Feeding system for aerial working platform

A high-altitude work platform and suspension technology, which is applied in the direction of lifting devices, load suspension components, cranes, etc., can solve the problems of low operating efficiency and the lack of decorative plate lifting devices on the high-altitude work platform, so as to achieve small working space and improve work efficiency. Safety, disassembly and assembly are safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

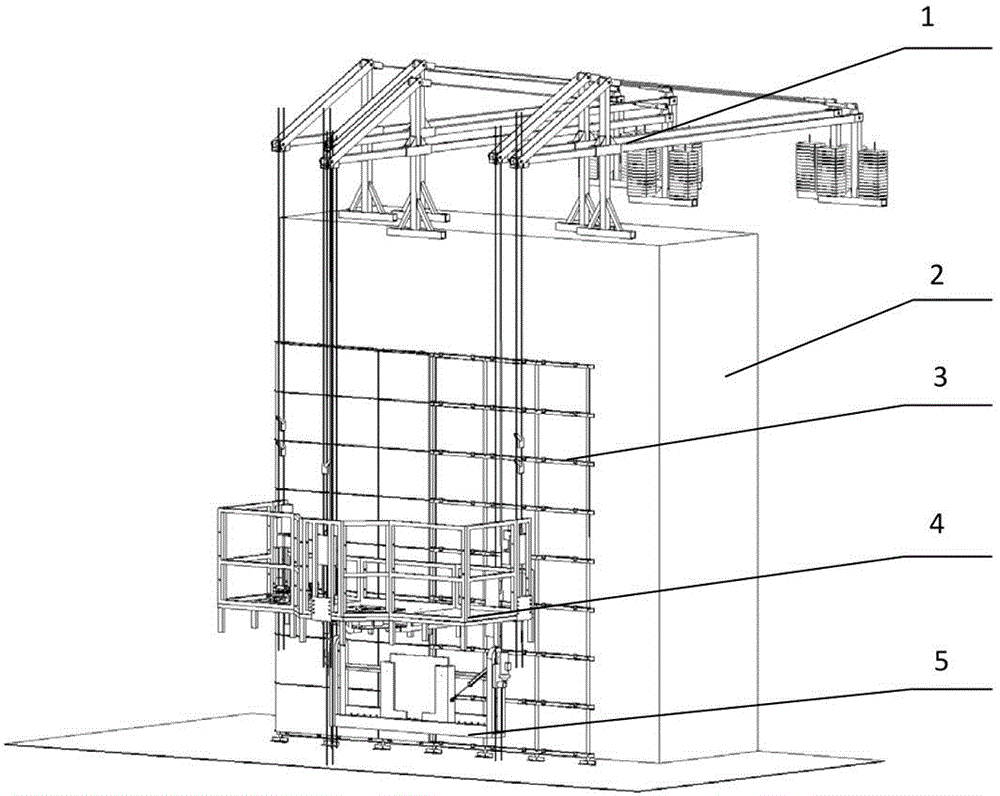

[0019] Such as figure 1 As shown, the working environment of the feeding system of the present invention includes a suspension mechanism 1 , a building 2 , a working facade 3 , an aerial work platform 4 and a feeding mechanism 5 . The suspension mechanism 1 is fixed on the roof of the building 2 through the bolts reserved on the roof, and undertakes the suspension work of the aerial work platform 4 . A sling is installed on the suspension mechanism 1, and hoists are provided on the aerial work platform 4 and the feeding mechanism 5, and the aerial work platform 4 realizes lifting motion through the cooperation of the sling and the hoist. The feeding mechanism 5 is placed between the aerial work platform 4 and the working facade 3 of the building, and is lifted by two hoists.

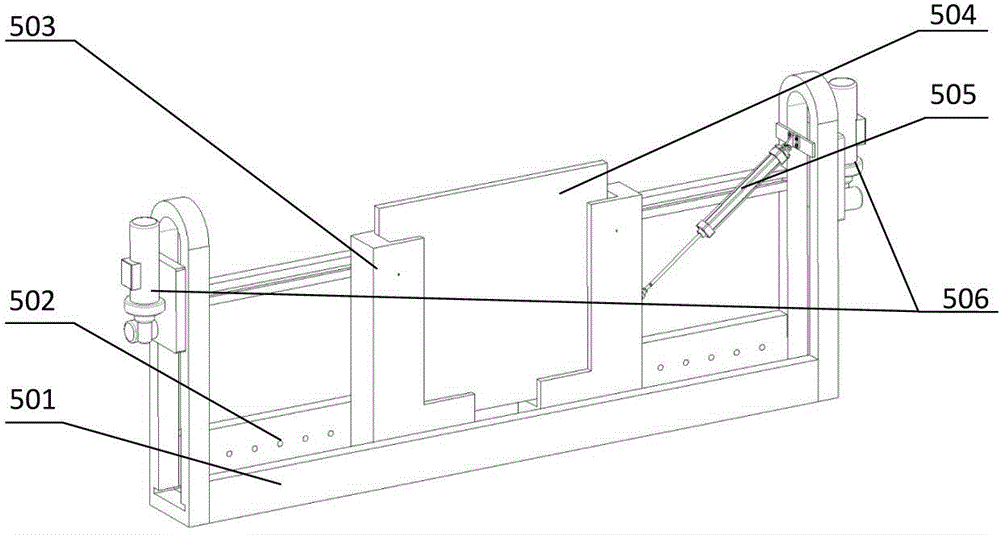

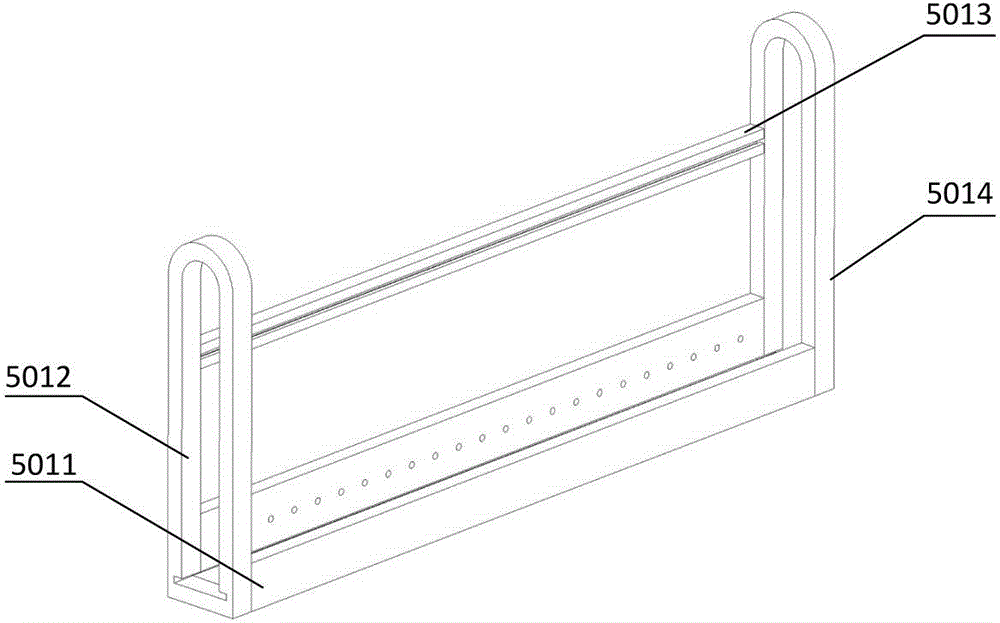

[0020] Such as figure 2 As shown, the feeding mechanism 5 includes a U-shaped lifting frame 501 , a plate clamping mechanism 503 , a push-pull mechanism 505 and a hoist 506 .

[0021] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com