Sensing assembly, manufacturing method thereof and battery module

A manufacturing method and component technology, applied in the field of battery modules, can solve the problems that the sensing line cannot be connected to the terminal or the sensing pin, the bending part 14a sticks to the designated position, and is difficult to automate, so as to improve the convenience of manufacturing, Improvement of assembly convenience and economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

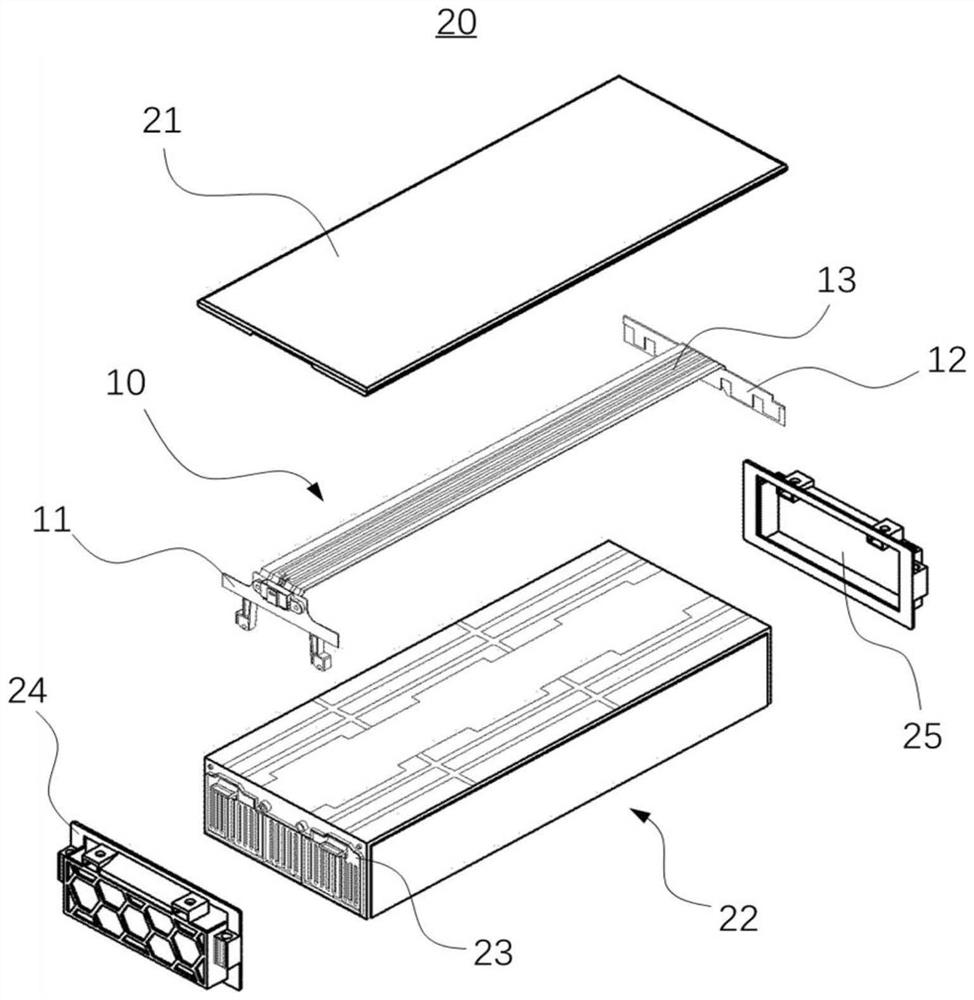

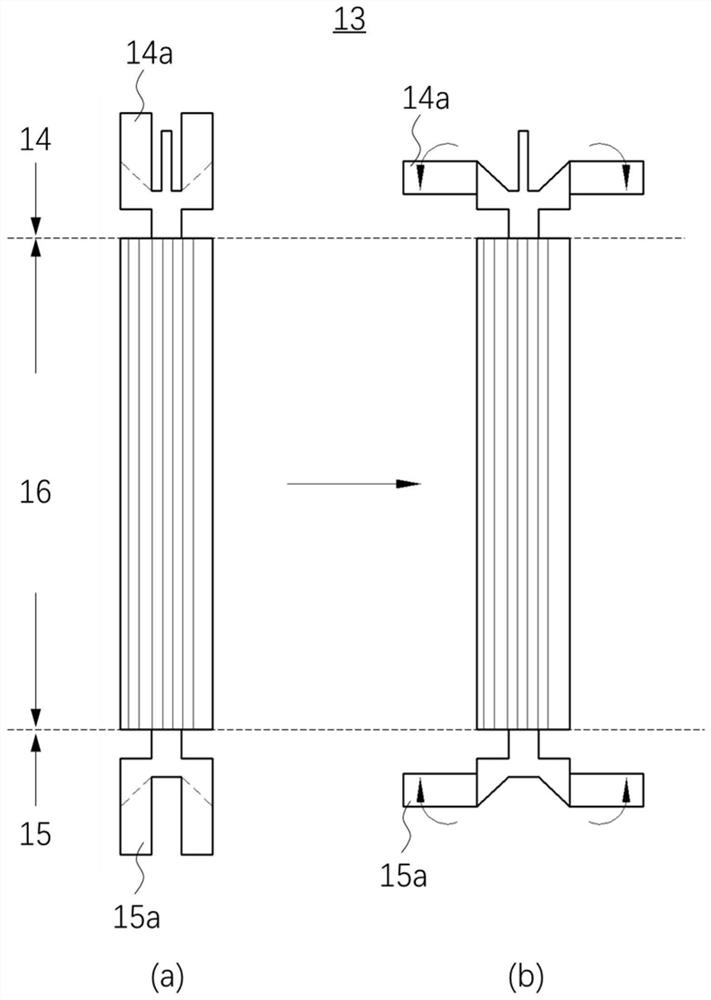

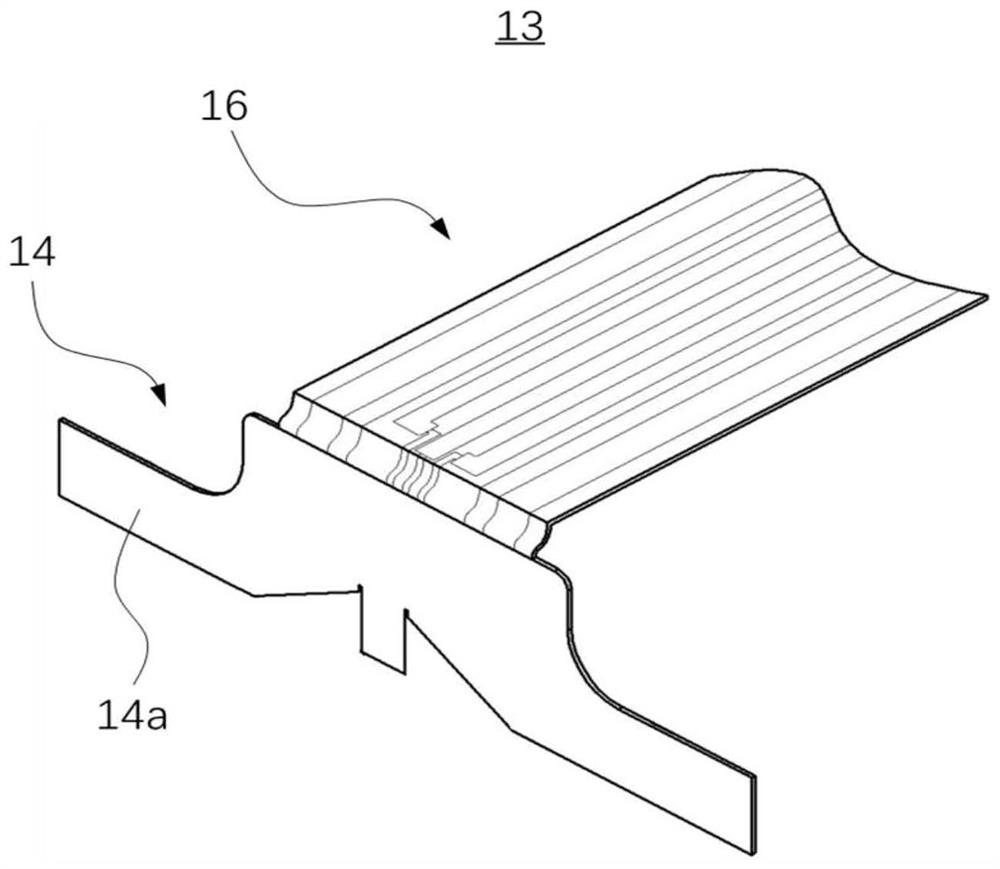

[0077] Hereinafter, the sensing assembly and the battery module including the sensing assembly according to the present invention will be described in detail with reference to the accompanying drawings. The drawings are only provided as examples to fully convey the technical idea of the present invention to those skilled in the art, and the present invention is not limited to the drawings presented below, and can be embodied in other ways.

[0078] Figure 5 The plane of the sensing assembly according to one embodiment of the present invention is schematically shown.

[0079] Such as Figure 5 As shown, the sensing assembly according to one embodiment of the present invention may include a first substrate 100 , a second substrate 200 and a sensing pin 300 .

[0080] The pair of first substrates 100 are spaced apart from each other and formed of a rigid printed circuit board (Rigid Printed Circuit Board, hereinafter referred to as RPCB). Such as Figure 5 As shown by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com