Rapid grinding device for steel pipe production

A steel pipe, fast technology, applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problem of difficult adjustment of the fixed position of the inner wall of the clamped steel pipe, so as to improve the convenience of use, ensure the degree of fineness, and improve the versatility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

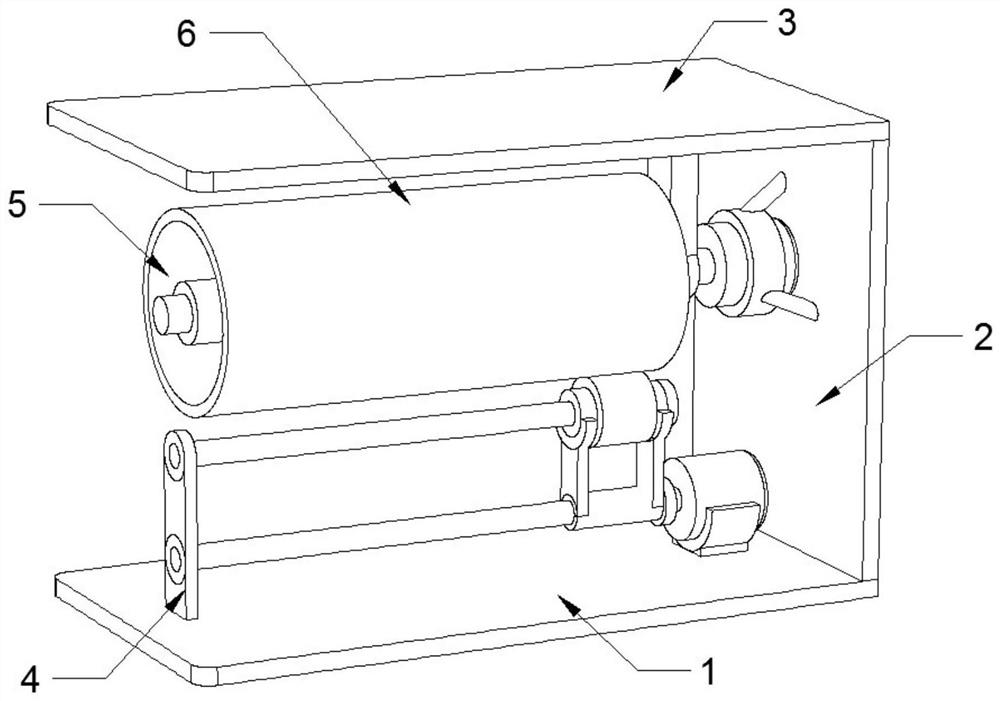

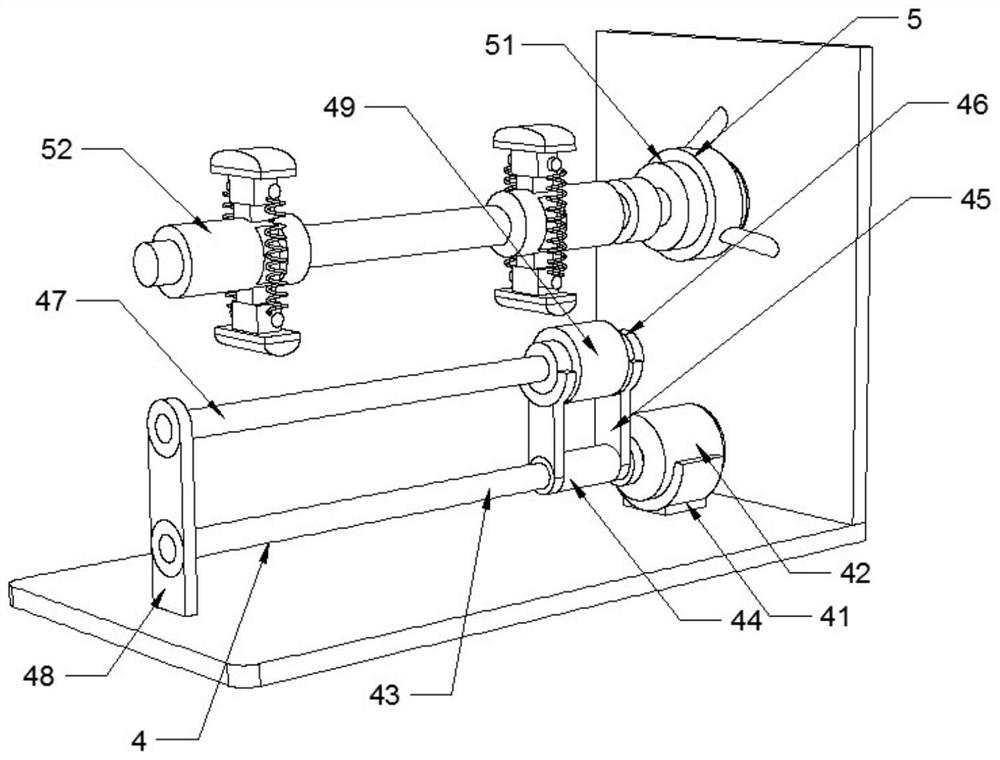

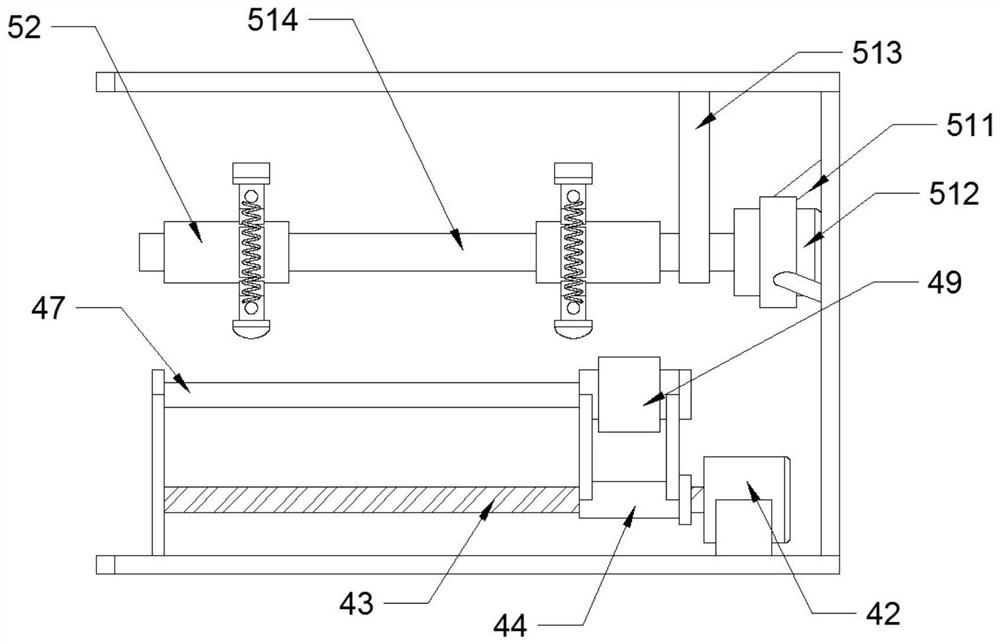

[0025] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The fast grinding device for steel pipe production includes a base plate 1, a grinding mechanism 4 and a clamping device 5, a support 2 is fixedly installed on one side of the base plate 1, a top plate 3 is fixedly installed on the upper surface of the support 2, and a pipe material 6 is movably installed on the upper surface of the base plate 1. The upper surface of the substrate 1 is located on the inner wall of the top plate 3 and is fixedly equipped with a grinding mechanism 4 for sliding and reciprocating movement and grinding. The inner wall of the bracket 2 is located at the corresponding position of the grinding mechanism 4 and is fixedly installed with a clamping device 5 that quickly rotates and clamps the pipe 6 by centrifugal adjustment.

[0026] In the specific implementation process, such as figure 2 , image 3 with Figure 4 As shown, the grinding mechanism 4 inc...

Embodiment 2

[0039] Such as Image 6 As shown, the upper surface of the base plate 1 is located at the corresponding position of the pipe material 6, and the slide rail 410 is fixedly installed, and the two ends of the moving cylinder 44 are fixedly installed with key blocks 411, and the key block 411 is slidably connected with the slide rail 410. The bar 412 drives the key block 411 of the moving cylinder 44 to move on the slide rail 410, which is convenient for the moving cylinder 44 to drive the grinding tool 49 to reciprocate on the outer wall of the pipe material 6 for grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com