Baking device with uniform heat conduction function for blade production

A baking device and blade technology, applied in the direction of heating device, drying, drying machine, etc., can solve the problems of burns, affecting the baking effect, increasing the workload of operators, etc., to increase the workload and improve the connection stability , Improve the effect of baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

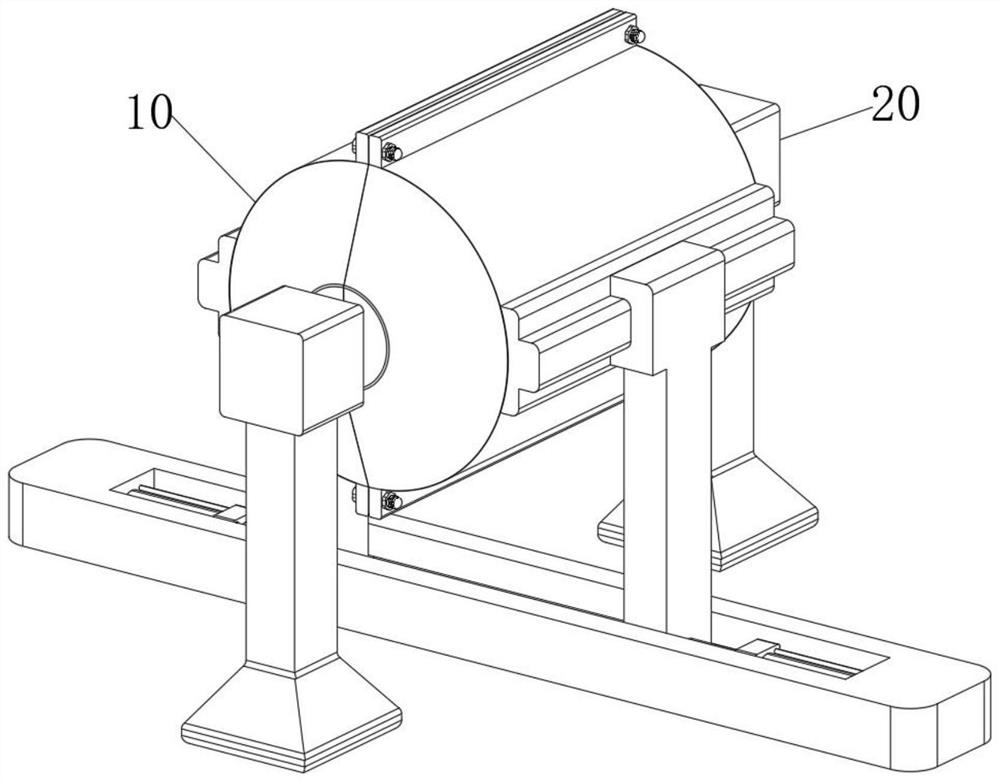

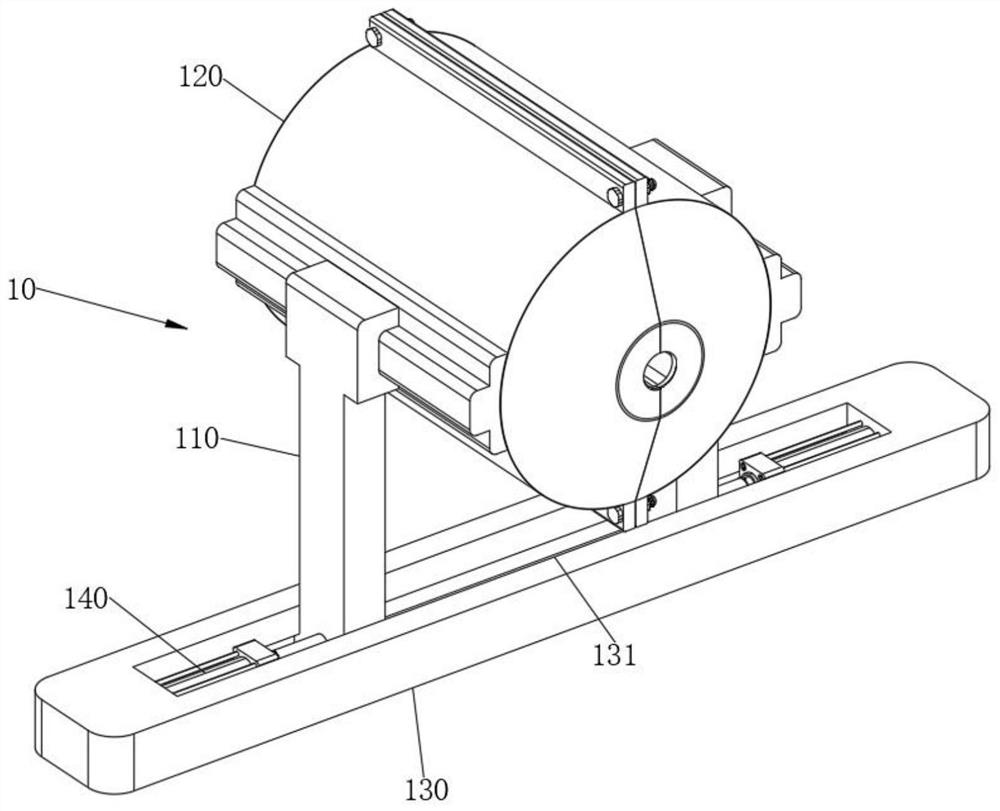

[0043] see Figure 1-Figure 10 As shown, the purpose of this embodiment is to provide a uniform heat conduction blade production baking device, including an external baking mechanism 10 and an internal baking mechanism 20 installed at the inner end of the external baking mechanism 10. The external baking mechanism 10 Include at least:

[0044] pillar 110, a pair of pillars 110 are provided;

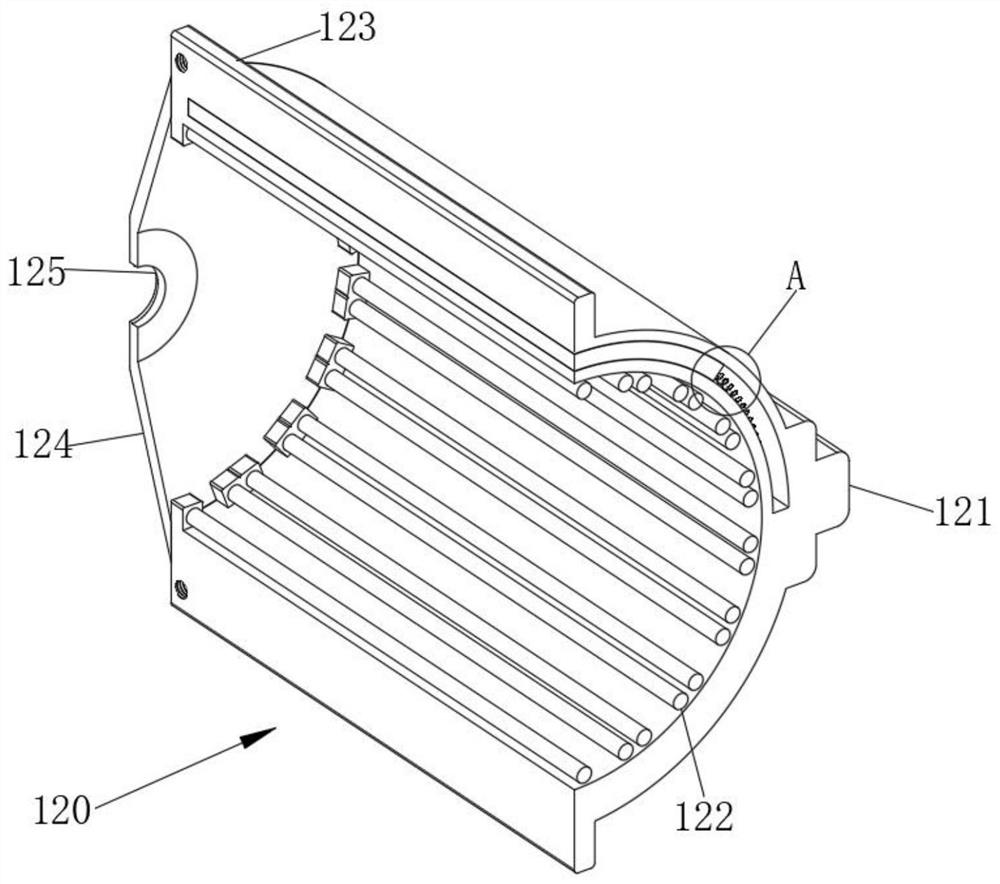

[0045]Half collar 120, a pair of half collar 120 is provided, the sides of the two half collars 120 are provided with side plates 121, the side plates 121 are respectively fitted with the tops of the two pillars 110, and the inside of the half collar 120 is provided with several high-temperature lamps tube 122;

[0046] The internal baking mechanism 20 includes at least:

[0047] The inner core 210, the inner core 210 includes a high-temperature wick 211, the outer side of the high-temperature wick 211 is provided with a jacket 212, and the outer side of the outer jacket 212 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com