A Calibration Method of Line Laser and Manipulator

A calibration method and robotic arm technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of unfavorable rapid calibration and strict use conditions, and achieve the effect of reliable calibration results, high degree of automation, and easy search.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

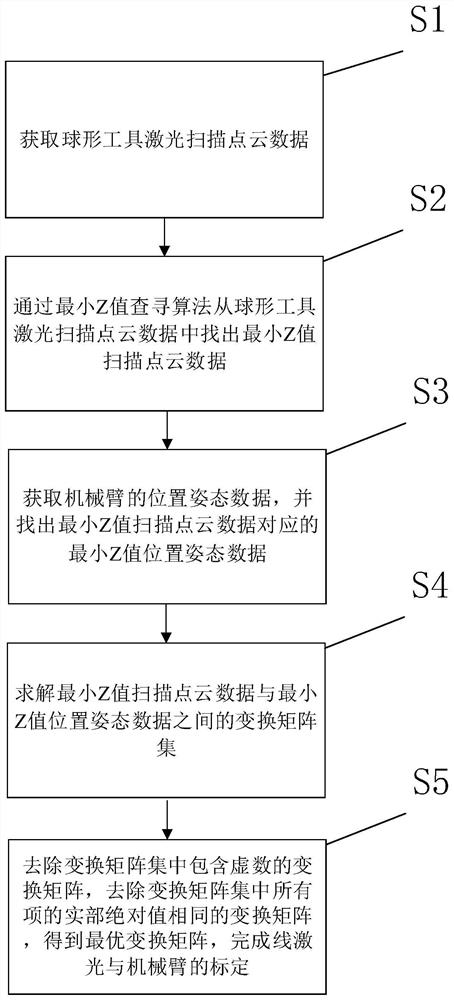

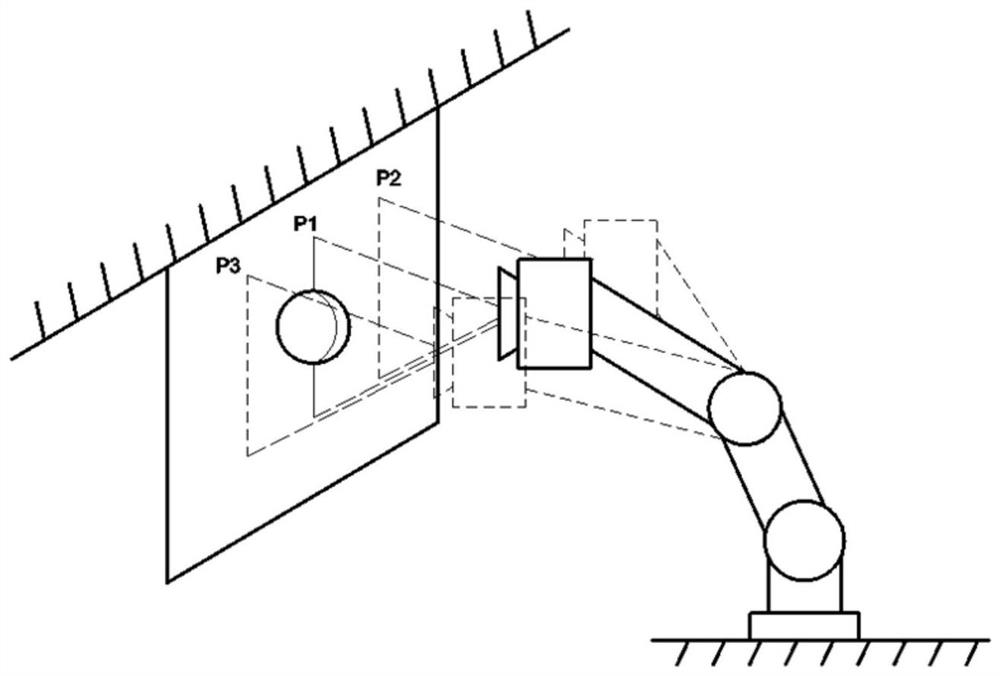

[0038] This embodiment provides a method for quickly calibrating a line laser and a robotic arm based on a spherical tool, such as figure 1 As shown, the method includes the following steps:

[0039] Step S1: obtaining point cloud data of spherical tool laser scanning;

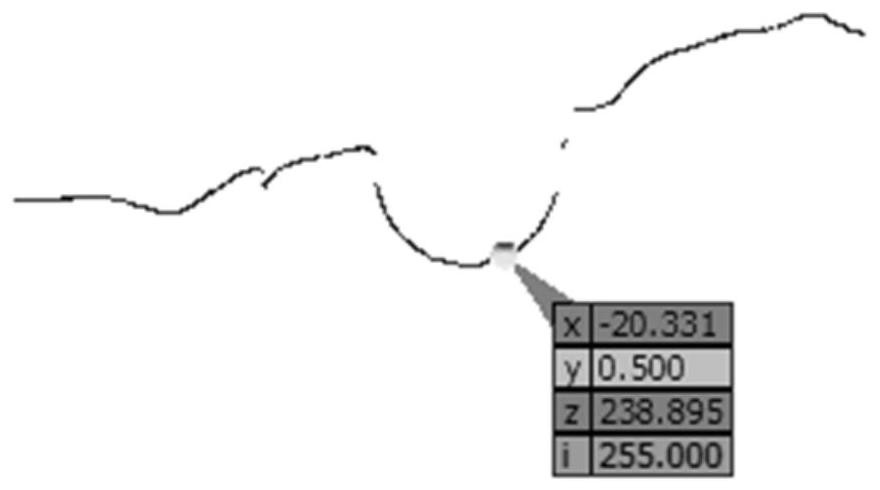

[0040] Step S2: find out the minimum Z value scanning point cloud data from the spherical tool laser scanning point cloud data through the minimum Z value search algorithm;

[0041] Step S3: obtaining the position and attitude data of the robotic arm, and finding out the minimum Z-value position and attitude data corresponding to the minimum Z-value scanning point cloud data;

[0042] Step S4: Solve the transformation matrix set between the scan point cloud data with the minimum Z value and the position and attitude data with the minimum Z value

[0043] Step S5: Remove the set of transformation matrices transformation matrix containing imaginary numbers, remove the set of transformation matrices The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com