Printer interface detection device

An interface detection and printer technology, applied in mechanical measuring devices, measuring devices, mechanical devices, etc., can solve problems such as inconvenient operation, lack of rapid detection device for printer interface size, and incomplete detection functions, so as to facilitate collection and unified processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

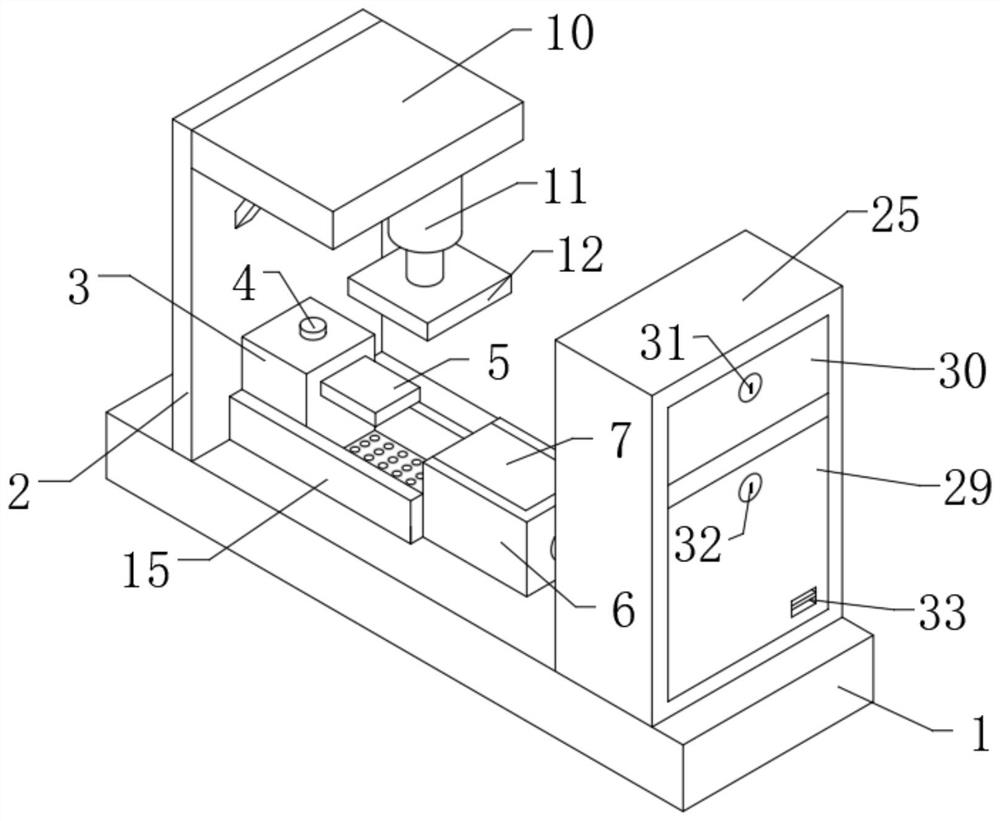

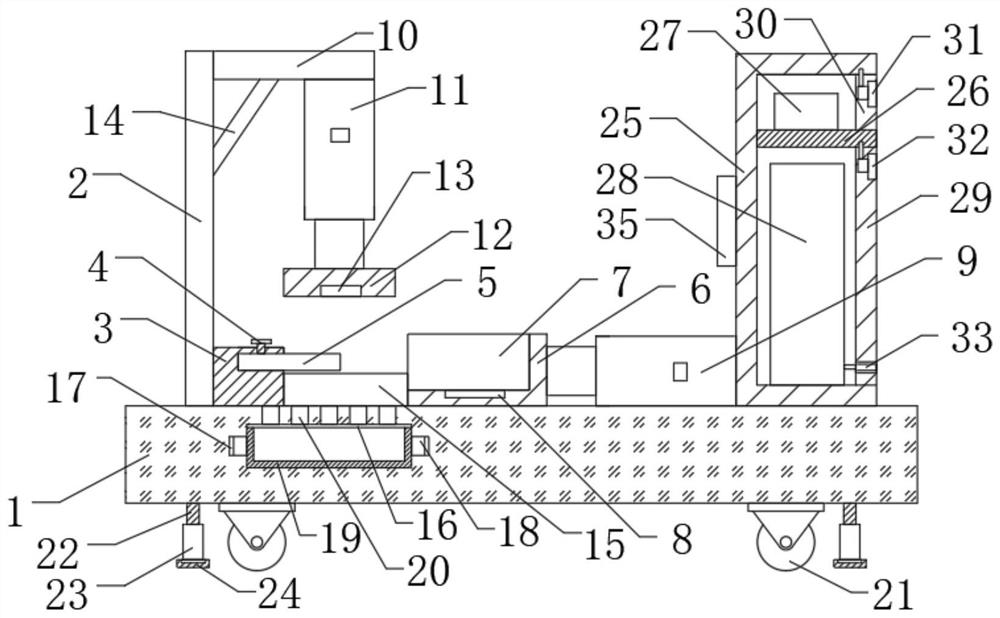

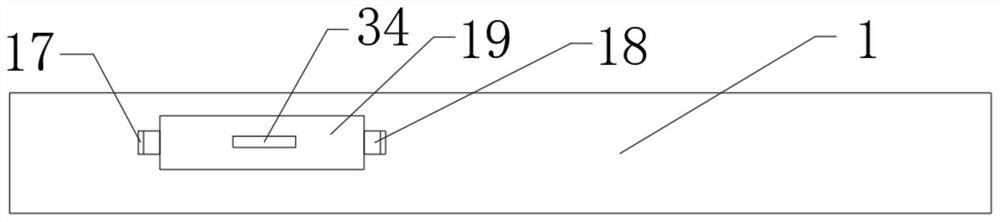

[0029] see Figure 1-5 , the present invention provides a technical solution: a printer interface detection device, including a working platform 1, the upper surface of the working platform 1 is respectively welded with a first plate body 2, a base 3, a first hydraulic cylinder 9 and a box body 25, the base 3 One side is plugged with a plug 5, the top of the base 3 is threadedly connected with a fixing bolt 4, the bottom of the fixing bolt 4 is in close contact with the top of the plug 5, the top of the first board 2 is welded with a second board 10, the second board The bottom of the body 10 is threadedly connected with a second hydraulic cylinder 11, the piston rod of the second hydraulic cylinder 11 is fixedly connected with a pressure plate 12, the inside of the pressure plate 12 is equipped with a second pressure sensor 13, and the piston rod of the first hydraulic cylinder 9 is fixedly connected with a The first housing 6, the bottom of the first housing 6 is equipped wi...

Embodiment 2

[0033] The present invention also provides an embodiment different from the first embodiment, which is different from the first embodiment:

[0034] The electrical output end of the USB charging port 33 is electrically connected to the electrical input end of the storage battery 28, the electrical output end of the storage battery 28 is electrically connected to the electrical input end of the switch group 35, and the electrical output end of the switch group 35 is connected to the electrical input end of the switch group 35. The electrical input terminals of the PLC board 27 are electrically connected, and the electrical output terminals of the PLC board 27 are respectively connected to the electrical input terminals of the first hydraulic cylinder 9, the first pressure sensor 8, the second hydraulic cylinder 11 and the second pressure sensor 13 Electrically connected, the signal transmission end of the PLC board 27 is respectively connected to the signal transmission end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com