Composite three-dimensional sandwich flame-retardant heat insulating decorative board

A flame retardant thermal insulation, composite technology, applied in covering/lining, building, building structure, etc., can solve the problems of complicated construction procedures, poor temperature resistance, poor water absorption, etc., and achieve high construction efficiency and good overall performance. , Good sound insulation and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

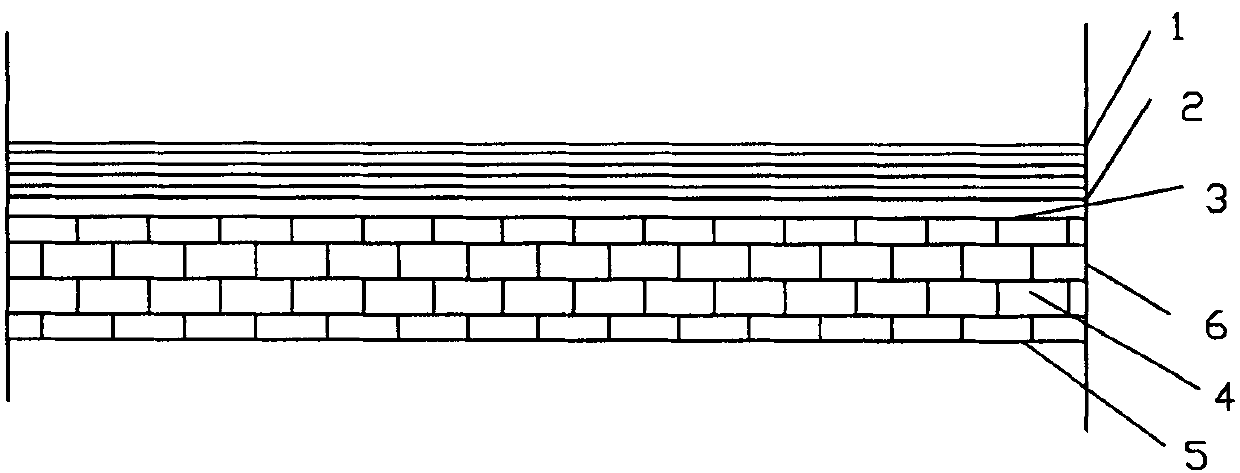

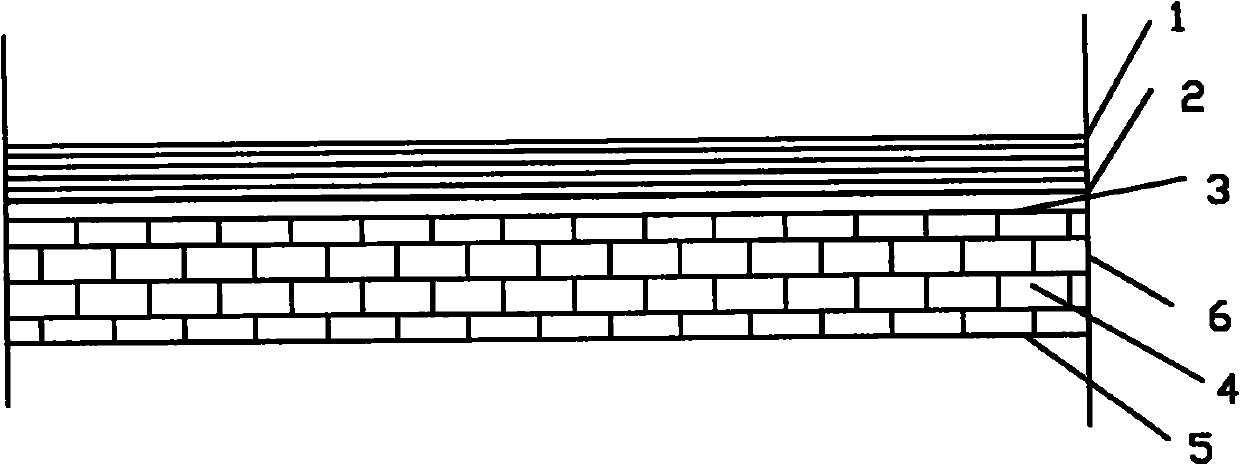

[0022] as attached figure 1 As shown, a composite three-dimensional sandwich flame-retardant thermal insulation decorative board includes an inorganic material composite board layer 1 and a three-dimensional sandwich layer 6 through a bonding layer 2, and the bonding layer 2 is arranged on the inorganic material composite board 1 and the three-dimensional sandwich layer Between the layers 6, the thickness of the adhesive layer 2 is 0.1-1mm. The composite plate layer 1 of inorganic materials is determined according to the requirements, and can be cement board, calcium silicate layer, silicate layer, gypsum board or aluminum board. The three-dimensional sandwich layer 6 includes an upper fabric surface 3, an intermediate core material structure 4 and a lower fabric surface 5. The intermediate core material structure 4 uses the three-dimensional sandwich fabric material as a support body, lightweight aggregate as a filling matrix, and the three-dimensional sandwich fabric material...

Embodiment 2

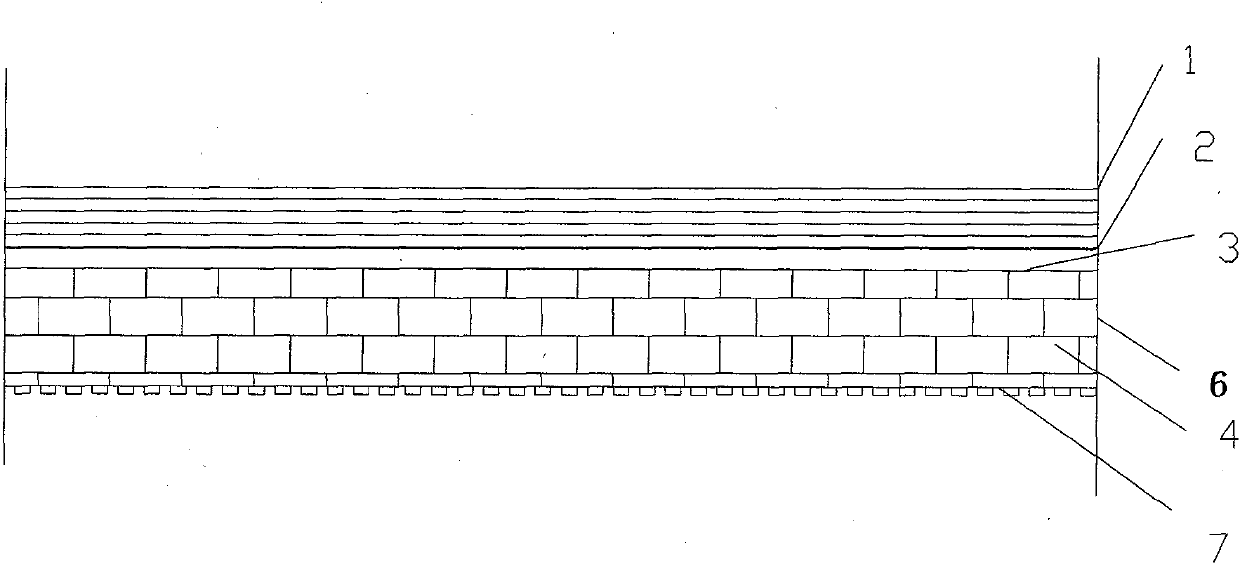

[0024] as attached figure 2 As shown, a composite three-dimensional sandwich flame-retardant thermal insulation decorative board includes an inorganic material composite board layer 1 and a three-dimensional sandwich layer 6 through a bonding layer 2, and the bonding layer 2 is arranged on the inorganic material composite board 1 and the three-dimensional sandwich layer Between the layers 6, the thickness of the bonding layer 2 is 0.1-1mm. The composite plate layer 1 of inorganic materials is determined according to the requirements, and can be cement board, calcium silicate layer, silicate layer, gypsum board or aluminum board. The three-dimensional sandwich layer 6 includes an upper fabric surface 3, an intermediate core material structure 4 and a lower fabric surface 5. The intermediate core material structure 4 uses the three-dimensional sandwich fabric material as a support body, lightweight aggregate as a filling matrix, and the three-dimensional sandwich fabric material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com