A kind of printing equipment for children's hard toy processing

A hard and toy technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increasing labor costs, time-consuming and laborious, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

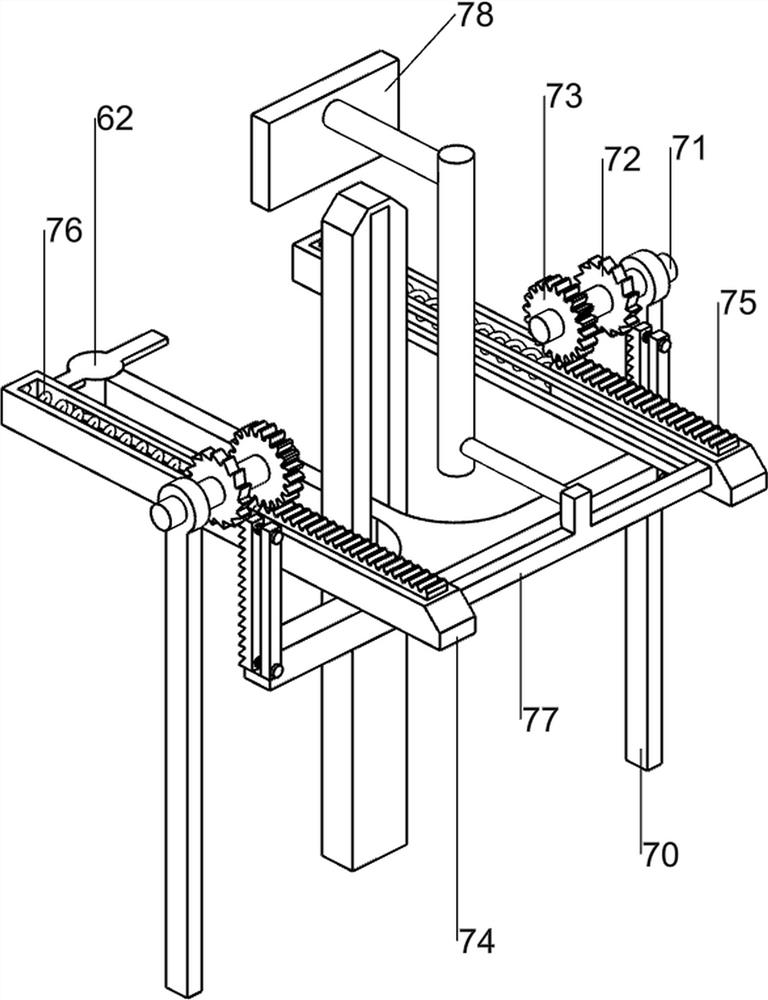

[0074] A printing equipment for processing children's hard toys, such as figure 1 As shown, including a base 1, a pillar 2, a placement complementary color mechanism 3 and a printing mechanism 4, the right part of the base 1 is provided with a support column 2 on four sides, the left side of the base 1 is provided with a placement complementary color mechanism 3, and the placement complementary color mechanism 3 is provided with Printing agency 4.

[0075] When people need to print children's hard toys, place the toy on the complementary coloring mechanism 3, and then move the parts of the printing mechanism 4, so that the parts of the printing mechanism 4 print the toy, and after completion, put the parts of the printing mechanism 4 Move and reset, so that the complementary coloring mechanism 3 is placed to perform complementary coloring on the components of the printing mechanism 4, and finally the toy is taken out.

Embodiment 2

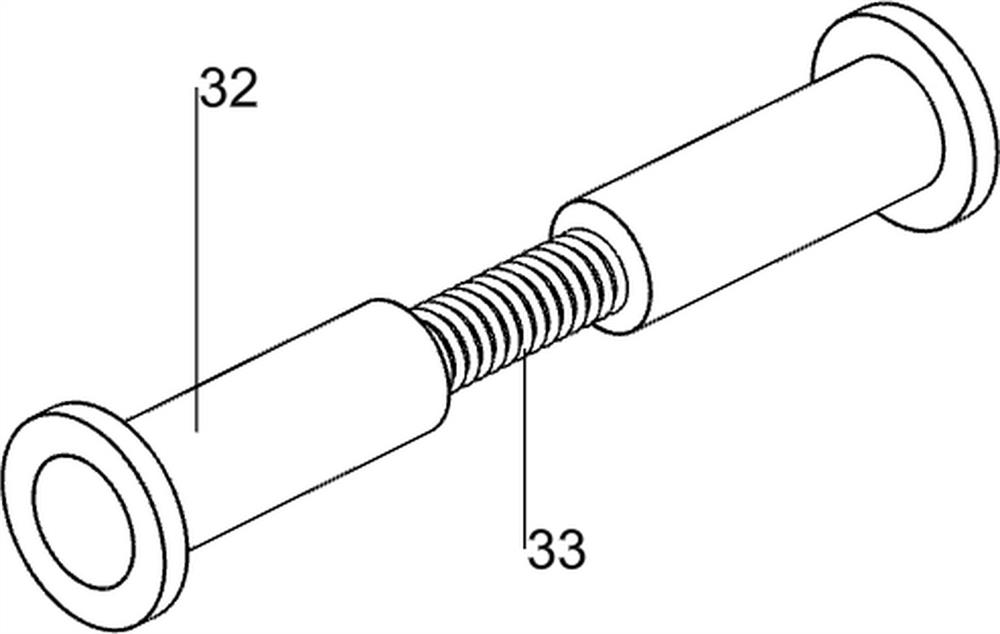

[0077] On the basis of Example 1, as Figure 2-4 As shown, the placement-compensating mechanism 3 includes a first sliding rail 30, a mounting plate 31, a color-correcting device 32 and a first spring 33, and a first sliding rail 30 is connected to both the front and rear sides of the middle of the base 1. The lower part of the first sliding rail 30 A mounting plate 31 is arranged between the two, and a color compensator 32 is slidably connected to the front and rear sides of the mounting plate 31 , and a first spring 33 is arranged between the color compensator 32 .

[0078] When people need to print the children's hard toy, the toy is placed on the mounting plate 31, so that the components of the printing mechanism 4 print the toy, and when the components of the printing mechanism 4 contact the color compensator 32, the color compensator 32 moves inward , so that the first spring 33 is compressed, and the color compensator 32 complements the components of the printing mechan...

Embodiment 3

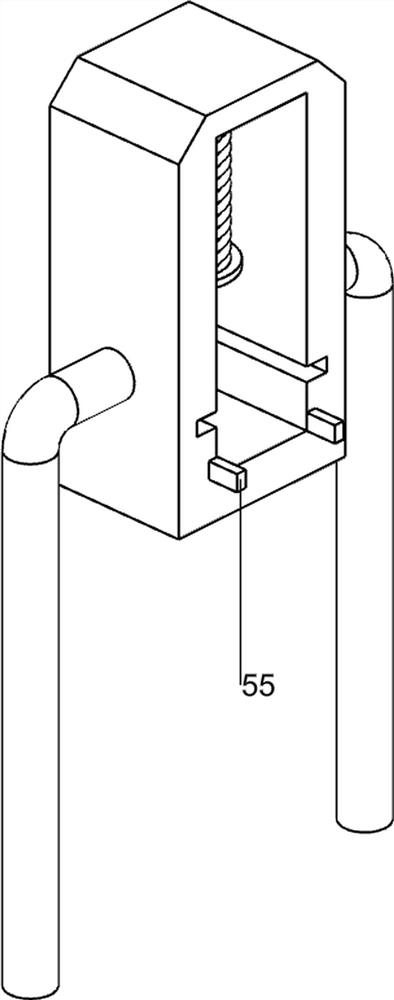

[0082] On the basis of Example 2, as Figure 5-10 As shown, it also includes a blanking mechanism 5. The blanking mechanism 5 includes an L-shaped rod 50, an installation box 51, a hollow cylinder 52, a second spring 53, a lower pressure plate 54 and a baffle 55. Both sides are connected with L-shaped rods 50, and an installation box 51 is arranged between the L-shaped rods 50. The inner top wall of the installation box 51 is provided with a hollow cylinder 52, the bottom of the hollow cylinder 52 is provided with a second spring 53, and the bottom of the second spring 53 is provided with There is a lower pressure plate 54 , and baffles 55 are connected to both the front and rear sides of the lower part of the right side of the installation box 51 .

[0083] When people need to print children's hard toys, move the lower pressure plate 54 upward to make the second spring 53 compressed, then place the toy in the installation box 51, release the hand under the action of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com