Temperature control assembly, control method and fan coil

A control method and technology of temperature control components, applied in space heating and ventilation, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve uneven temperature distribution in the same space and limited control area of a single thermostat , DDC electric control box installation position and installation distance are limited, etc., to improve the competitiveness of finished products, simple and compact structure, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

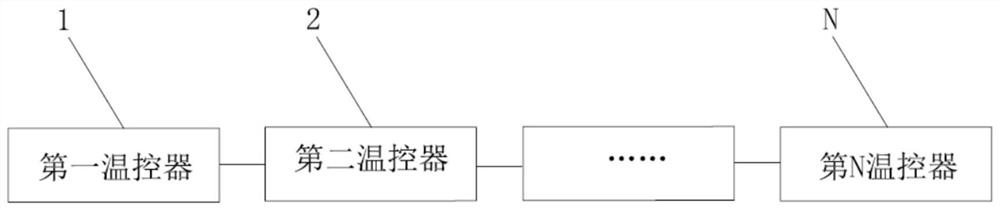

[0033] This embodiment combines figure 1 The temperature control assembly of the present invention will be described in detail.

[0034] The temperature control assembly of this embodiment includes at least two temperature controllers. Preferably, at least two thermostats are connected in parallel with each other, and the at least two thermostats are respectively installed in different control units, so as to respectively detect and control the temperature of the respective control units through the at least two thermostats. The structure of the temperature controller mentioned in this embodiment may be the same as that of the temperature controller commonly used in the prior art, and will not be repeated here. Preferably, the temperature controller in this embodiment can detect the temperature of the control unit where it is located through a temperature-sensing package.

[0035] The temperature control assembly of this embodiment, on the one hand, compared with the DDC ele...

Embodiment 2

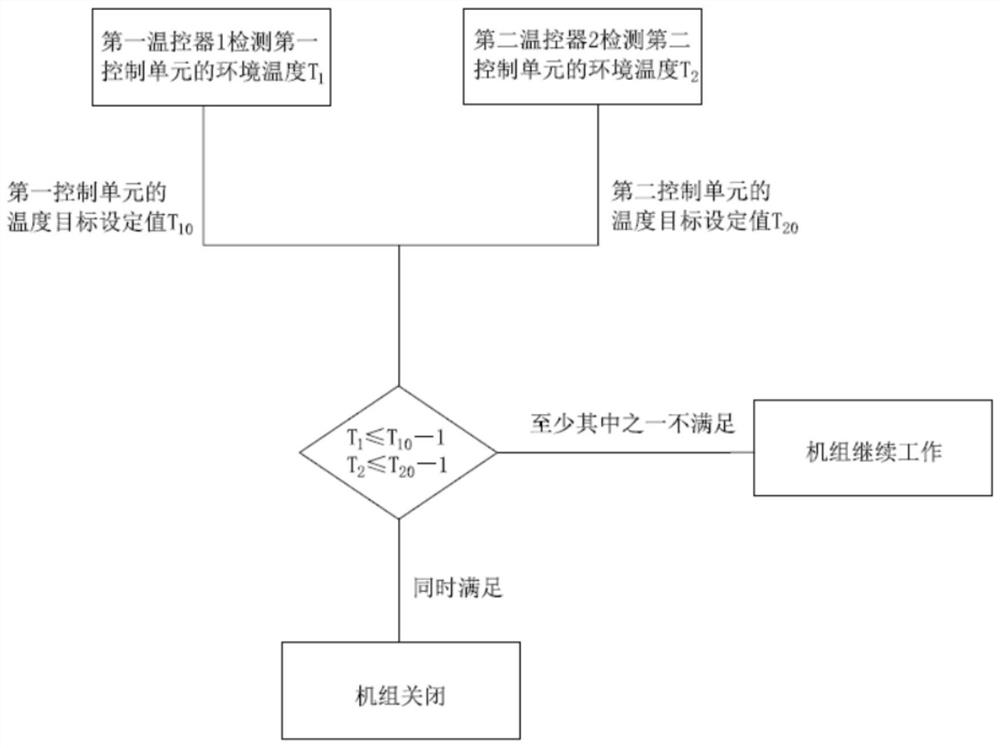

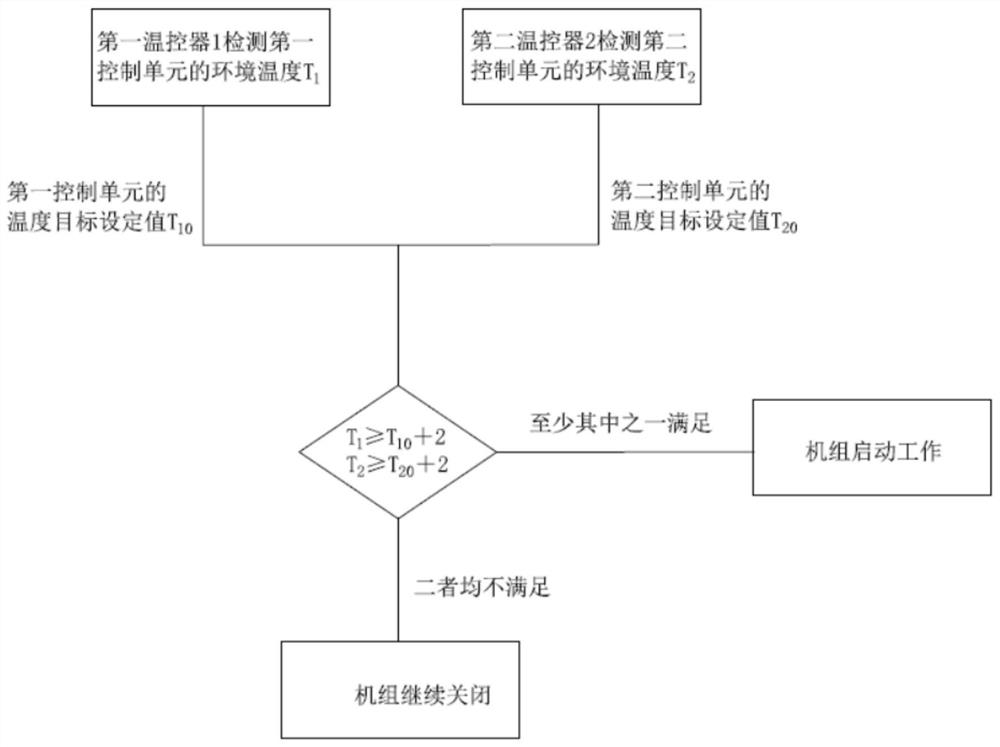

[0039] This embodiment combines Figure 2-5 The control method of the temperature control component of the present invention will be described in detail.

[0040] In the control method of this embodiment, the temperature control component of any technical solution in Embodiment 1 is used to complete the temperature control of the area to be controlled. Preferably, the control method of this embodiment divides the area to be controlled into at least two control units, installs a temperature controller in each control unit, and detects and controls the temperature of the control unit through the temperature controller of the control unit. In the control method of this embodiment, the temperature control component of any one of the technical solutions in embodiment 1 is used to complete the temperature control of the area to be controlled, which can not only increase the installation distance of the temperature control component, but also increase the control area of the thermo...

Embodiment 3

[0055] This embodiment describes the fan coil unit of the present invention in detail.

[0056] The fan coil unit of this embodiment includes the temperature control component of any one of the technical solutions in Embodiment 1. Preferably, the fan coil unit adopts the control method of any technical solution in Embodiment 2 to control the indoor temperature.

[0057] The fan coil unit of this embodiment includes the temperature control component of any technical solution in embodiment 1, and adopts the control method of any technical solution in embodiment 2 to control the indoor temperature, which can not only increase the installation temperature of the temperature control component The distance increases the control area of the thermostat so that the temperature in the same space reaches the preset temperature. It also has the advantages of small installation space and simple structure for the temperature control components, which can improve production efficiency.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com