Bending system and method for steel column prefabricated part for light steel building

A technology for building steel and prefabricated parts, applied in the field of steel processing, can solve the problems of insufficient bending surface and bending angle, and offset of the bending point of steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

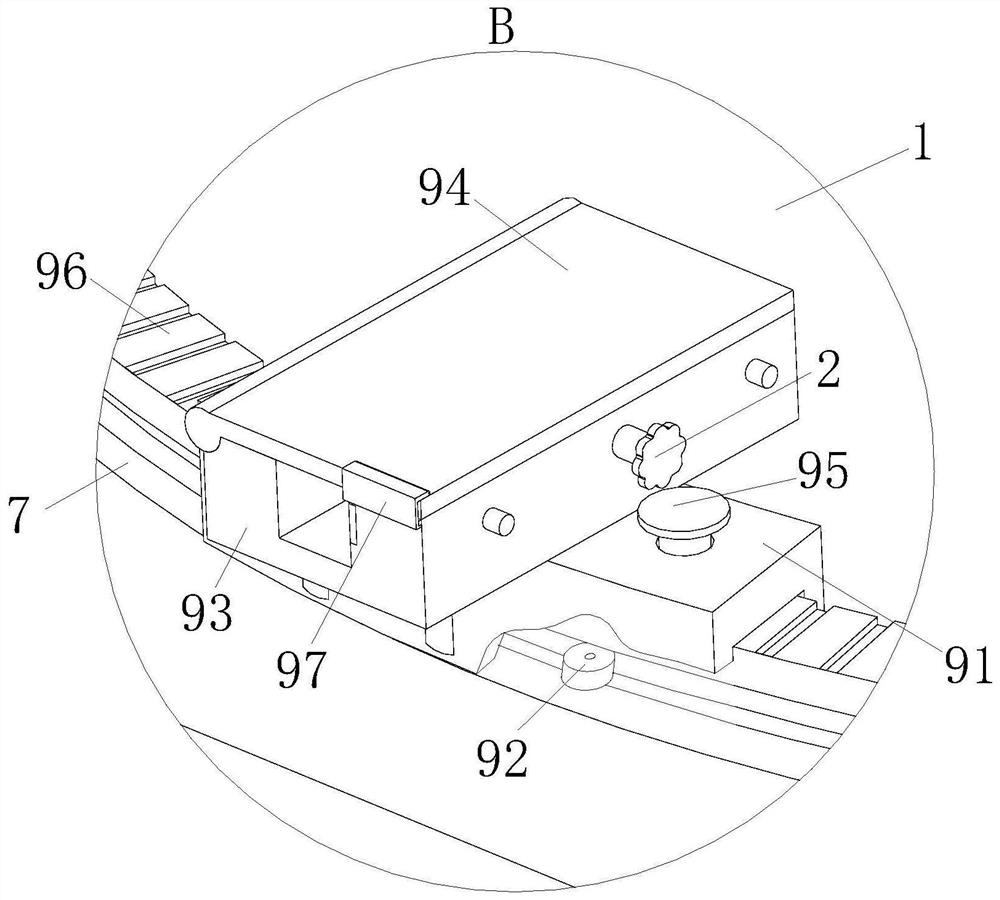

[0027] As an embodiment of the present invention, the top of the workbench 1 is fixedly connected with a fixed slide rail 7 at a position opposite to the bent slide rail 5, and the top of the fixed slide rail 7 is provided with a steel fixing device 9, The steel fixing device 9 includes a fixed sports car 91, a second pulley 92, a second fixing groove 93, a second cover plate 94, a fixing screw 95, a toothed track 96 and a second buckle 97; The top is fixedly connected with a toothed track 96, the top of the fixed slide rail 7 is provided with a fixed sports car 91, the side end wall of the fixed sports car 91 is rotatably connected with a second pulley 92, and the fixed sports car 91 and the fixed slide The rails 7 are slidably matched by the second pulley 92, the wall of the fixed sports car 91 is bolted with a fixing screw 95, the top of the fixed sports car 91 is fixed with a second fixing groove 93, and the second fixing The top of the groove 93 is hingedly provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com