A self-propelled anti-icing material based on modulus patterning and its preparation method

A self-driven, modulus technology, applied to flat products, other household appliances, coatings, etc., can solve the problems of unsustainable anti-icing effect and insufficient anti-icing performance, and achieve large-scale production and stable anti-icing performance , the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

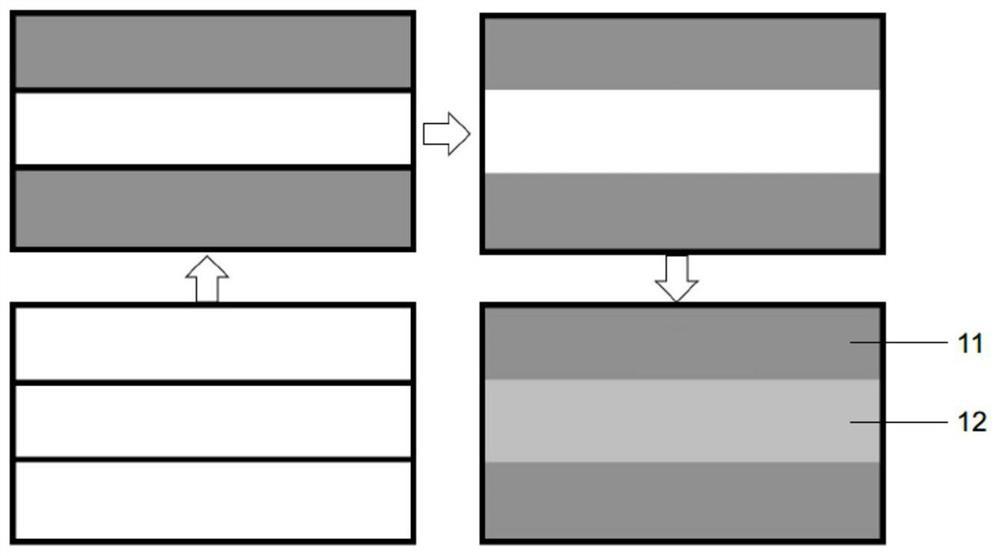

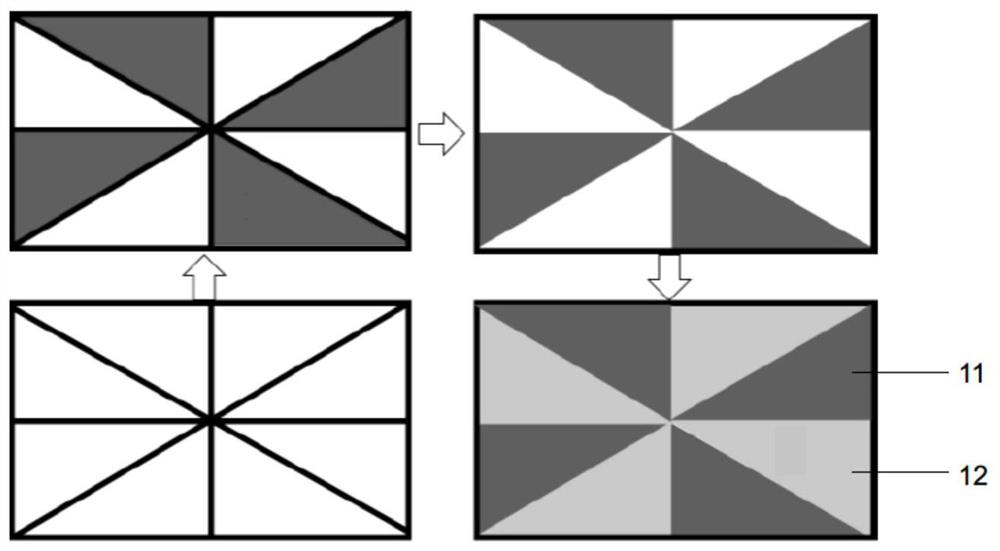

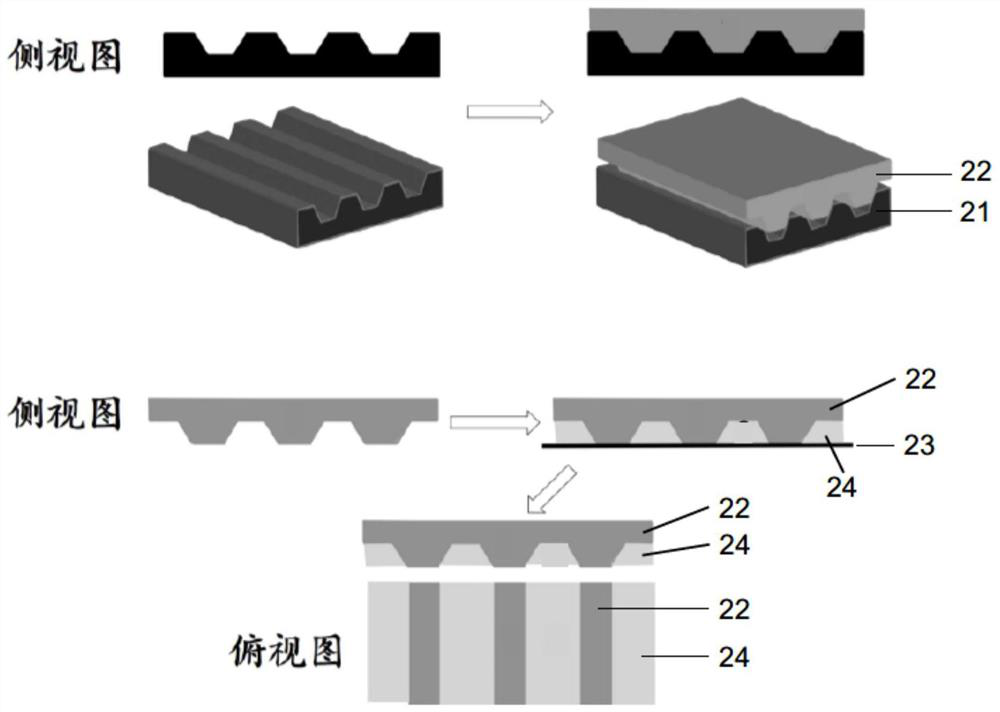

[0041] Preparation method of self-propelled anti-icing material

[0042] The self-propelled anti-icing material of the present invention can be made by various methods, and the specific method can be selected according to factors such as the scale and shape of the modulus pattern, and the properties of raw materials. Taking PDMS (polydimethylsiloxane) as the base material as an example, several optional methods are given below. The process of preparing patterns with other basic materials can be referred to.

[0043] Preparation Method 1: Heat Curing

[0044] This method is suitable for processing modulus patterned materials with a centimeter-scale scale, and it can also be selected for processing materials with other scales depending on the situation.

[0045] Step 1: Design a modulus pattern (such as bar, square, circle, etc.), and make a mold with detachable partition baffles according to the designed modulus pattern.

[0046] Step 2: Inject a specific proportion of PDM...

Embodiment 1

[0062] Mix the PDMS monomer and the curing agent at a ratio of 1:1 to obtain a precursor, stir evenly and place it in a vacuum oven to remove air bubbles at room temperature. Pour the precursor into a glass mold with a flat bottom, cure at 80°C for 2 hours, and demould for storage.

Embodiment 2

[0064] Mix the PDMS monomer and curing agent at a ratio of 20:1 to obtain a precursor, stir evenly and place it in a vacuum oven to remove air bubbles at room temperature. Pour the precursor into a glass mold with a flat bottom, cure at 80°C for 2 hours, and demould for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com