Stepped shaft straightness detection device and straightness detection method thereof

A technology for detection devices and stepped shafts, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of pressure deformation, inability to realize automatic measurement of stepped shafts, and large errors, so as to improve measurement accuracy and speed, and realize full The effect of automated measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is aimed at measuring the flatness of the long stepped shaft which is difficult to achieve. The existing pressure head sensor measurement method has the disadvantages of pressure deformation and large error, and it is impossible to realize automatic measurement of the stepped shaft. During the rotation process of the shaft body A stepped shaft straightness detection device and its detection method developed because the measurement points cannot be guaranteed to be on the same axis.

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

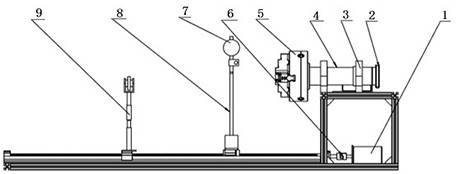

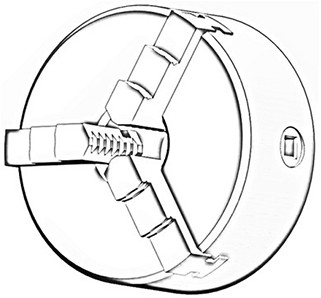

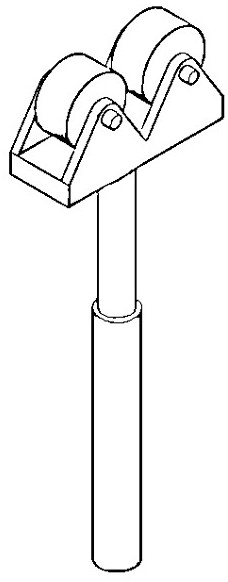

[0031] Such as figure 1 As shown, a stepped shaft straightness detection device includes a self-centering three-jaw chuck 5 with a self-centering function that fixes the end of the stepped shaft and drives the stepped shaft to rotate around the central axis. The movable spring support frame 9 of the shaft, the laser detector 7 for measuring the data of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com