Spacecraft equipment automatic collimation measurement system, collimation method and measurement method

A measurement system and spacecraft technology, applied in the field of measurement of relative attitude relationship between spacecraft equipment, can solve the problem of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These descriptions are only exemplary and are not intended to limit the protection scope of the present invention.

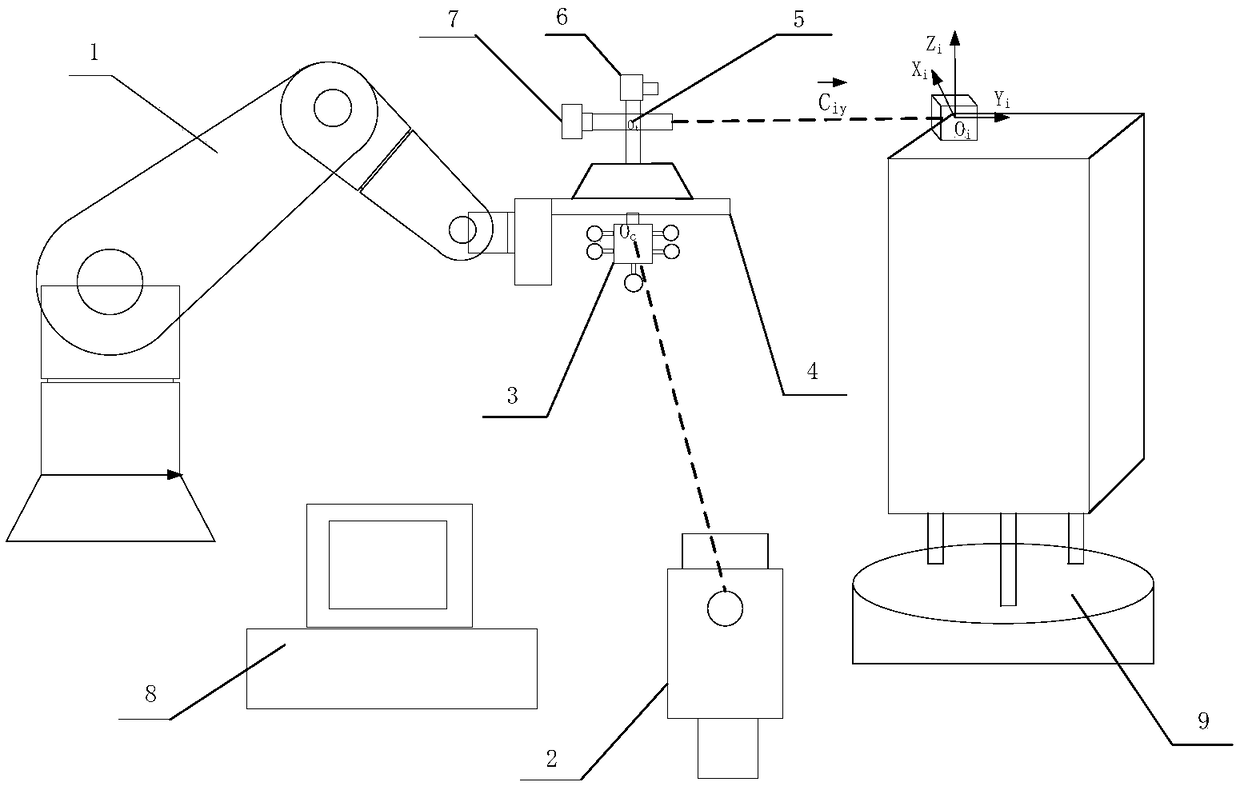

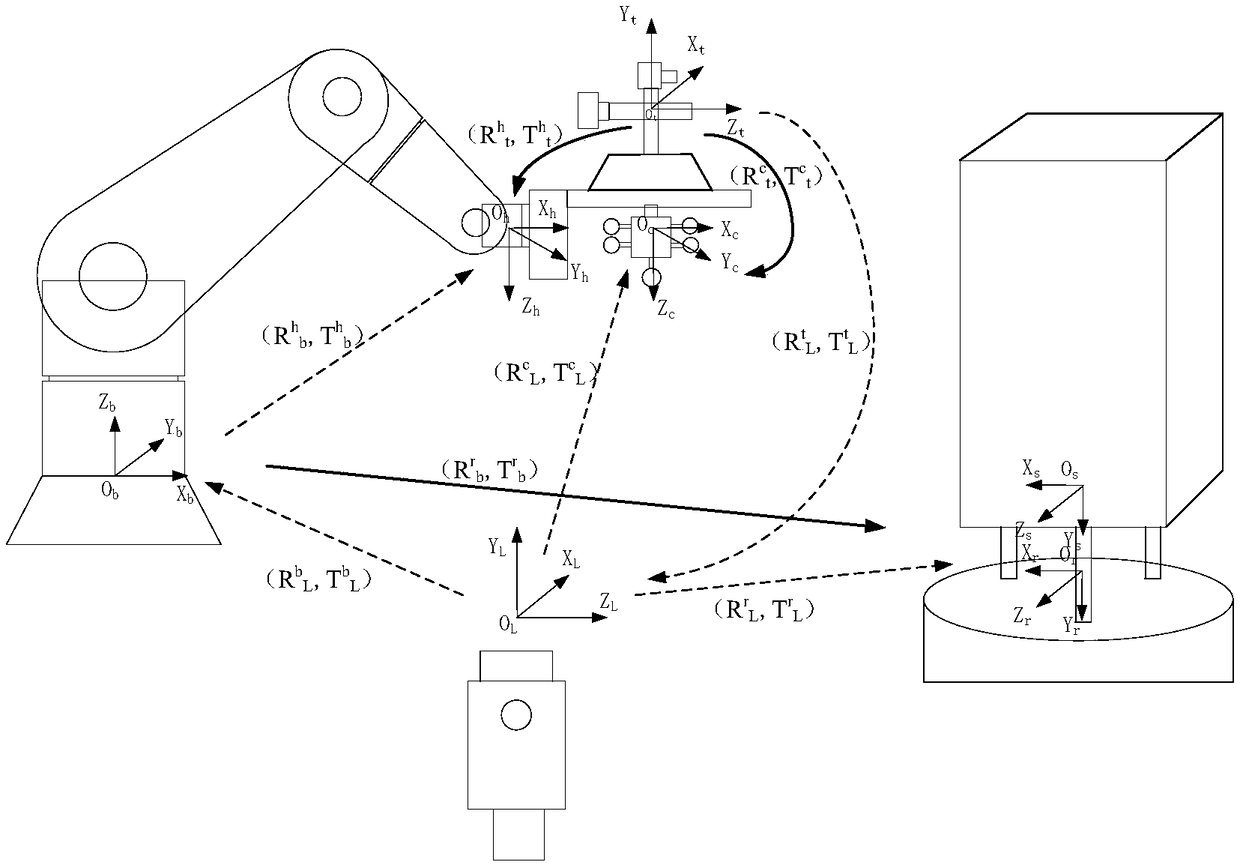

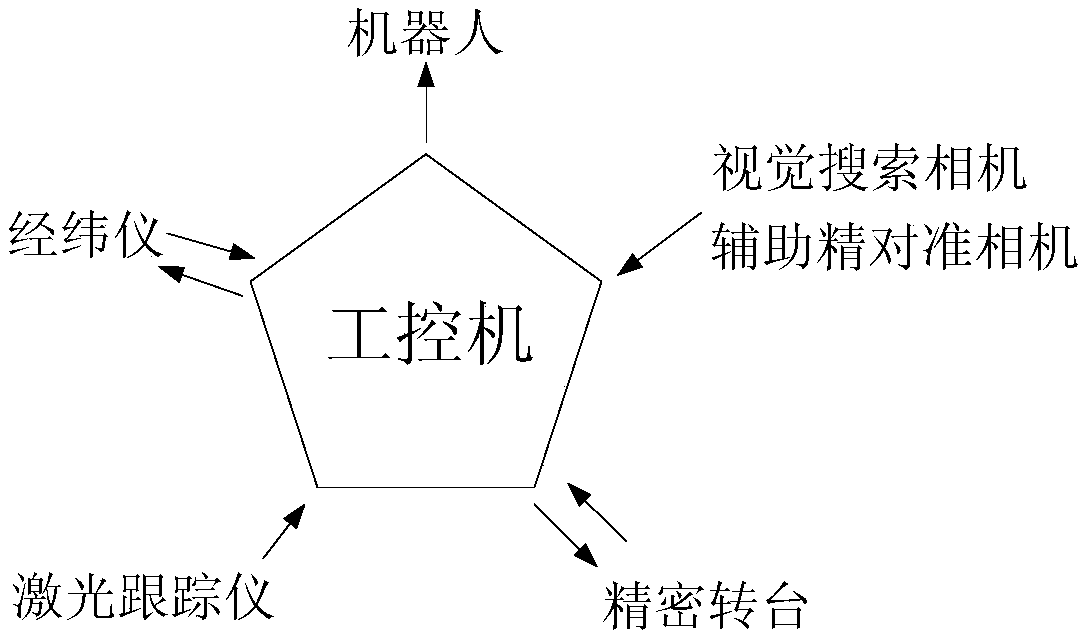

[0059] First, see figure 1 , figure 1 A schematic structural diagram of an attitude angle alignment measurement system between spacecraft equipment based on a combination of robot and theodolite is shown; the measurement device of the present invention includes: a robot 1, a laser tracker 2, a laser tracking target (T-MAC) 3, a robot end Tooling 4, theodolite 5, visual search camera 6, auxiliary precision alignment camera 7, industrial computer 8, precision turntable 9. The theodolite used to align the cube mirror of the spacecraft equipment is fixed on the robot end tooling 4, and the visual search camera used to image the tested product is fixed on the top of the theodolite 5, and the measured object on the spacecraft equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com