1 and a collection plate 2 fixed on the left side wall of the collection box 1. The right bottom of the collection box 1 is provided with a discharge port, and the discharge port is provided with Sealing plug 11. The bottom of the collection box 1 is also provided with a base, and four corners of the bottom of the base are provided with moving wheels; The four corners of the upper surface of the base are also welded with telescopic rods, and the top of the telescopic rods is welded to the bottom of the collection box 1 .

[0039] The collecting plate 2 is provided with a material guiding channel 21, the right end of the material guiding channel 21 runs through the collecting plate 2, and the material guiding channel 21 is inclined downward from left to right; The surface is also provided with a ...

Embodiment 2

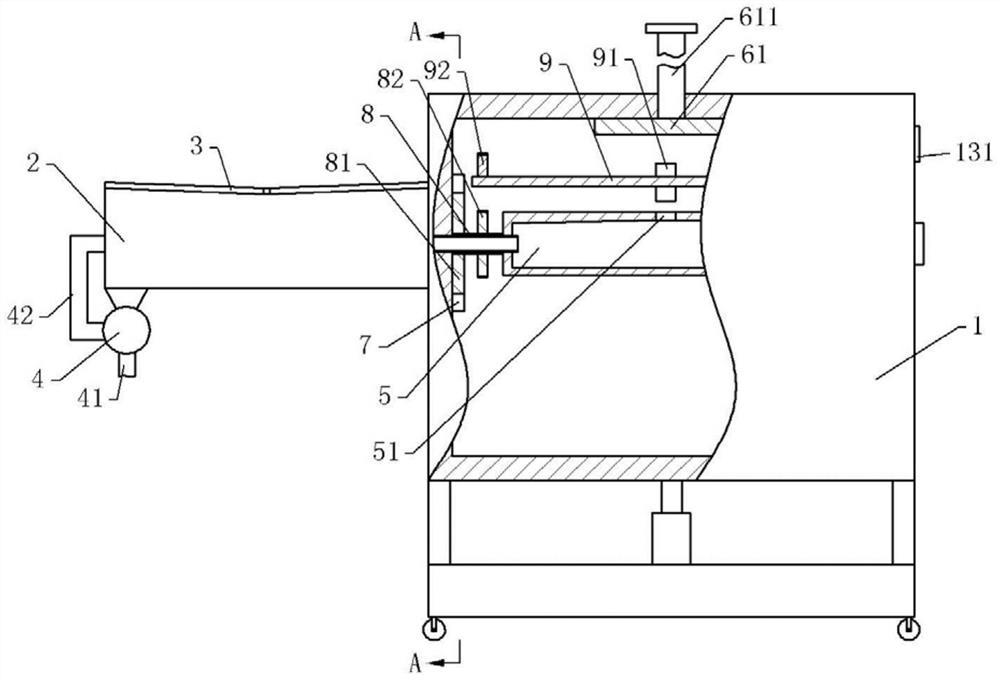

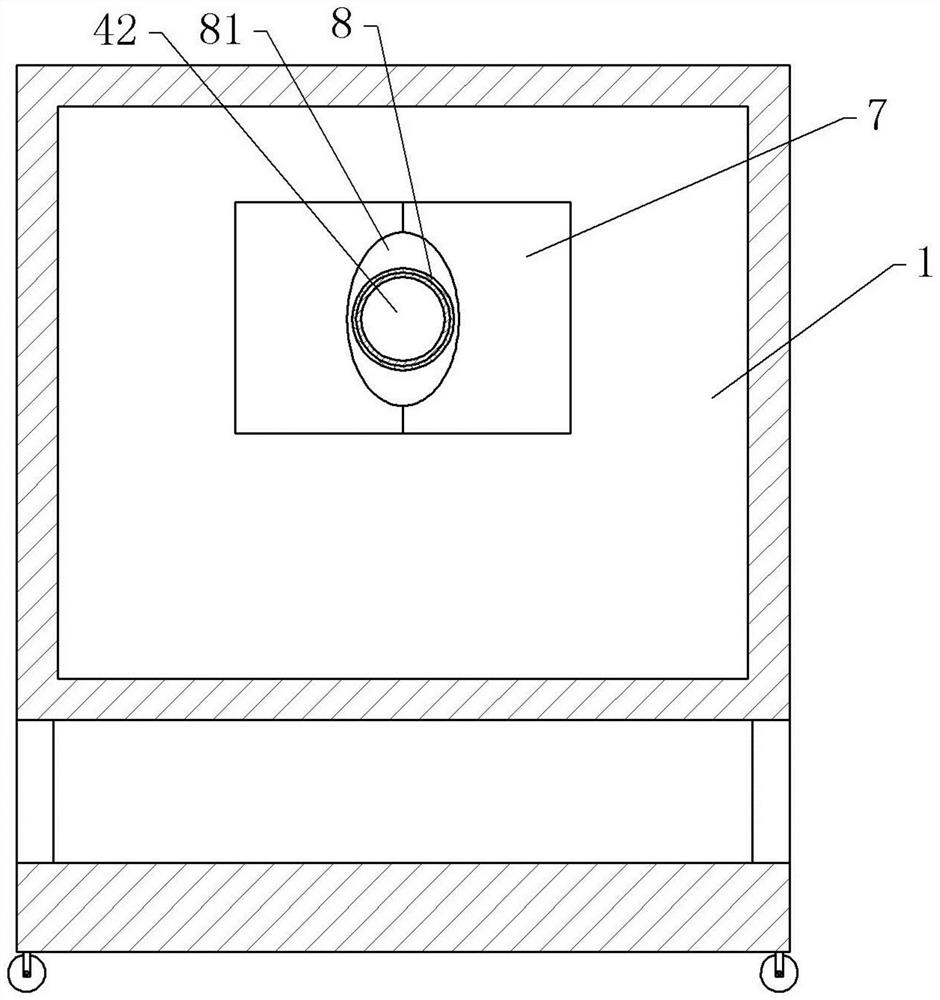

[0054] Embodiment 2 differs from Embodiment 1 only in that, as figure 2 Shown, in the present embodiment, also be provided with two baffles 7 that can close the collecting port, combine image 3 As shown, the inner wall of the collection box 1 is provided with two slide grooves respectively located on the left and right sides of the collection port, and the baffle plate 7 is provided with sliding blocks that cooperate with the slide grooves, so that the baffle plate 7 can be moved horizontally along the slide groove. slide. The opposite sides of the two baffle plates 7 are provided with gaps, and the splicing of the two gaps is oval; Springs are welded between the bottom and the bottom.

[0055] The diffusion section of the dust outlet pipe 42 is provided with a sleeve 8 coaxially with the dust outlet pipe 42, and the sleeve 8 is rotatably connected with the dust outlet pipe 42. The sleeve 8 is also coaxially fixed with an oval The driving block 81 is located in the notch,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com