Metal injection molding (MIM) linear type automatic sand blasting machine

A sandblasting machine, linear technology, applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of unstable sandblasting effect, difficult continuous sandblasting operation, unsafe operation, etc. Achieve the effect of reducing the secondary sand removal process, improving production capacity and efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

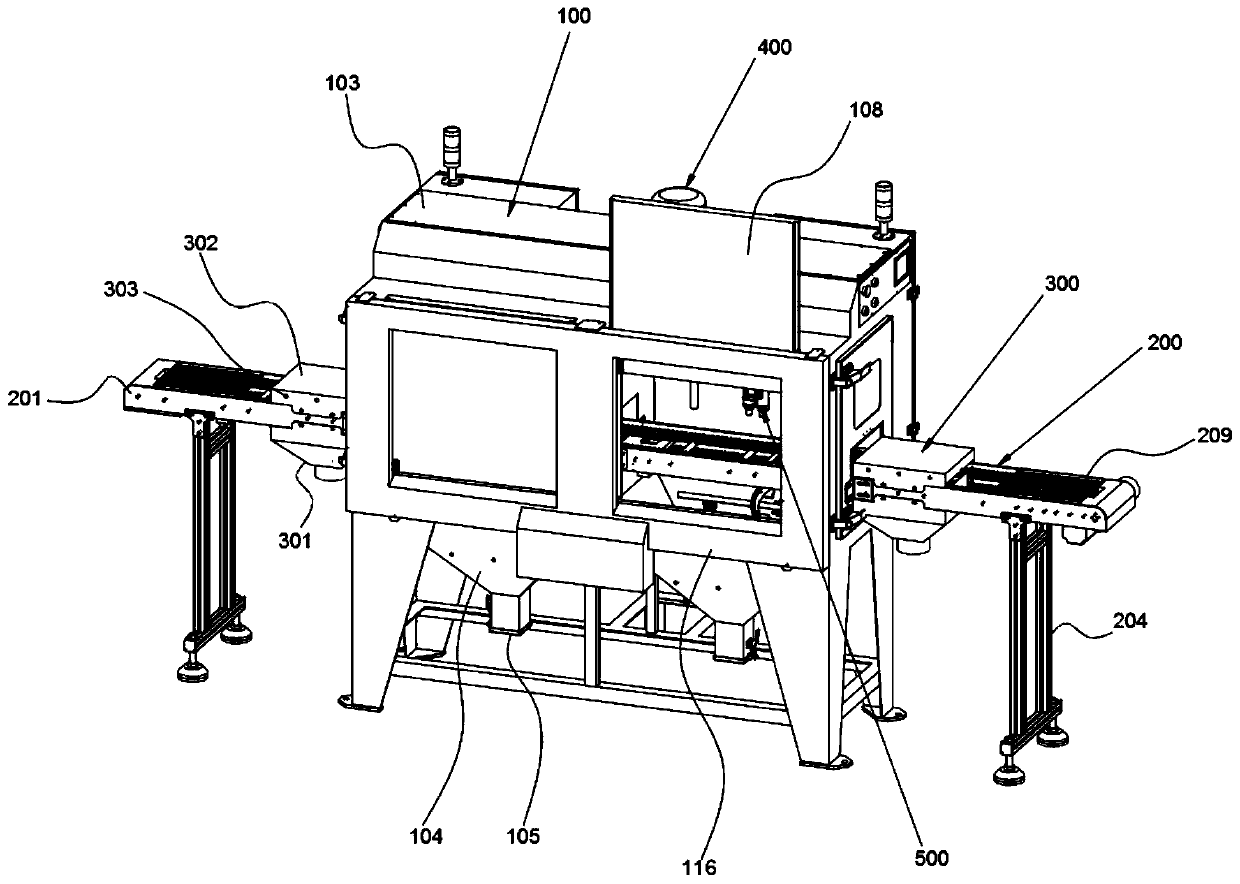

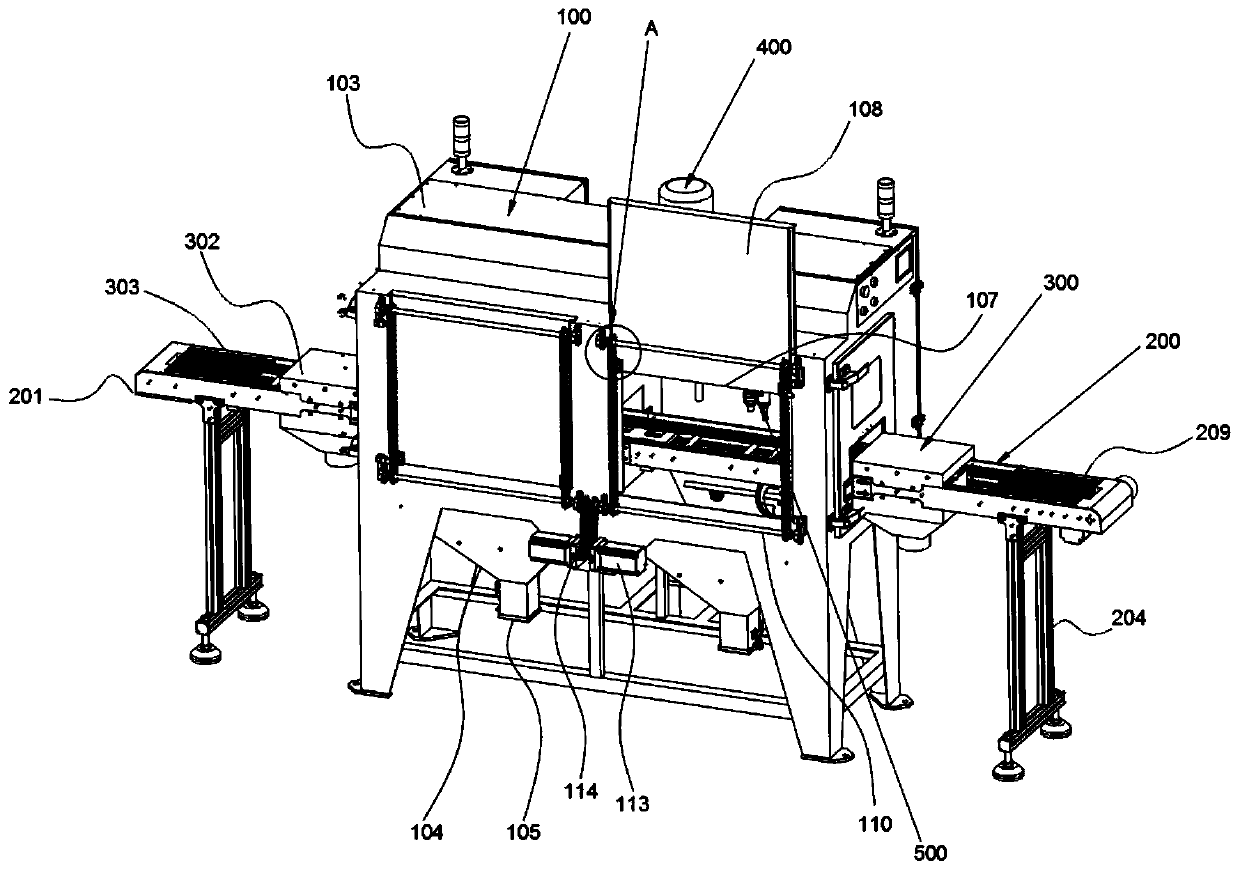

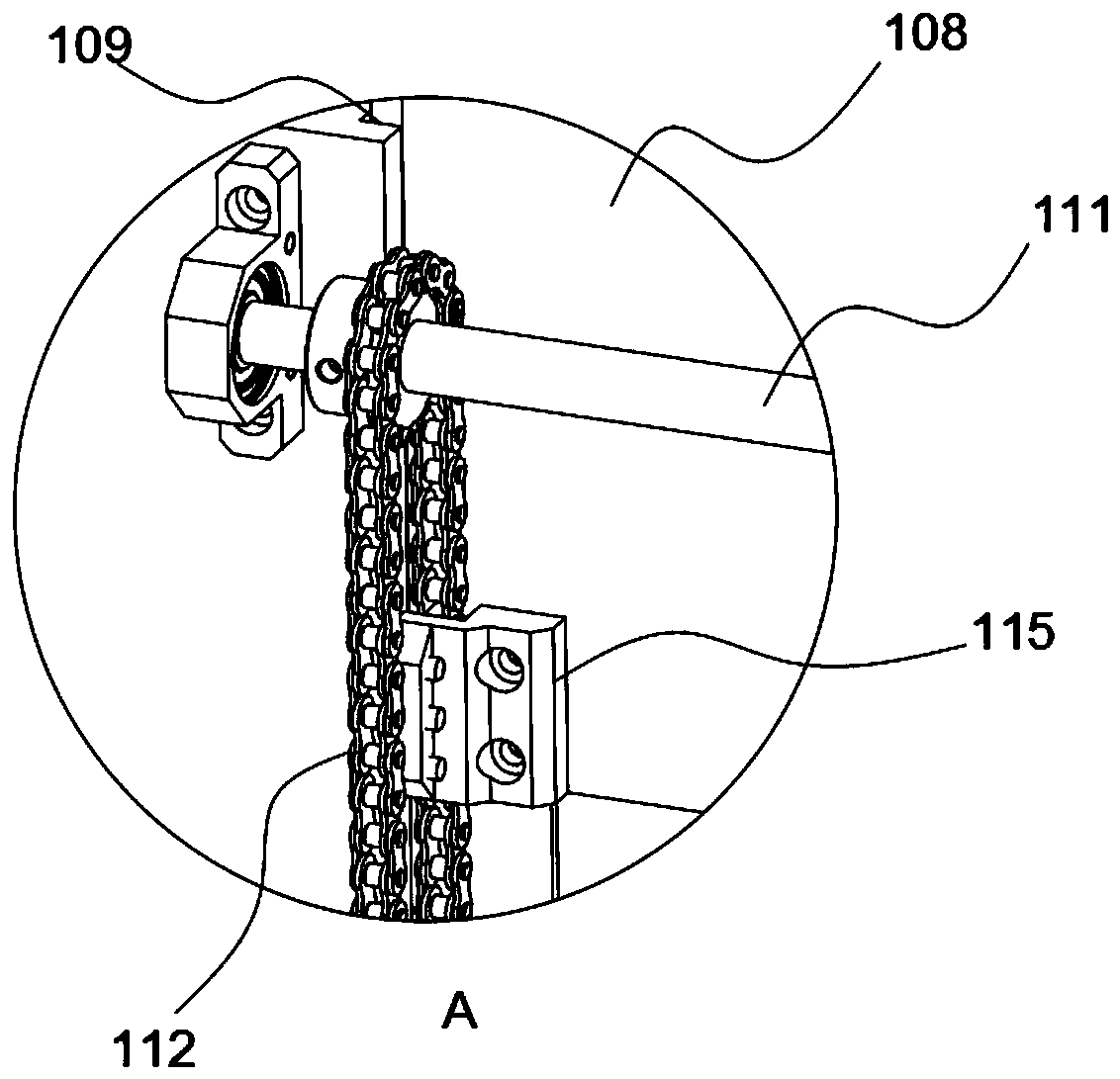

[0036] Such as figure 1 , figure 2 as well as Figure 5 As shown, it includes a main chassis 100, at least one sandblasting chamber 102 located in the main chassis 100, a swing sandblasting device 500 correspondingly fixed in the sandblasting chamber 102, penetrating the main chassis 100 and the sandblasting chamber 102 in the lateral direction The chain conveying device 200, the dust extraction device 400 communicated with the sandblasting chamber 102, and the sandblasting inlet position and the sandblasting inlet position near the sandblasting chamber 102 are respectively located on the chain conveying device 200 and located on the side of the main chassis 100. The air washing device 300 located at the other side of the main chassis 100 near the sandblasting outlet of the sandblasting chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com