Method for processing a workpiece by means of a numerically controlled workpiece processing device and workpiece processing device

A digital control and workpiece technology, applied in general control systems, program control, manufacturing tools, etc., can solve problems such as time-consuming, cost-effective, and unfavorable, and achieve the effect of simplified evaluation and efficient optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

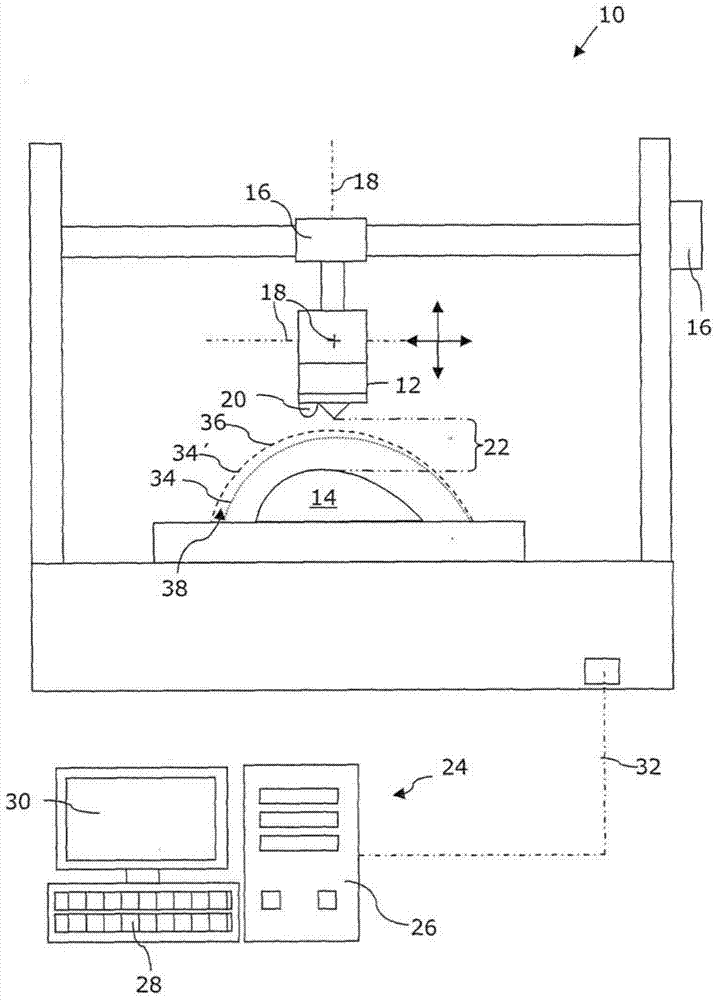

[0026] figure 1 A workpiece processing device 10 embodied as a laser processing device with a (laser) tool 12 is shown in side view. To machine workpiece 14 , tool 12 is movable relative to workpiece 14 along / around a plurality of movement axes 18 by means of a plurality of actuating drives 16 . An optical distance measuring device 20 arranged on the tool 12 is used to measure a corresponding working distance 22 between the tool 12 and the workpiece 14 . The distance measuring device 20 can alternatively also be designed as a capacitive distance measuring device.

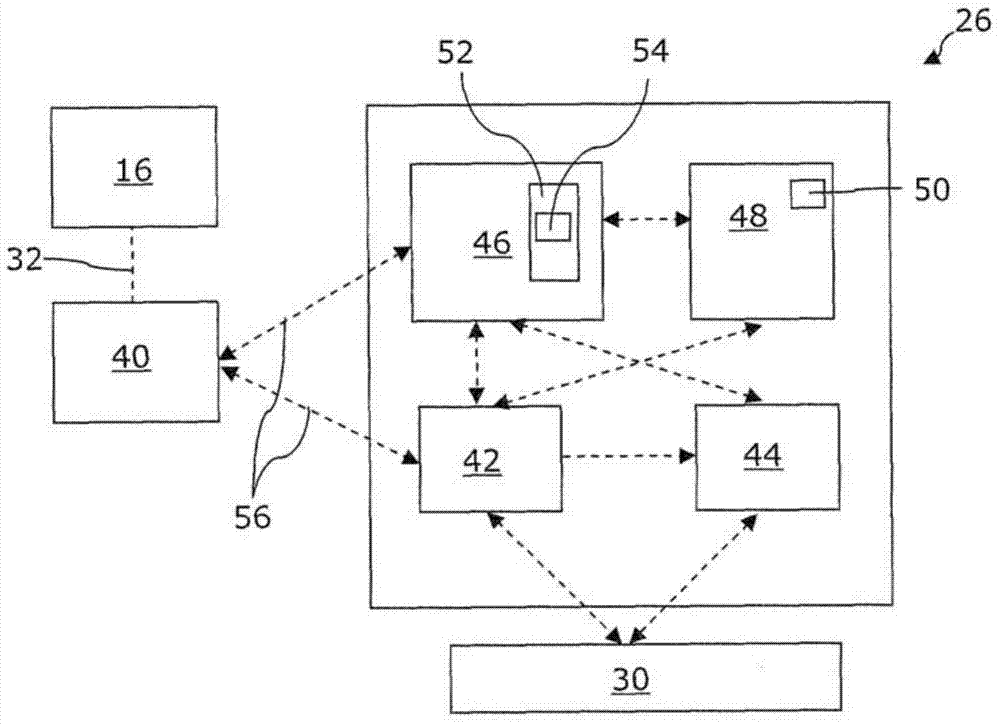

[0027] The numerical control device 24 includes a computer 26 , an input unit 28 connected to the computer 26 and a display 30 . The computer 26 is connected via a control line 32 to the servomotor 16 and the distance measuring device 20 of the tool 12 and is used for the movement control of the tool 12 along the target tool path 34 specified by the control device 24 and for adjusting the working distance 22 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com