Two-dimensional and three-dimensional gas temperature distribution measurement method

A technology of gas temperature distribution and measurement method, which is applied in the direction of radiation pyrometry, thermometer, temperature map, etc., and can solve the problems of large error, correct measurement, and inability to measure two-dimensional temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

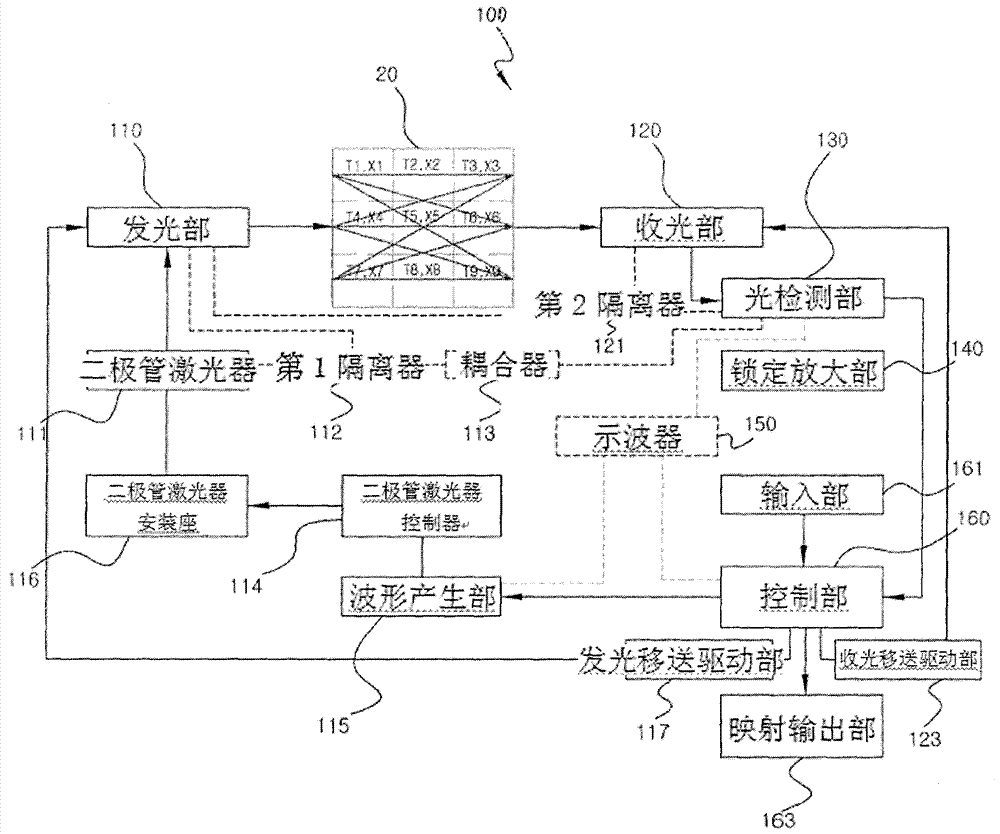

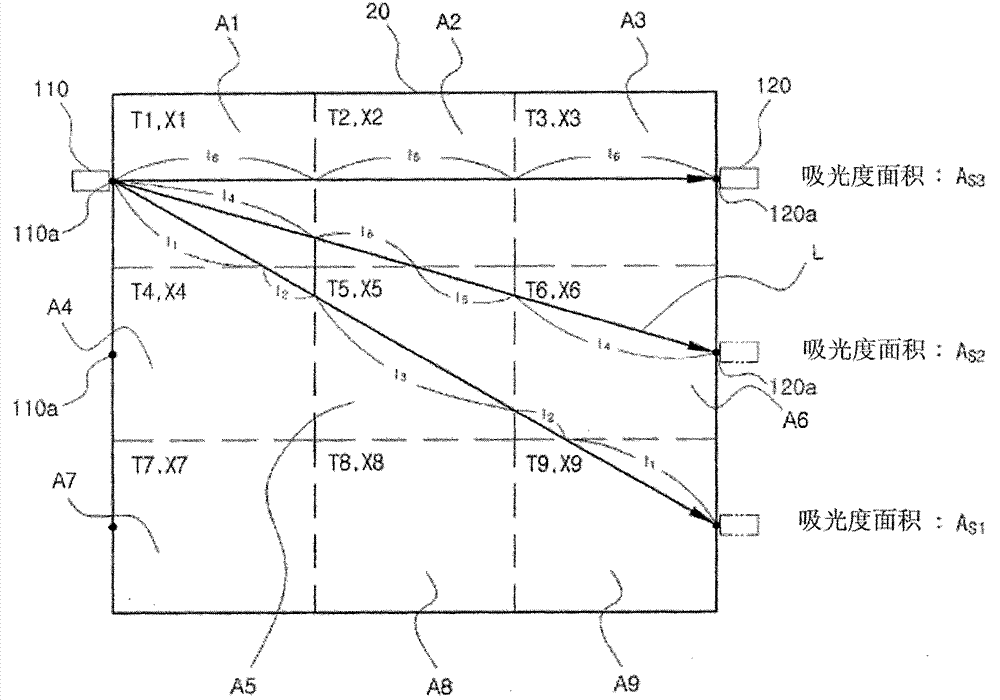

[0042] Such as figure 1 As shown, the measurement system 100 for performing two-dimensional and three-dimensional gas temperature distribution measurement methods according to the present invention includes: a light emitting unit 110 , a light receiving unit 120 and a control unit 160 .

[0043] Such as figure 1 As shown, the light-emitting part 110 emits optical signals to the gas to be measured in a straight-forward manner, which includes: a diode laser 111 emitting laser light, a first isolator 112 to prevent backflow of the laser light, and a coupler for branching the laser light at a required ratio 113, and a diode laser controller 114 that adjusts the intensity and wavelength of the laser.

[0044] The gas to be measured can be, for example, oxygen O 2 .

[0045] The diode laser 111 is connected to the diode laser mount 116 and emits laser light accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com