Plane symmetric aircraft hang-off load calculation and strength check method

A technology of strength checking and load calculation, which is applied in the direction of instruments, design optimization/simulation, special data processing applications, etc., and can solve problems such as introduction, error, and wrong calculation results of hanging point loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0154] The present invention will be described in further detail below in conjunction with the accompanying drawings.

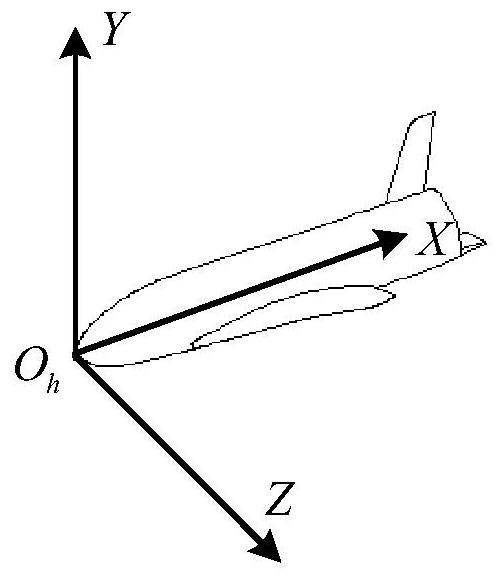

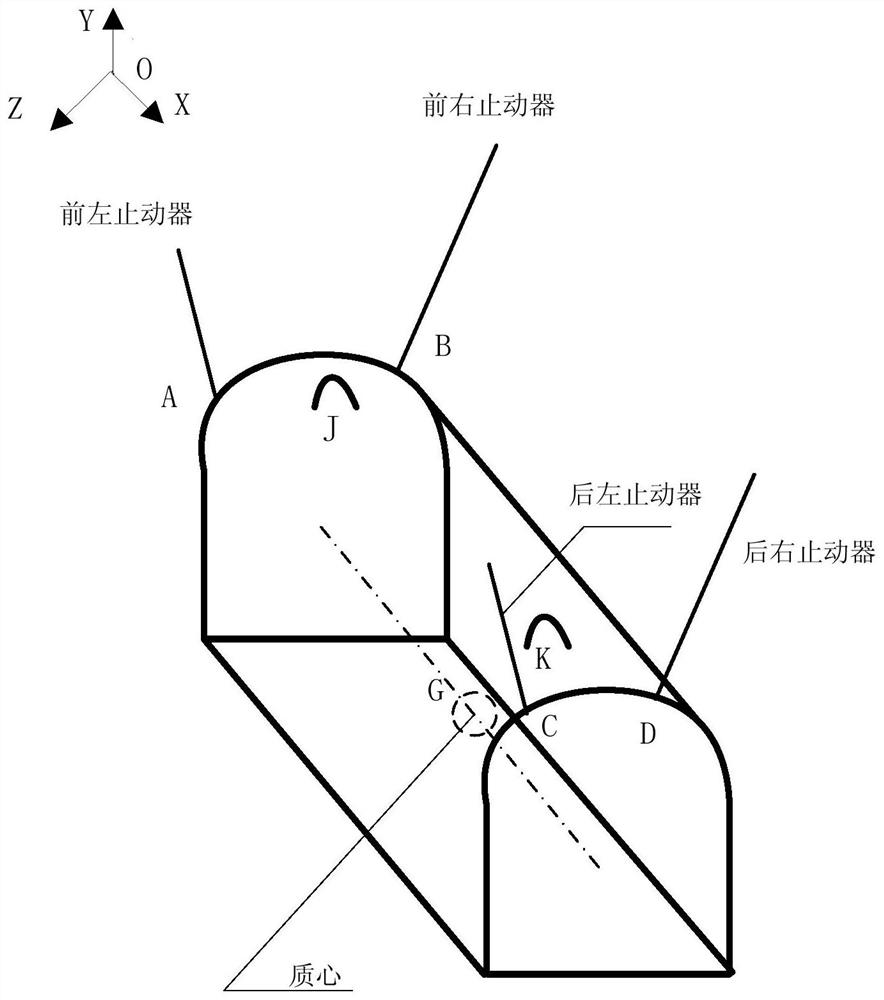

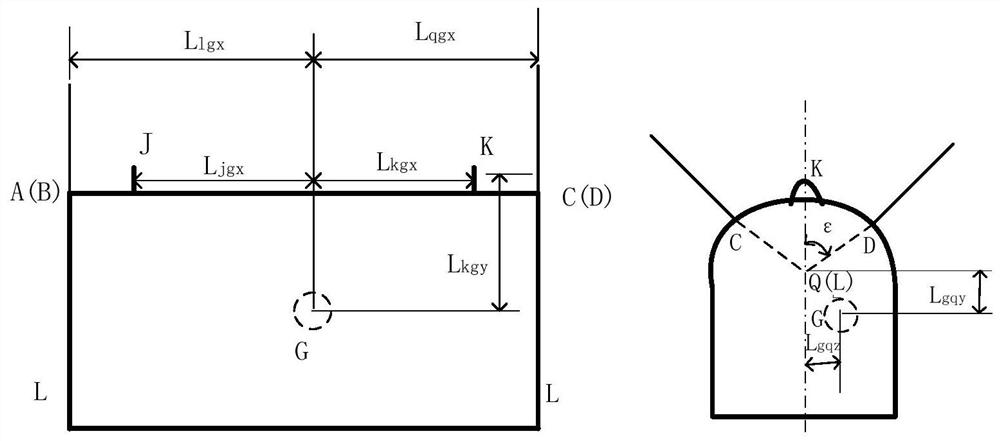

[0155] The schematic diagram of the coordinate system of the suspended object of the plane symmetric aircraft of the present invention is as figure 1 As shown, the invention has two steps. The basic equations of inertial, aerodynamic loads, and hanging point loads are given in the form of vector calculations, and the analytical expression of the hanging point loads for the calculation of the hanging point loads of the plane-symmetrical aircraft is established, and the hanging point loads are obtained. The initial solution and final solution of the load; considering the influence of the lateral force, a high-precision strength check method for the lifting lug and presser foot area is established. figure 2 Schematic diagram of lifting lug and stopper.

[0156] 1 Load calculation of hanging point (including hanging point and presser foot point)

[0157] 1.1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com