Sound pressure calibration method for long linear array cable hydrophone

A calibration method and hydrophone technology, which are applied to instruments, vibration measurement, measurement devices, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of convenient use, low manufacturing cost, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

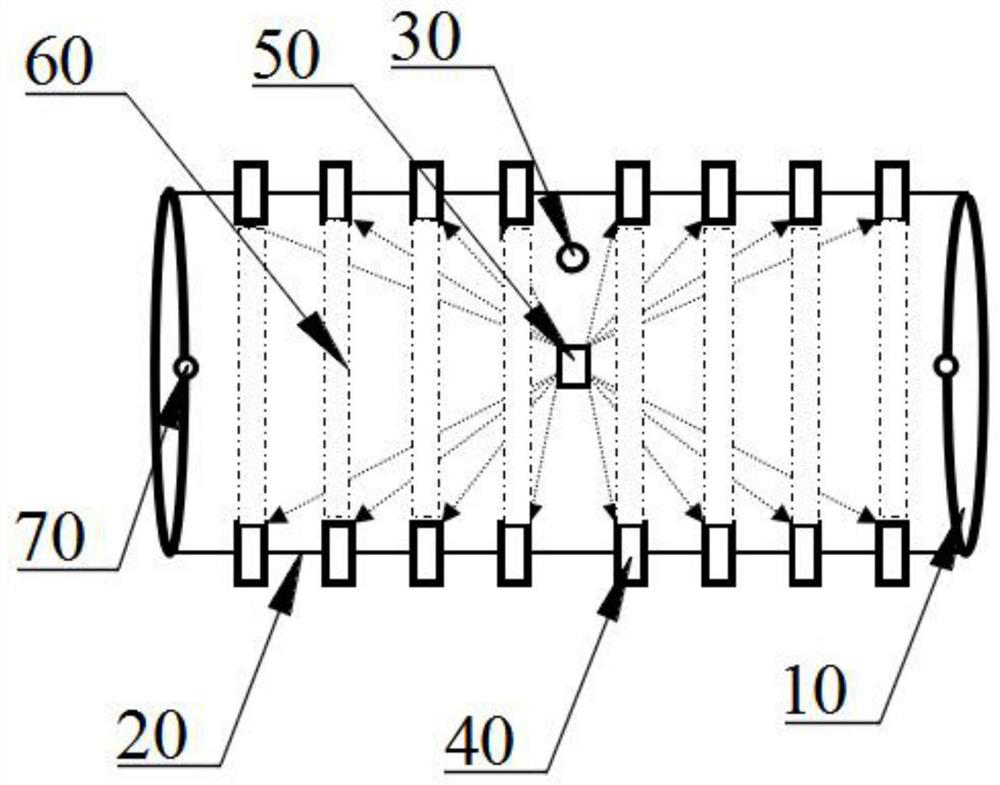

[0027] A method for calibrating the sound pressure of a long line array cable hydrophone, comprising the following steps:

[0028] S1. Coil the long line array cables 60 on the hollow measuring frame, and coil them at a certain distance, while keeping the hydrophone array elements 40 fixed on the relative positions of the array cables 60;

[0029] S2, the low-frequency sound source 50 is vertically suspended and fixed on the hollow measuring frame with nylon ropes, and the circumference of the sound source 50 is tightened with nylon ropes in all directions, so that it does not swing back and forth, and the circumference radiation center of the sound source 50 Be located at the same horizontal position as the hydrophone array element 40 under test;

[0030] S3, install the standard hydrophone 30 at a certain distance from the sound source 50 on the hollow measurement frame, and make the standard hydrophone 30 and the sound source 50 be at the same horizontal position without sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com