Cable-stayed bridge cable bent tower anchoring area prestressed reinforcement impact protection test device and method

A technology of prestressed steel bar and test device, which is applied in the direction of measuring device, using stable tension/pressure test material strength, bridges, etc. problems such as phenomenon and preventive effect test, to ensure the design and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

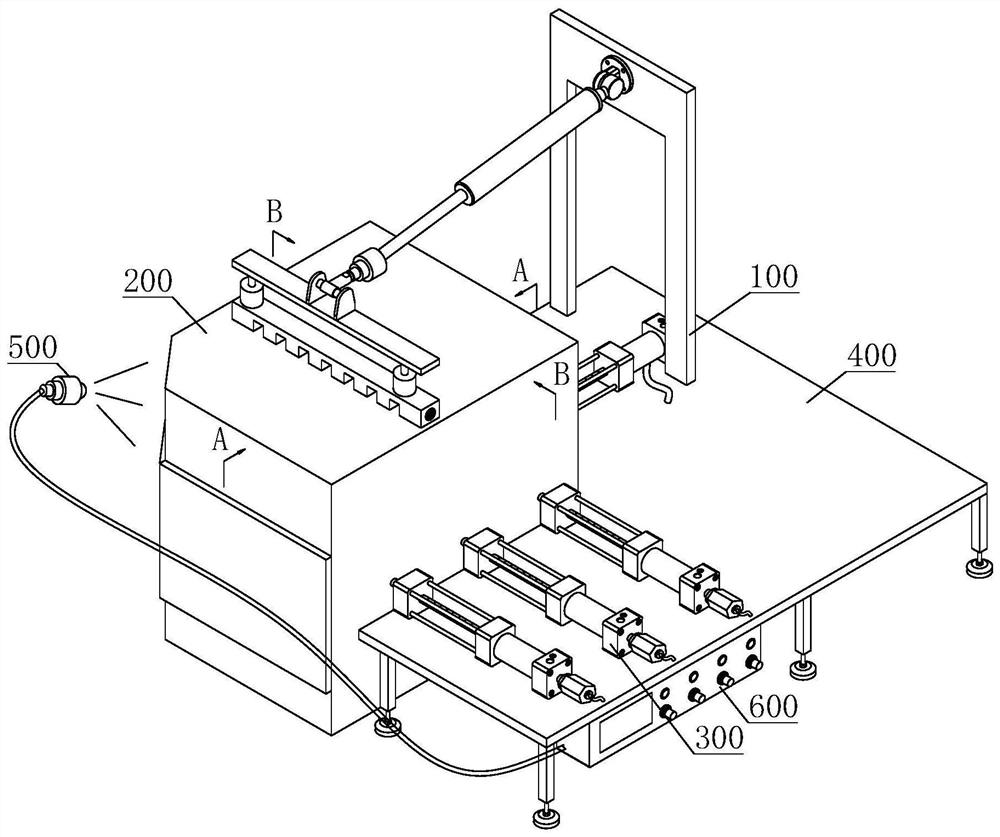

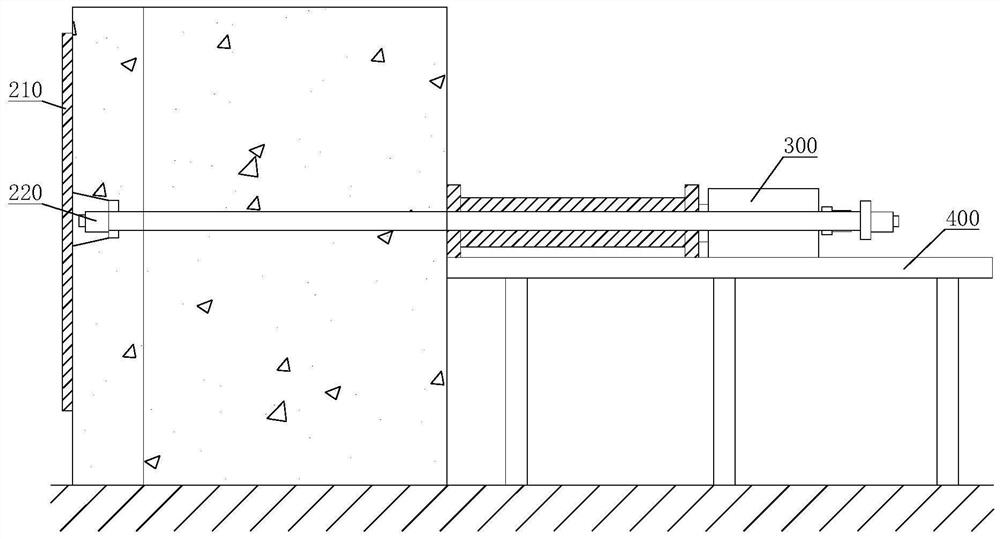

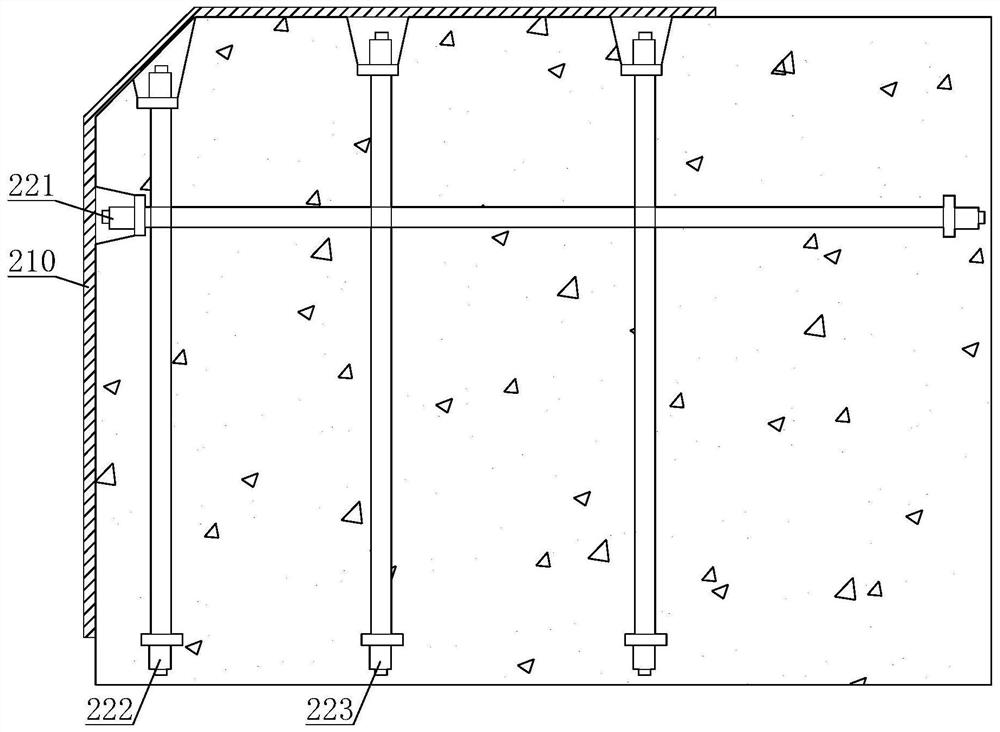

[0064] refer to Figure 1 to Figure 4 , a prestressed reinforcement impact protection test device in the cable tower anchorage area of a cable-stayed bridge, comprising a loading device 100, a concrete model 200, a tension mechanism 300, a tension stand 400, a high-speed camera 500 and an acquisition instrument 600, and a tension stand 400 or more The semi-enclosed form is distributed on the side wall of the concrete model 200, and a plurality of tensioning mechanisms 300 and loading devices 100 are installed on the tensioning pedestal 400. The loading device 100 extends to the place where the concrete model 200 is located and abuts against the concrete from top to bottom. On the upper surface of the model 200, the extension lines of a plurality of tensioning mechanisms 300 are distributed vertically and horizontally and are connected with the concrete model 200. A high-speed camera 500 is arranged obliquely above the concrete model 200. The high-speed camera 500, the tension...

Embodiment 2

[0079] refer to Figure 1 to Figure 4 , a prestressed reinforcement impact protection test device in the cable tower anchorage area of a cable-stayed bridge, comprising a loading device 100, a concrete model 200, a tension mechanism 300, a tension stand 400, a high-speed camera 500 and an acquisition instrument 600, and a tension stand 400 or more The semi-enclosed form is distributed on the side wall of the concrete model 200, and a plurality of tensioning mechanisms 300 and loading devices 100 are installed on the tensioning pedestal 400. The loading device 100 extends to the place where the concrete model 200 is located and abuts against the concrete from top to bottom. On the upper surface of the model 200, the extension lines of a plurality of tensioning mechanisms 300 are distributed vertically and horizontally and are connected with the concrete model 200. A high-speed camera 500 is arranged obliquely above the concrete model 200. The high-speed camera 500, the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com