A kind of high blackness matte ASA composite material and preparation method and application thereof

A composite material and high blackness technology, which is applied in the field of high blackness matte ASA composite material and its preparation, can solve the problems of high cost, insufficient blackness, large fluctuation of physical and mechanical properties, etc., and achieves wide applicability and mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

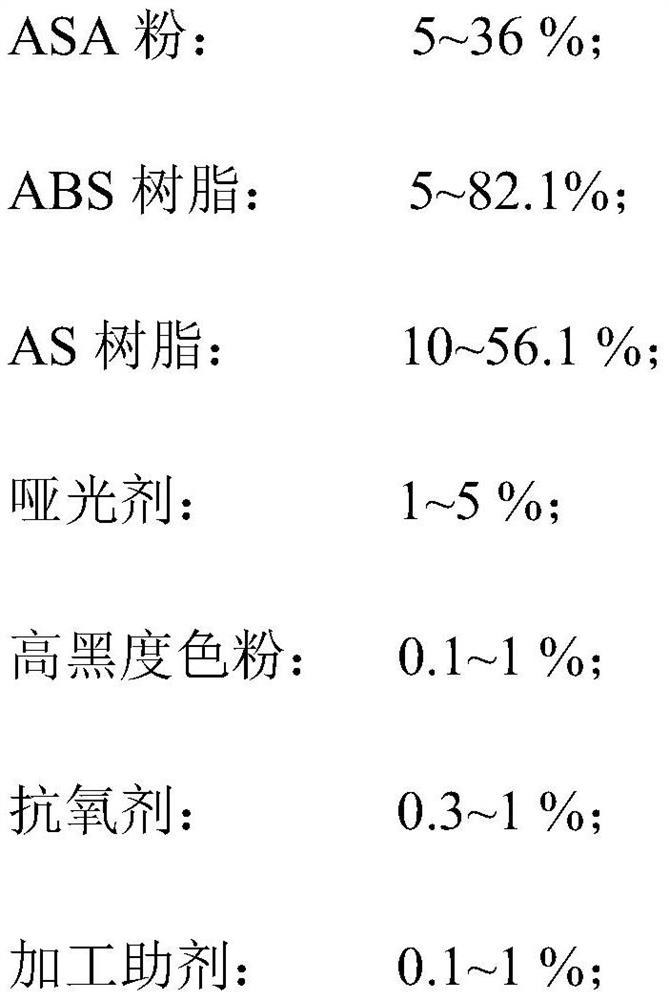

Method used

Image

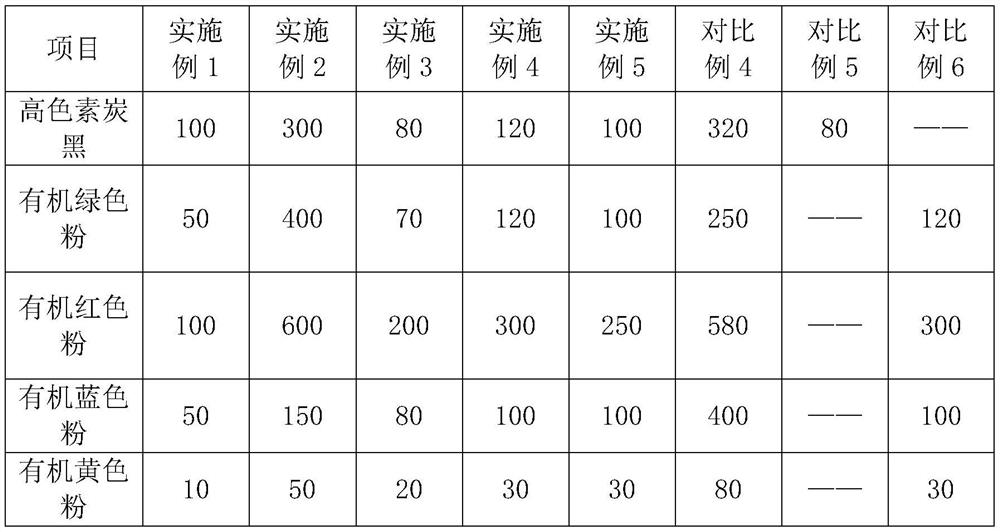

Examples

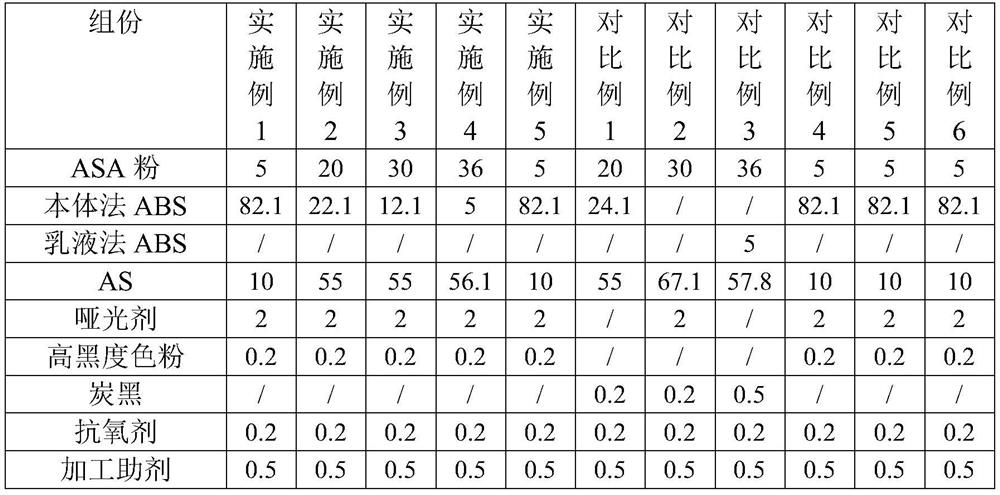

Embodiment 1-4

[0039] According to the raw material formula in Table 1, fully mix ASA powder, bulk ABS resin, AS resin, matt agent, toner, and auxiliary agent in a high-speed mixer for 10-60 minutes in a high-speed mixer; convey the above-mentioned mixture through a precisely metered feeding device In the twin-screw extruder, the screw temperature of each section of the extruder is controlled between 180 and 230°C, the length-diameter ratio of the twin-screw extruder is 25-40, and the screw speed is 200-800 rpm. Under the shearing, kneading and conveying of the screw, the material is fully melted and compounded, and then the ASA compound is obtained by extrusion, granulation and drying; the ASA compound is added to the injection molding machine and processed into the desired splines. The conditions are: the barrel temperature is 190-240°C, the mold temperature is 60-70°C, and the injection pressure is 6-10MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com