High-speed four-channel zip-top can cover detection system

A detection system, cans technology, applied in sorting and other directions, to improve the quality level, reduce labor costs, improve production capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

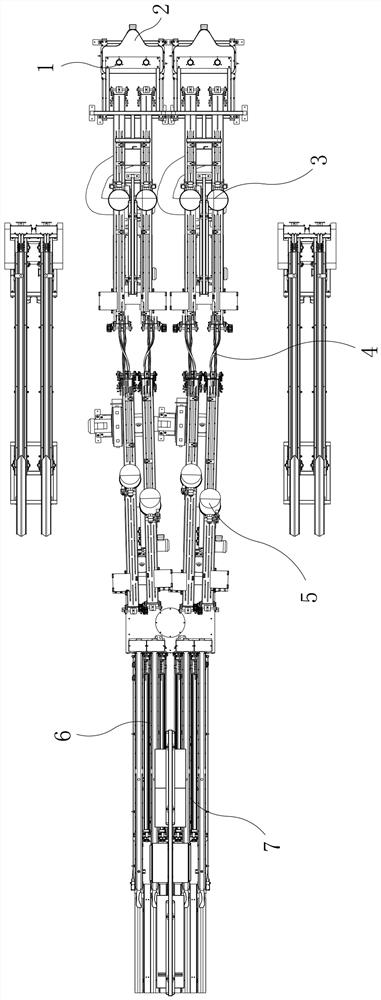

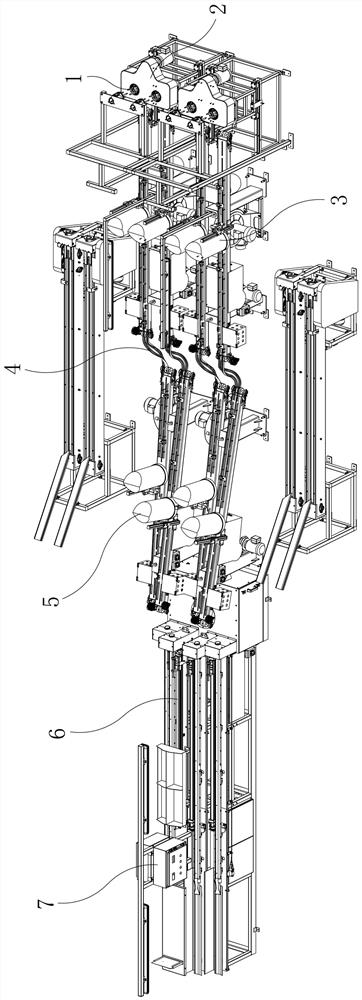

[0024]Such asfigure 1 ,figure 2 As shown, the present invention is a high-speed four-channel easy-open can lid detection system, which includes an unloading mechanism 1, a lid separating mechanism 2, a reverse side detection mechanism 3, a turning mechanism 4, a front detection mechanism 5, a conveying line 6, and a counting packaging device 7.

[0025]The unloading mechanism 1, the lid separating mechanism 2, the back side detecting mechanism 3, the turning mechanism 4, the front side detecting mechanism 5, the conveying line 6, and the counting and packaging device 7 are sequentially connected according to the process steps;

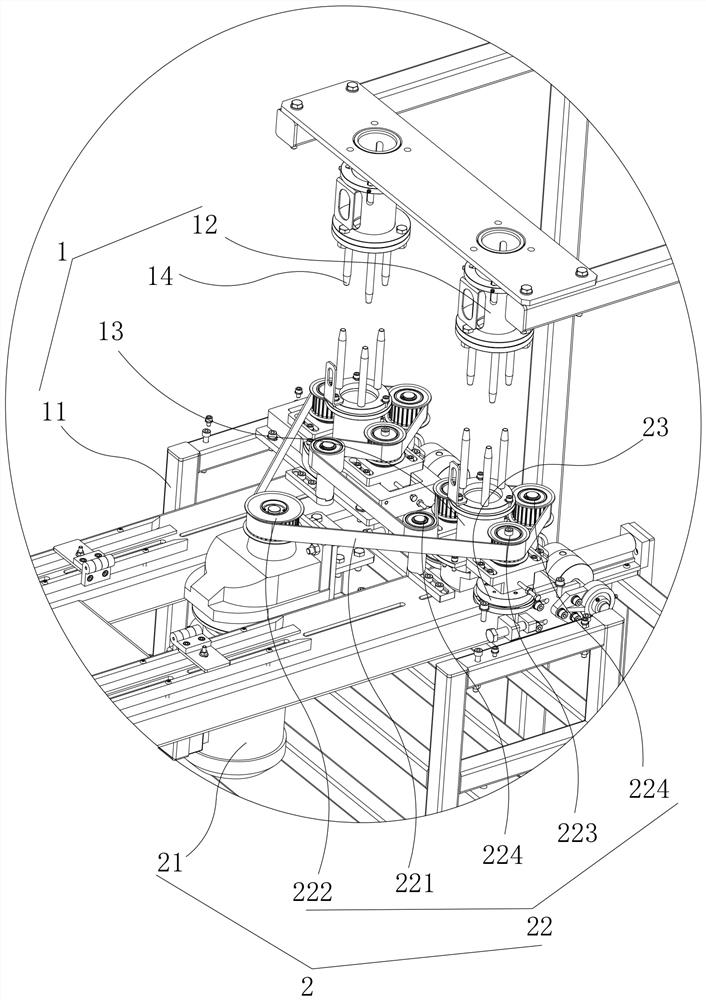

[0026]Such asimage 3 ,Figure 4 As shown, the unloading mechanism 1 includes an unloading frame 11, a top unloading pipe 12, a bottom unloading pipeline 13, and six guide rods 14. The top unloading pipe 12 is installed on the top of the unloading frame 11. The bottom unloading pipe 13 is installed at the bottom of the unloading rack 11 and the bottom unloading pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com