Alloy structural steel wire rod for shaft and preparation method thereof

A technology of alloy structural steel and structural steel, which is applied in the field of alloy structural steel wire rods for shafts and its preparation, can solve the problems of high surface quality requirements of raw materials, difficulties in alloy structural steel wire rods, and unusable hot-rolled wire rods, etc., to achieve The effects of shortening the annealing time, controlling the purity of molten steel, and reducing the annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

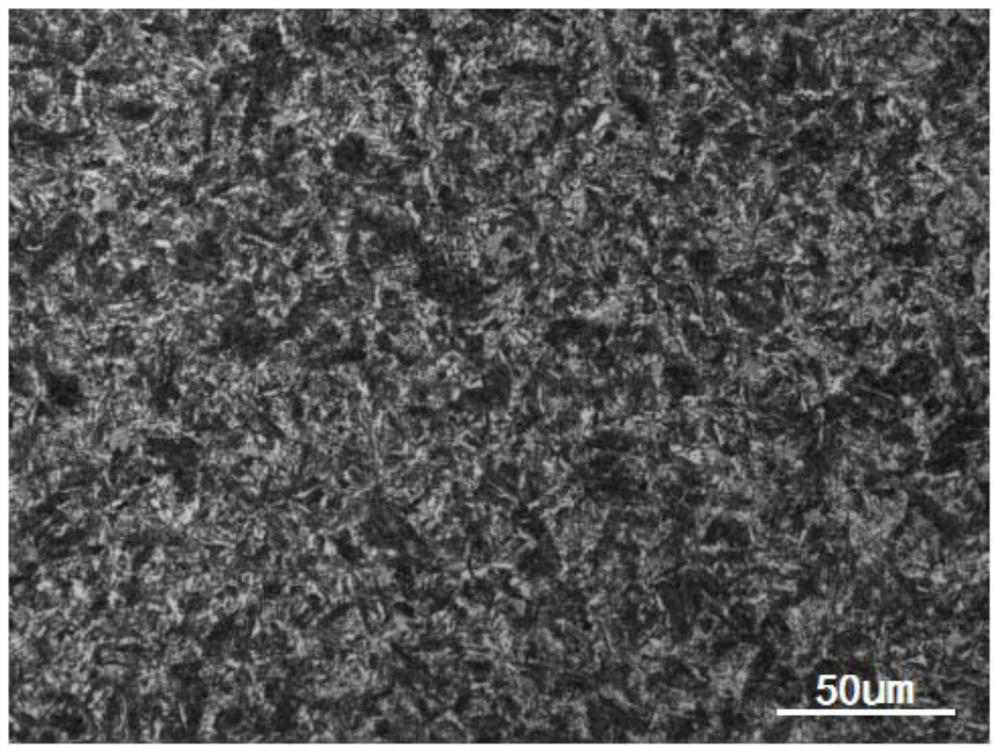

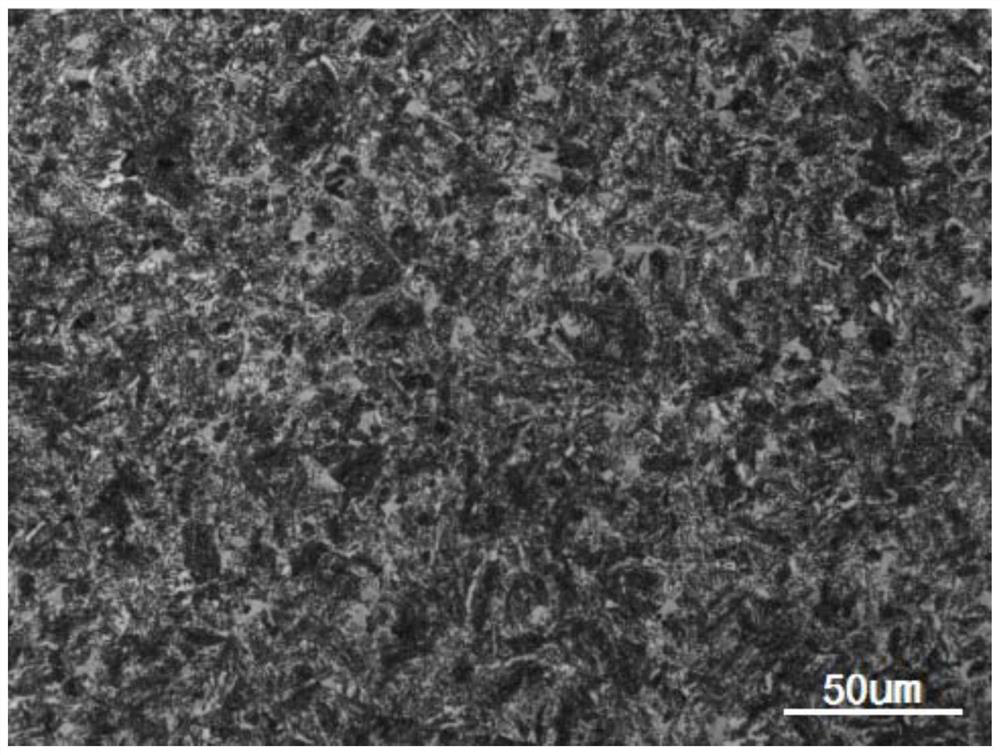

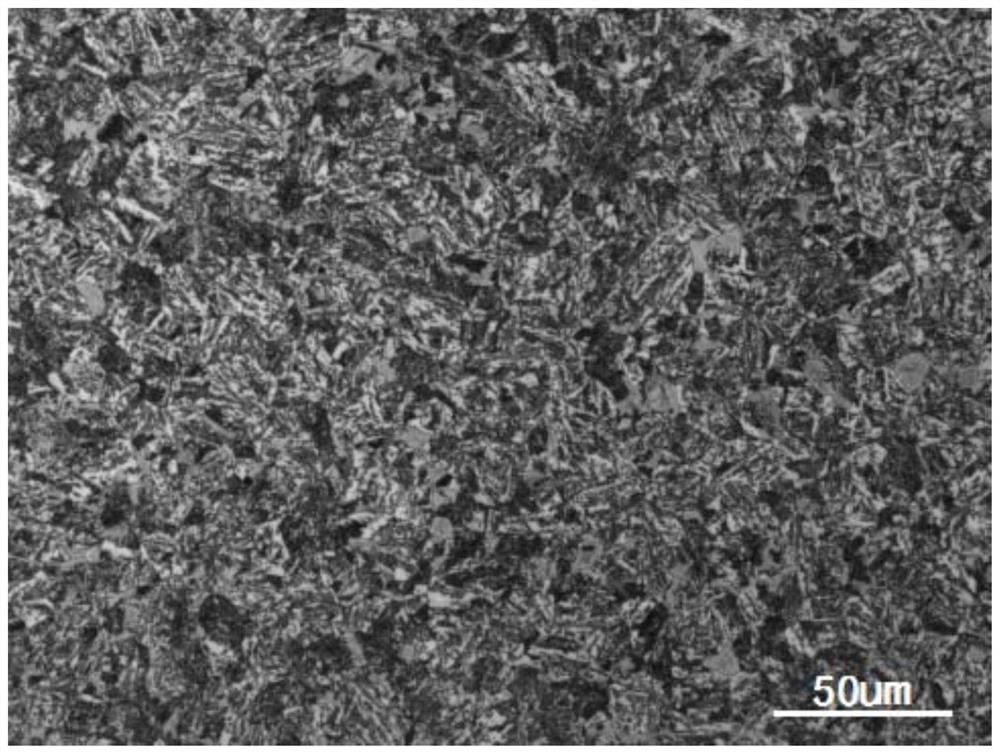

Image

Examples

Embodiment 1

[0043] (1) Converter smelting

[0044] 15t of scrap steel and 5t of pig iron are added to the converter, and 120t of molten iron is added for smelting. [Si]: 0.52%, [P]: 0.06%, and [S]: 0.025% in molten iron. During the smelting process, argon is blown at the bottom for stirring. The converter smelting time 15min tapping, end point [C]: 0.12%, end point [P]: 0.011%, tapping temperature 1640°C, when tapping reaches 30t, start adding 120kg aluminum cake, 205kg ferrosilicon, 1305kg silicon manganese, 1830kg High-carbon ferrochrome, 1650kg nickel plate, 360kg ferromolybdenum, 250kg recarburizer, 500kg lime and 250kg slagging agent. When the steel is tapped to 90t, all the post-furnace feeding is completed. It is 5 minutes, and the argon gas in the ladle is adjusted in time after the tapping is completed to prevent the molten steel from being exposed.

[0045] (2) LF refining

[0046] The molten steel heats up rapidly after LF refining. During the heating process, the argon stirr...

Embodiment 2

[0058] In step (1), add 18t of steel scrap, 6t of pig iron, 115t of molten iron, [Si]: 0.65%, [P]: 0.04%, [S]: 0.020%, end point [C]: 0.10%, end point [P]: 0.009%, tapping temperature 1648°C;

[0059] In step (2), the temperature of molten steel rises to 1610°C, and the LF refining ends;

[0060] In step (3), 50m pure calcium wire is fed, the soft blowing time is 25min, and the soft blowing ends when the molten steel temperature reaches 1565°C;

[0061] In step (4), the continuous casting superheat is 25°C, and the casting speed is controlled at 0.90m / min;

[0062] All the other are identical with embodiment 1.

Embodiment 3

[0064] In step (7), the high temperature section of the intermediate billet is 1080-1120°C, the total heating time is 120min, the rolling start temperature is 980-1000°C, the first three heat preservation covers are opened, and the cover entry temperature is 760-780°C, and the rest are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com