Deformable mechanical arm for high-voltage grounding rod

A ground rod and manipulator technology is applied in the field of deformable manipulators for high voltage ground rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

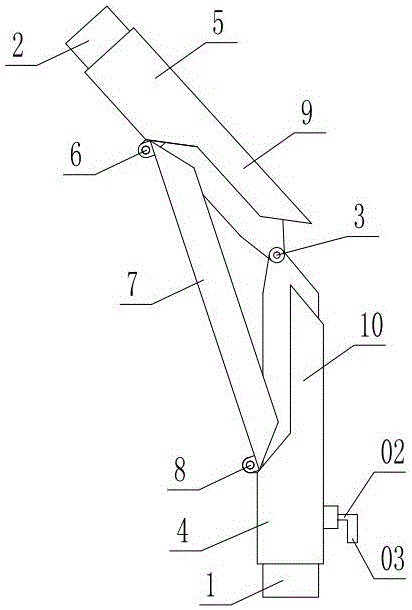

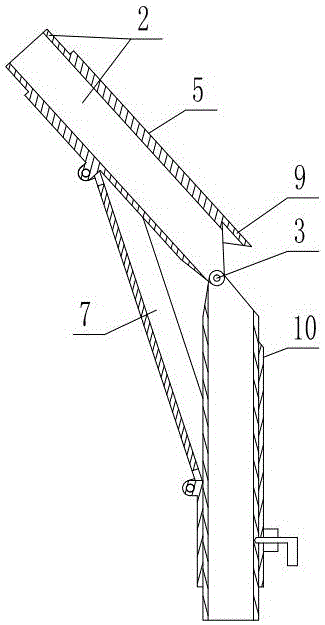

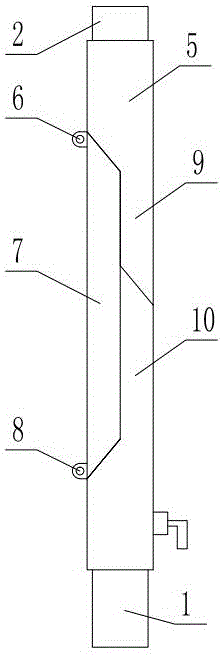

[0020] As shown in the figure, the deformable mechanical arm for high-voltage grounding rods includes a longitudinal tube 1 and a swing tube 2. The upper end of the longitudinal tube is hinged with the lower end of the swing tube through a horizontal inner hinge shaft 3, and the lower tube 4 slides up and down outside the vertical tube. , the outer fixed sleeve of the swing tube is equipped with an upper tube 5, the inner side of the lower end of the upper tube is hinged to a support arm 7 through a horizontal upper hinge shaft, the lower end of the support arm is hinged with the corresponding side of the upper end of the lower tube through a horizontal lower hinge shaft 8, and the lower end of the upper tube An upper extension plate 9 extending downward along the axial direction of the swing tube is fixed on the outer side of the swing, and a lower extension plate 10 extending upward along the axial direction of the longitudinal tube is fixed on the outer side of the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com