Multifunctional full-automatic meat smashing machine

A fully automatic and multi-functional technology, applied in the direction of meat tenderization, processing meat, softening by beating meat, etc., can solve the problems of speeding up the production time, reducing the taste, inconvenient to smashing meat, etc., to reduce labor costs, increase income, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

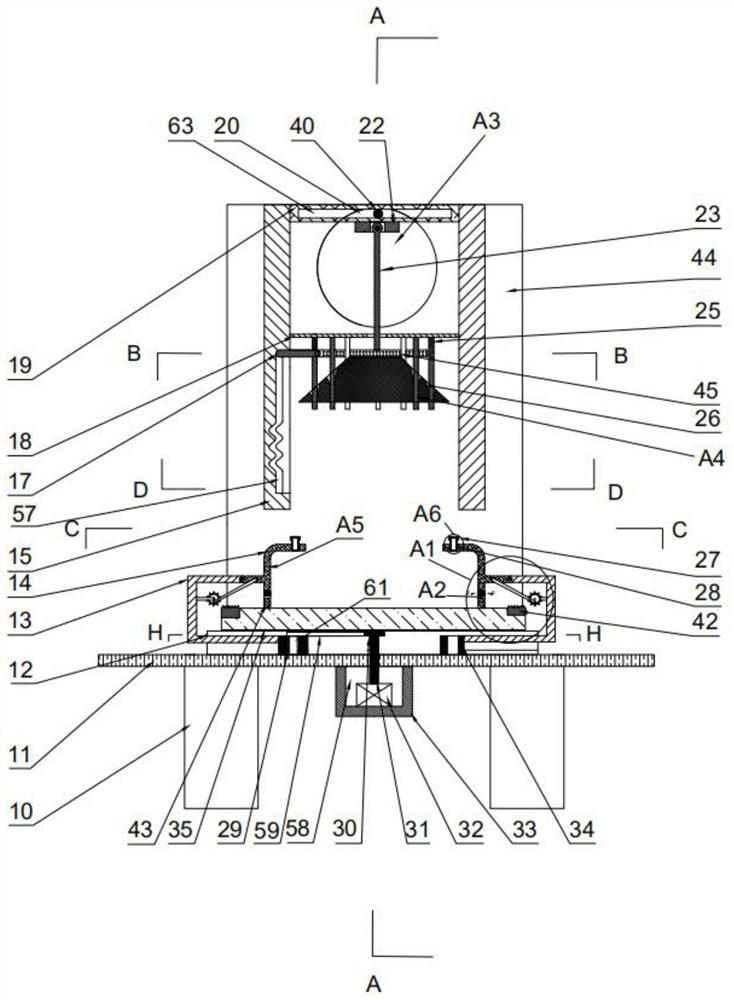

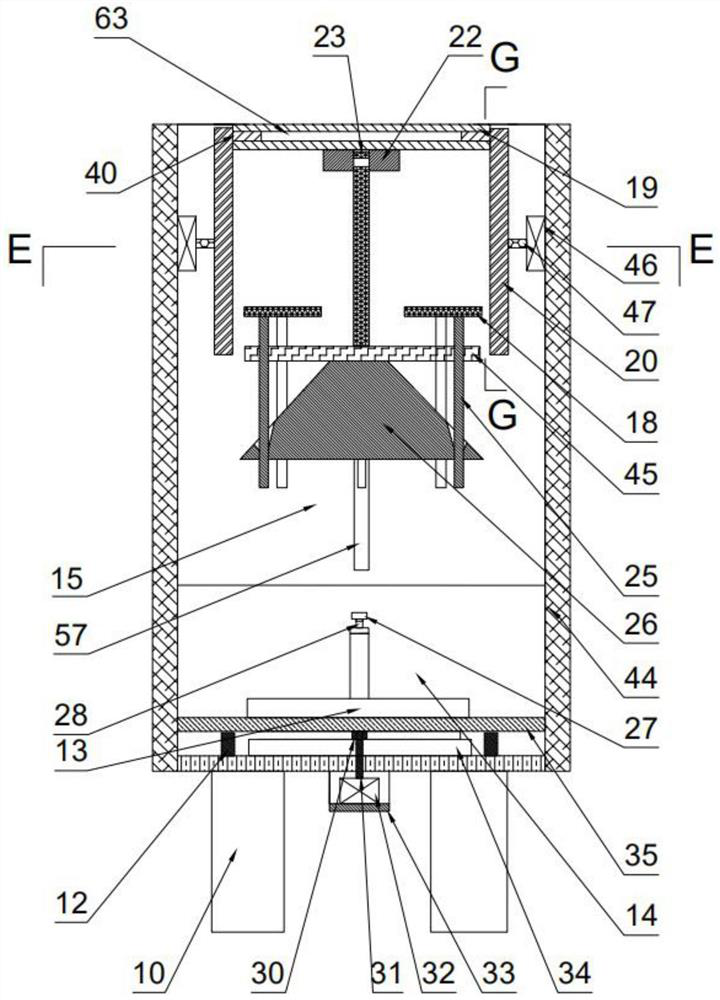

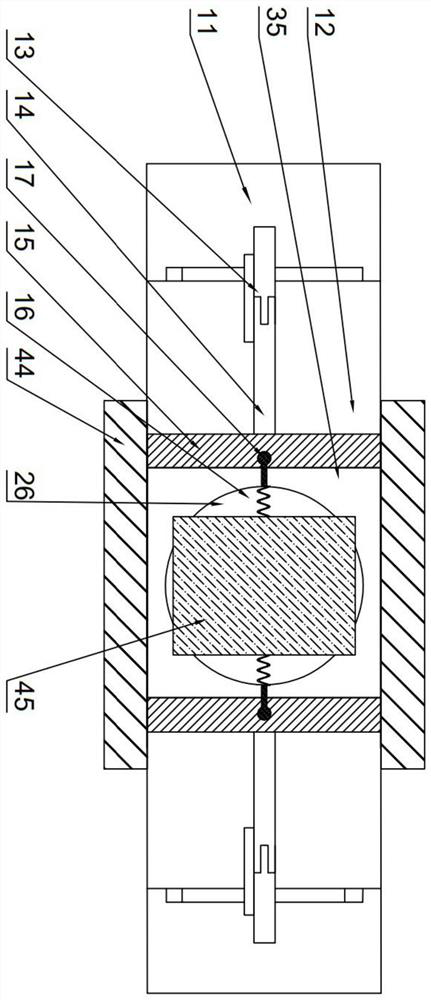

[0023] combine figure 1 and figure 2 As shown, a multi-functional fully automatic meat smashing machine includes a body 11, the front and rear sides of the body 11 are fixedly provided with two first support plates 44, and the lower side of the body 11 is fixedly provided with four supporting plates. The second support plate 10, two third support plates 15 are fixed symmetrically between the two first support plates 44, and a connecting plate 18 is fixed between the two third support plates 15. The lower side of the body 11 is fixed with a housing 33, the housing 33 is provided with a motor slot 58, and an anvil 35 is arranged between the two first support plates 44, and the anvil 35 is located on the third support plate 15 on the lower side, a transmission mechanism A3 is arranged between the two first support plates 44, a multi-functional automatic meat smashing mechanism A4 is arranged on the lower side of the transmission mechanism A3, and a meat pushing mechanism A4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com