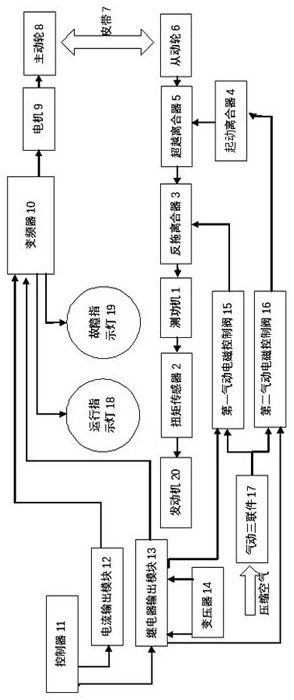

Dynamometer-based anti-drag starting device and its anti-drag control method

A technology of starting device and dynamometer, which is applied in the direction of measuring device, engine test, vehicle test, etc., can solve the problem of increasing the cost of engine test, and achieve the effect of preventing premature damage and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

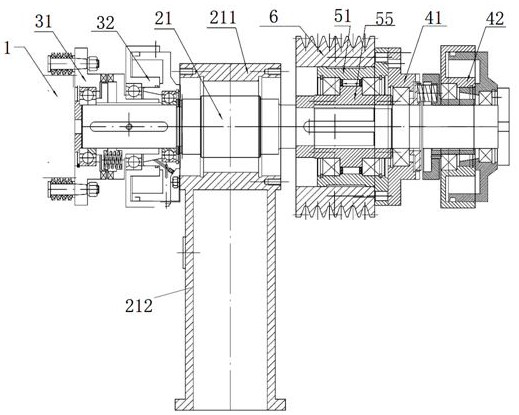

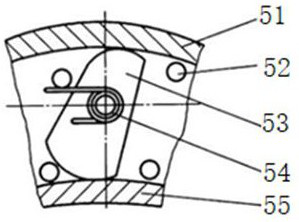

[0171] Embodiment 3: The dynamometer-based anti-drag starting device of the present invention is used to start the ignited engine 20 without using the original starter of the engine 20 .

[0172] In this embodiment, the controller 11 can use the computer equipment of the prior art, and is equipped with control software corresponding to the engine test bench. Grid I-7060D, the model of the current output module 13 is ICP DAS I-7024, the model of the motor 9 is 1PH7224-2MF00-0AA3, the model of the inverter 10 is ASC8000-17-0140-3+N671+L502+K458, pneumatic The model of triplet 17 is AC2000-02, the model of torque sensor 2 is KISTLER 4542AN1C, the model of starting clutch 4 is QLY02, the model of anti-drag clutch 3 is QLY01, the model of overrunning clutch 5 is CKA140, the model of dynamometer 1 is It is Yike WE51 hydraulic dynamometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com