Forest fire extinguishing device

A fire extinguishing device and a forest fire technology, applied in the field of forest fires, can solve the problems of low efficiency of fire extinguishing liquid and low fire extinguishing efficiency, and achieve the effects of high mixing efficiency and waste reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

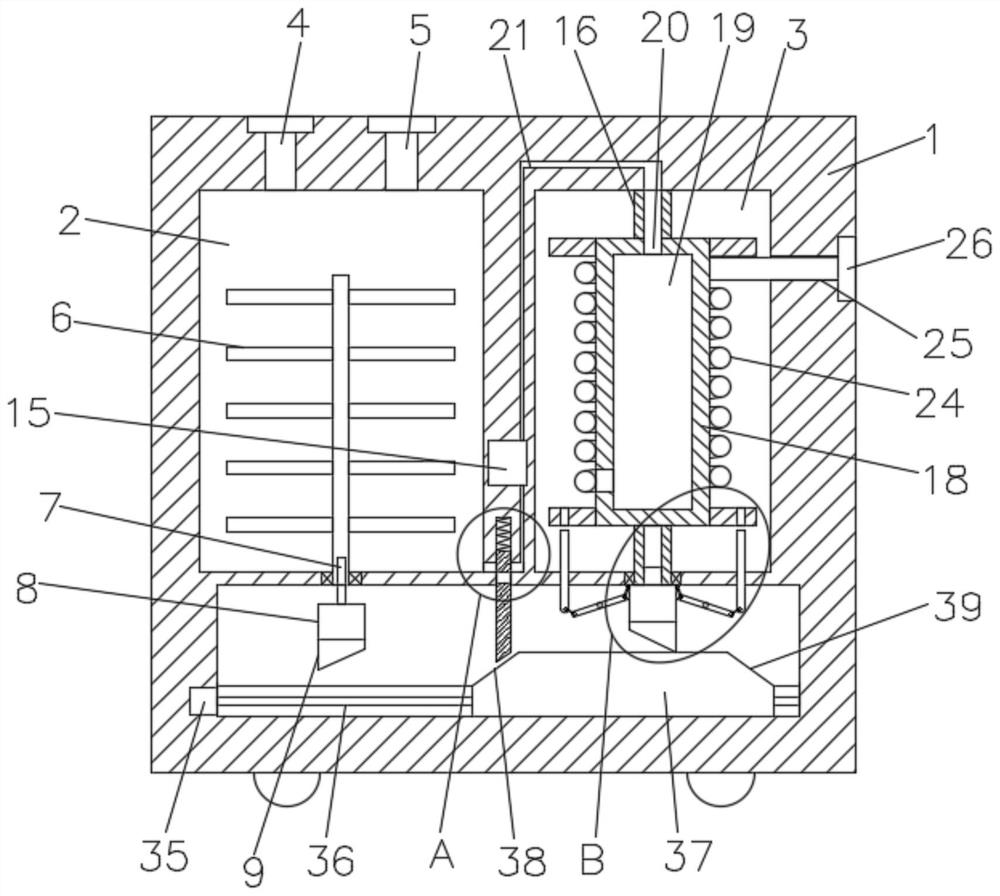

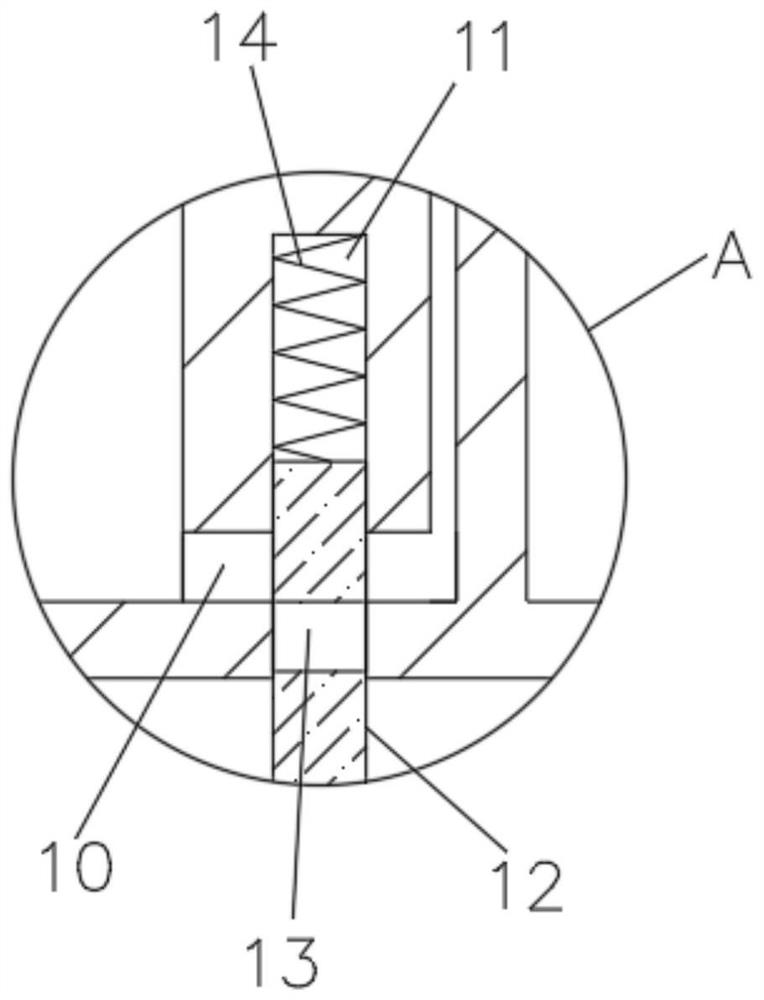

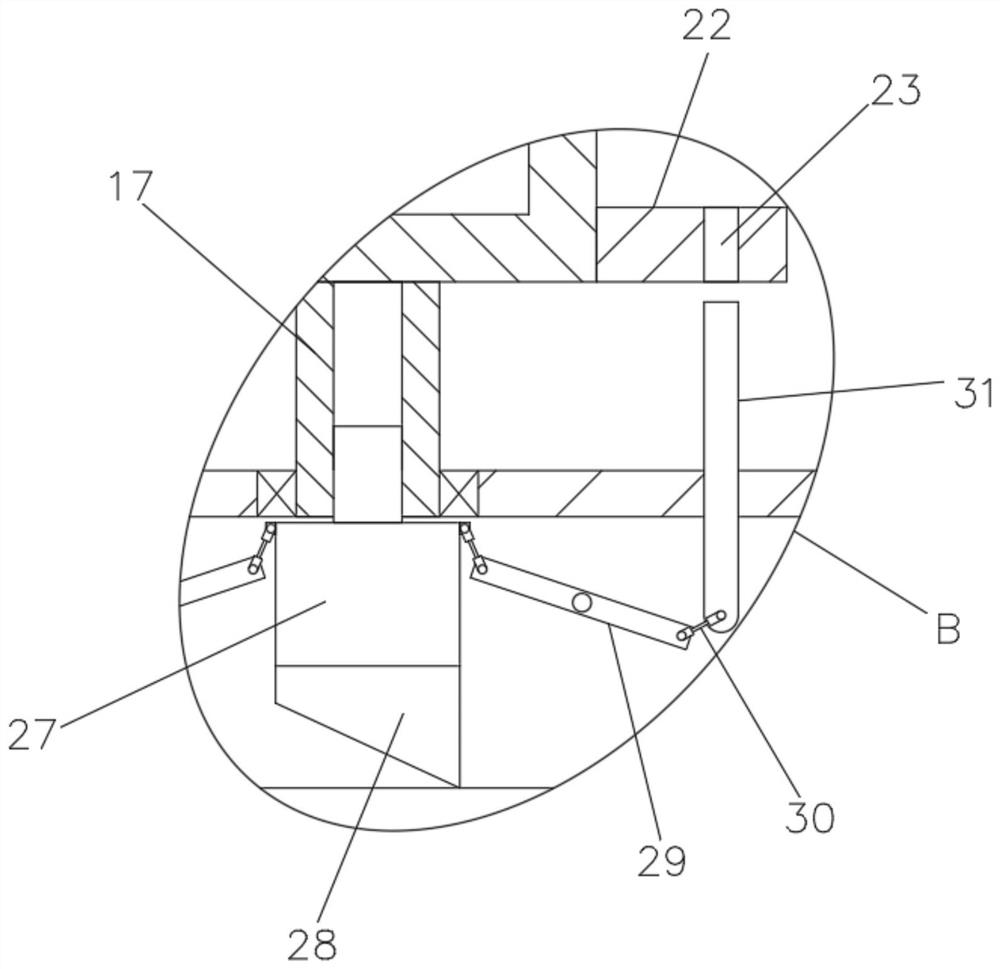

[0023] refer to Figure 1-4 , a fire extinguishing device for forest fires, comprising a body 1, a stirring chamber 2 and a storage chamber 3 are opened in the body 1 in sequence from left to right, the body 1 is provided with a transmission chamber below the stirring chamber 2 and the storage chamber 3, and the stirring chamber 2 There are fire extinguishing agent inlet 4 and fire extinguishing water inlet 5 on the inner top of the inner top, and the inner bottom wall of the mixing chamber 2 is connected with the stirrer 6, and the lower end of the stirrer 6 is set through the interlayer between the stirring chamber 2 and the transmission chamber, and the storage chamber 3 The upper and lower inner walls of the upper and lower drums are respectively rotatably connected with an upper drum 16 and a lower drum 17, and the lower drum 17 runs through the interlayer between the storage chamber 3 and the transmission chamber, and the upper drum 16 and the lower drum 17 are fixedly co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap