Loader, loading system and loading method

A loader and carriage technology, applied in storage devices, transportation and packaging, loading/unloading, etc., can solve problems such as inability to stack goods on the front steps of semi-trailer carriages, and forward shifting of the center of gravity of loading and unloading equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

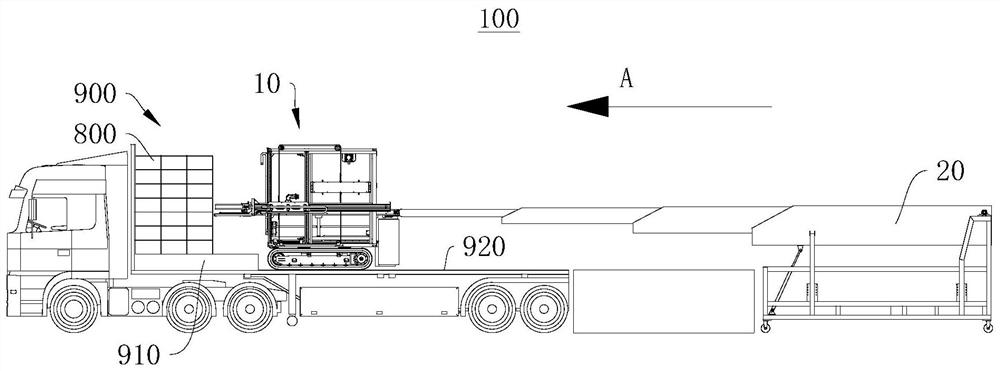

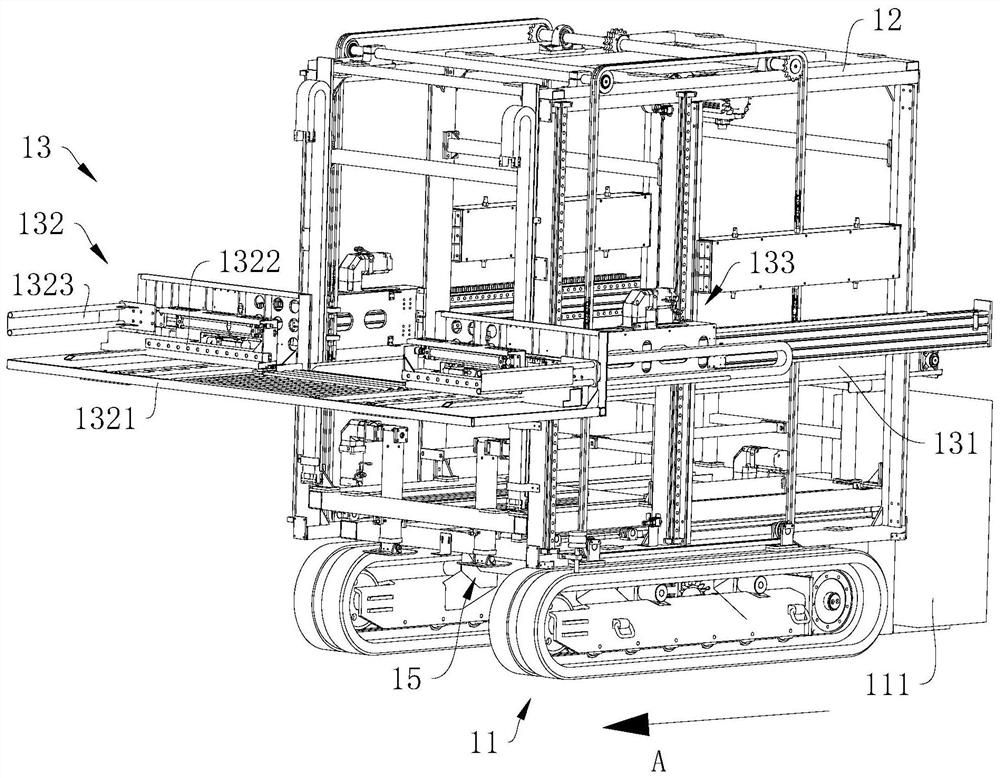

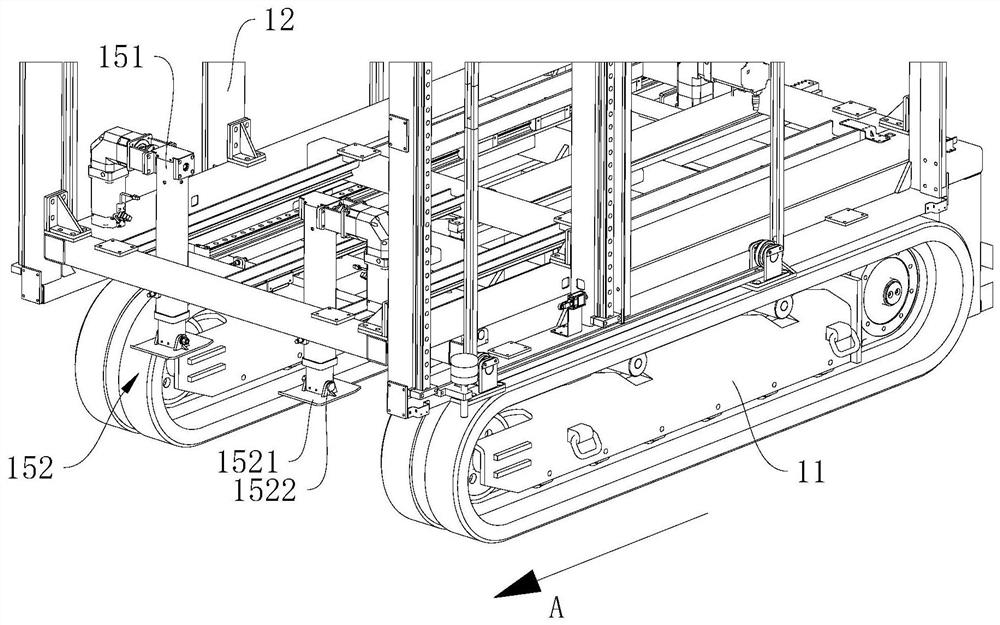

[0037] see figure 1 , figure 1 It is a schematic structural diagram of the vehicle loading machine 10 applied to the vehicle loading system 100 provided by the first embodiment of the present invention. The loading system 100 is performing loading operations in the semi-trailer compartment 900 . And the direction indicated by the arrow A in the figure is the first direction A.

[0038] The first embodiment of the present invention provides a vehicle loading machine 10. The vehicle loading machine 10 has the characteristics of being able to perform vehicle loading operations in a semi-trailer compartment 900 and having high loading stability. The vehicle loading machine 10 can be applied to a vehicle loading system 100 , a storage system or a logistics system, etc. Of course, the vehicle loading machine 10 can also be used independently.

[0039] Taking the vehicle loading machine 10 applied to the vehicle loading system 100 as an example, the vehicle loading system 100 perf...

no. 2 example

[0070] see Figure 8 , Figure 8 It is a schematic flowchart of the vehicle loading method provided by the second embodiment of the present invention.

[0071] The second embodiment of the present invention provides a vehicle loading method, which is applied to the vehicle loading machine 10 of the above embodiment. It also has the characteristics of being able to carry out loading operations in the semi-trailer compartment 900 and having high loading stability.

[0072] It should be noted that the basic principles and technical effects of the loading method provided in this embodiment are the same as those of the above-mentioned embodiment. For a brief description, the part not mentioned in this embodiment can refer to Corresponding content.

[0073] The loading method includes:

[0074] Step S101: moving the loading frame 12 forward along the first direction A, so that the loading frame 12 extends out of the traveling mechanism 11;

[0075] Step S102: Support the loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com