Monitoring system for manual measurement and detection operation

A monitoring system and manual technology, applied in the direction of electrical operation teaching aids, closed-circuit television systems, TV system components, etc., can solve the problems of non-monitoring of the standardization of operation and testing equipment, so as to improve product testing efficiency and prevent product errors. Judgment, reduce the effect of management workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

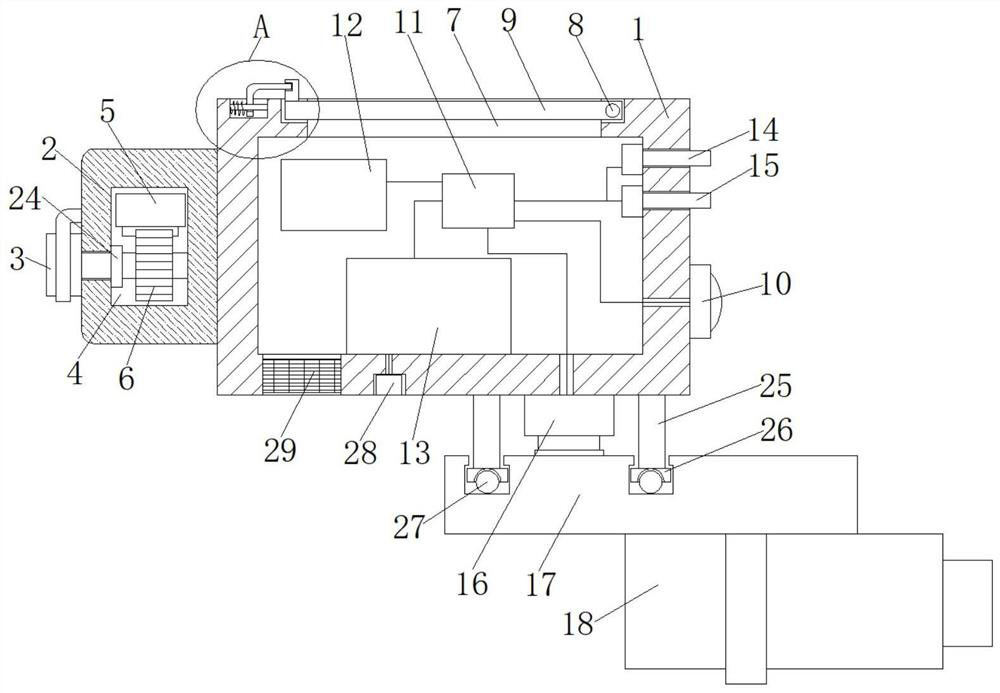

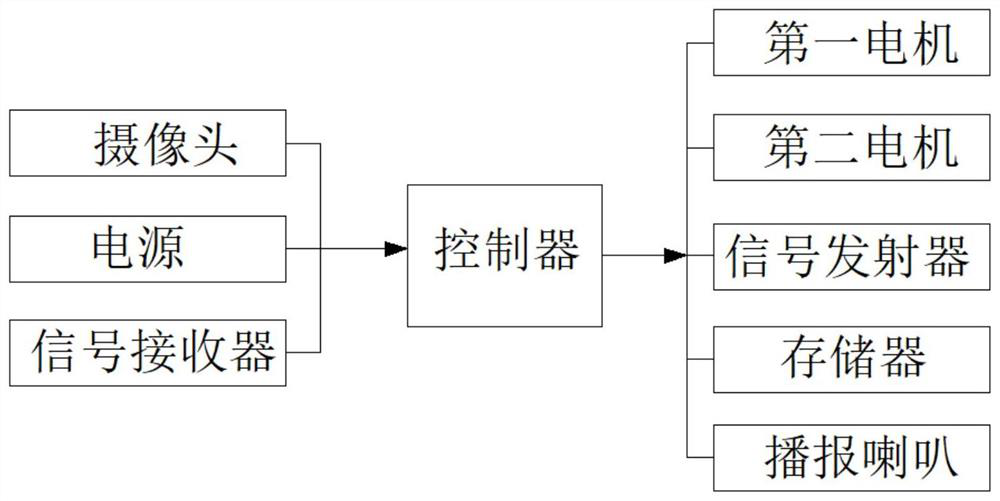

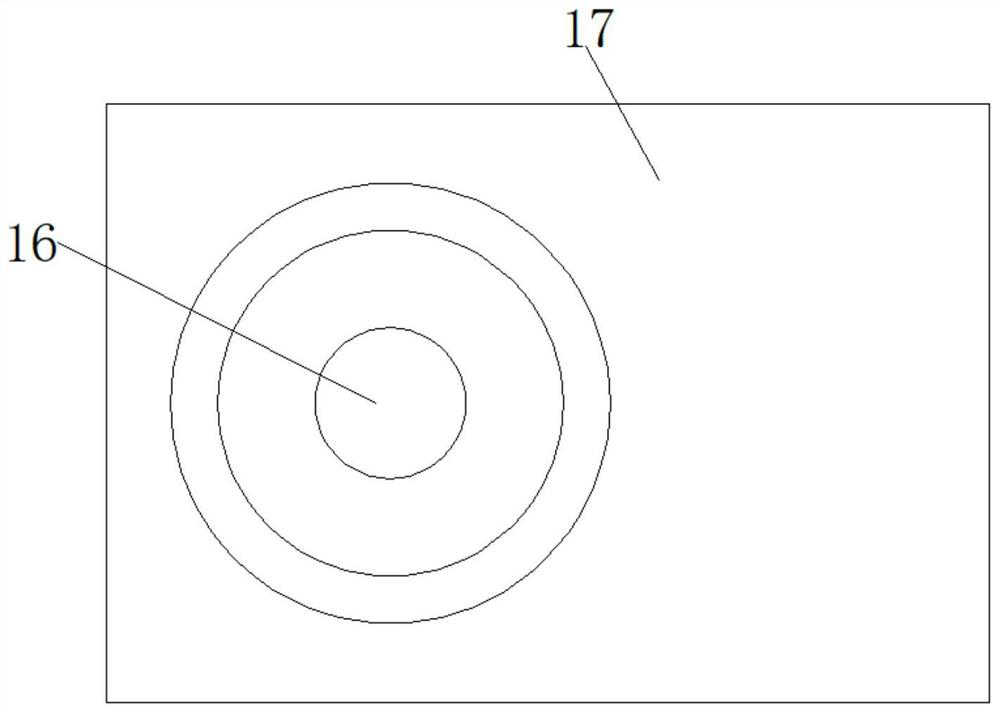

[0034] refer to Figure 1-4 , a monitoring system for manual measurement and detection operations, including a main box 1 and an installation block 2, the installation block 2 is fixedly connected with the outer wall of the main box 1, and the bottom of the main box 1 is provided with a heat dissipation port for controlling the control elements For heat dissipation, a dust-proof net 29 is fixedly inserted in the heat dissipation port to prevent dust from entering the main box body 1. One side of the installation block 2 is fixedly connected with a first motor 3 for driving the gear 6 to rotate. The output of the first motor 3 A supporting sleeve 24 is connected to the rotating shaft on the shaft to prevent the first motor 3 from shaking, and one side of the supporting sleeve 24 is against the inner wall of the slide port 4;

[0035] In the present invention, a sliding port 4 is provided in the mounting block 2, and a slide rail 5 is slidably inserted in the sliding port 4 to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com