A kind of gas control method for self-relief pressure and outburst fast excavation in adjacent empty roadway

A self-relieving pressure and roadway technology, which is applied in the direction of gas discharge, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of limited pressure relief area of large-diameter drilling, uneven distribution of holes, complex technical process, etc., to achieve The effect of reducing the risk of outburst, increasing the permeability of the coal seam, and increasing the scope of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

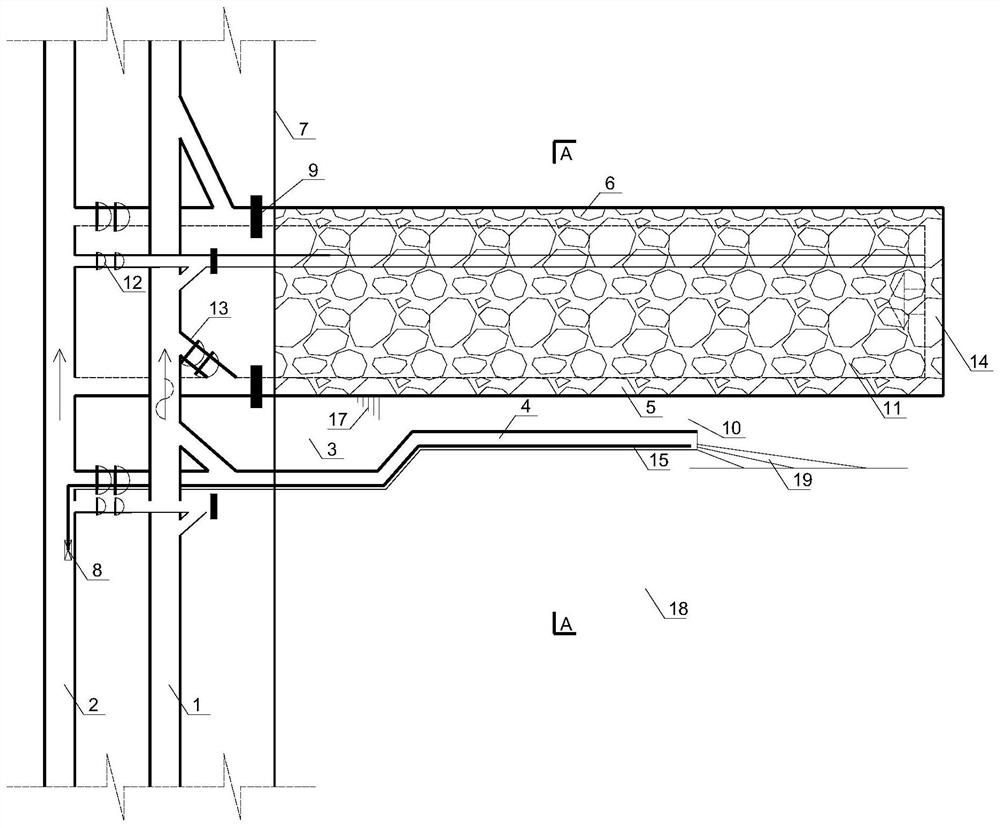

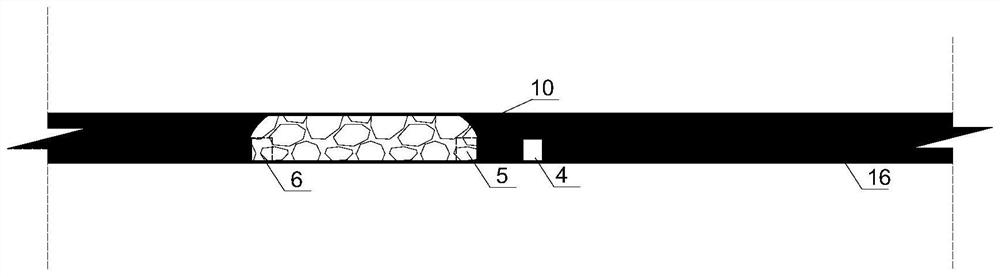

[0030] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Certain embodiments of the present invention will be described more fully hereinafter with reference to the accompanying drawings, some, but not all embodiments, of which are shown. Indeed, various embodiments of the present invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth in this number; rather, these embodiments are provided so that this invention will satisfy applicable legal requirements.

[0031] In the description of the present invention, it should be noted that the orientations or positional relationships indicated by the terms "inside", "outside", "upper", "lower", "front", "rear", etc. are based on those shown in the accompanying draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com