Automatic scribing equipment for shoe processing

A technology of automatic scribing and equipment, applied in the direction of shoemaking machinery, applications, footwear, etc., can solve the problems of insufficient efficiency, difficulty in unifying processing standards, and low efficiency, so as to achieve accurate scribing and improve production efficiency and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

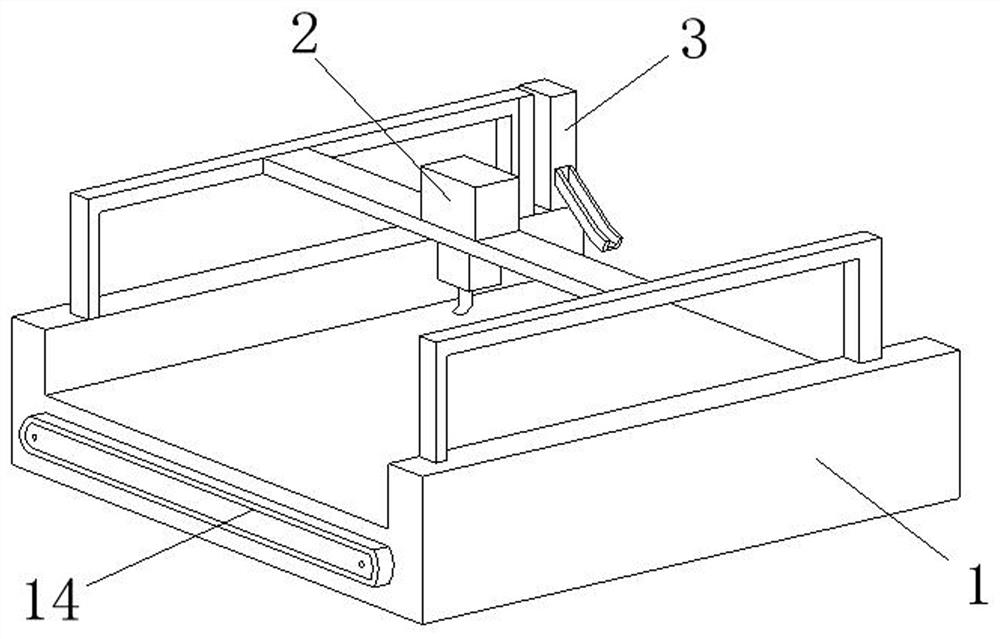

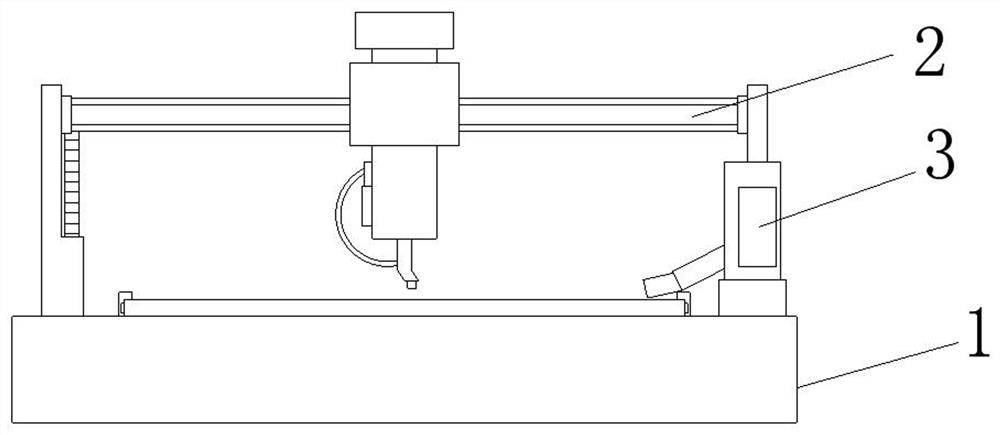

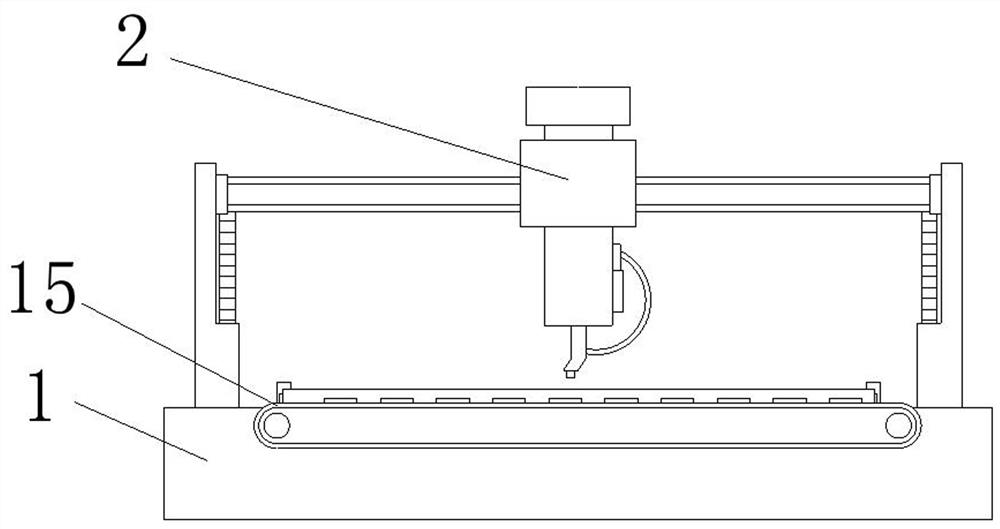

[0025] Embodiment 1, according to figure 1 , Figure 4 and Figure 5 Place the shoe sample that needs to be marked inside the feeder 3 and place it on the pallet 6. The runner 7 rotates, and the transmission rod 8 is used to drive the swing rod 9 to swing. Through the swing of the swing rod 9, the friction wheel is used to 10. Send the shoe sample to the transmission frame 11 by means of frictional force, and at the same time, the round roller group 12 set on the transmission frame 11 is driven by the control box 13 to accelerate the shoe sample, so that the shoe sample falls on the marking machine 2. In the designated position, by accelerating the transmission of the processed shoe samples, the shoe samples can be sent to the conveyor belt set on the marking machine in an orderly manner, so as to realize continuous unloading and improve production efficiency.

Embodiment 2

[0026] Embodiment 2, according to figure 1 , image 3 and Image 6 , the shoe sample that has been marked is conveyed, and falls on the unloading box 16, and is placed between the splints 21. Through the rotation of the motor 17, the shoe sample is clamped by the meshing effect between the gears, and transported by the transmission belt. When the unloading box 16 rotates to the top of the box for collection, the splint 21 is opened by the rotation of the motor 17 and the engagement between the gears, so that the shoe samples fall into the box for collection. The transmission belt, in conjunction with the rotation of the internal motor of the unloading box on the transmission belt, effectively fixes the shoe sample on the unloading box without hindering the unloading, reducing the configuration of production labor, making production more efficient, and reducing labor costs .

[0027] Working principle: Place the shoe sample that needs to be marked inside the feeder 3 and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com