Metal bending machine with drying, pressing and timing functions

A bending machine, metal technology, applied in metal processing, metal processing equipment, forming tools and other directions, can solve the problems of poor appearance, increase production and processing costs, reduce processing qualification rate, etc., to save manpower, improve qualification rate, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

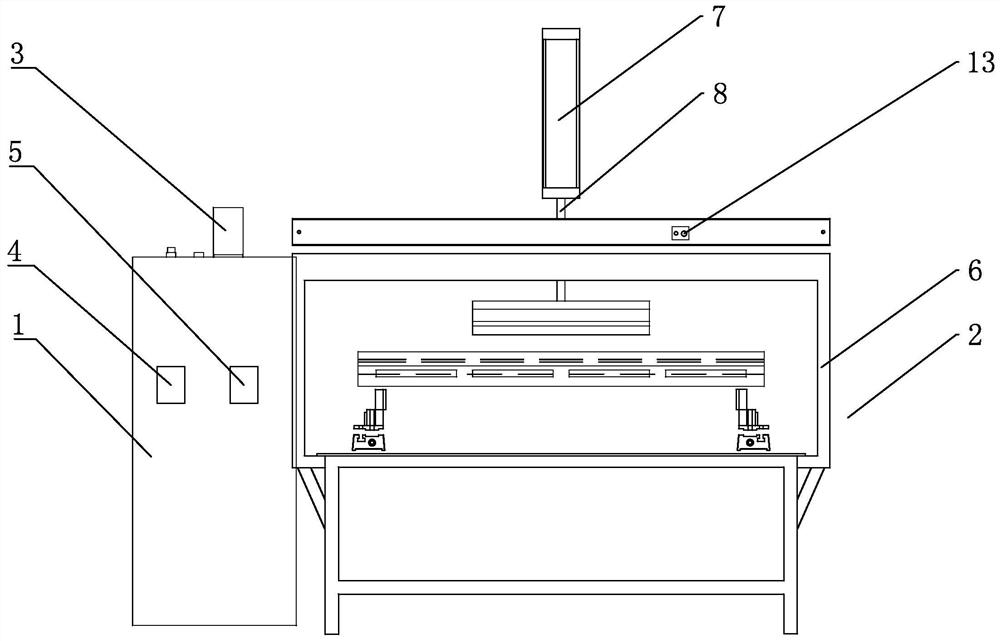

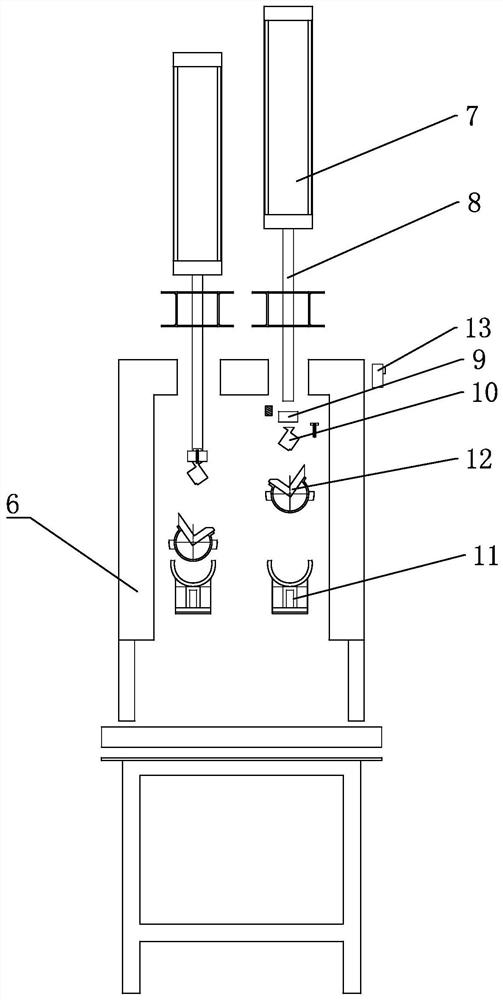

[0019] Shown in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

[0020] Such as Figure 1-2 As can be seen from the diagram, a metal bending machine with a timing function for baking and pressing includes a main control cabinet 1 and a bending tool 2. The top of the main control cabinet 1 is provided with an audible and visual alarm lamp 3, and the main control cabinet 1 1. A temperature control module 4 and a timing module 5 are arranged on the front side; the bending tool 2 includes a bracket 6, the top of the bracket 6 is provided with a cylinder 7, and the lower side of the cylinder 7 passes through the top of the bracket 6 and is provided with a telescopic rod downward 8; the lower side of the telescopic rod 8 is provided with a connecting block 9, and the lower side of the connecting block 9 is provided with an upper mold 10; the upper side of the bottom of the bracket 6 is provided with a support block 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com