Detachable hosiery printing device

A detachable, sock technology, applied in printing, printing press, transfer printing and other directions, can solve the problems of time-consuming and process, save time and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

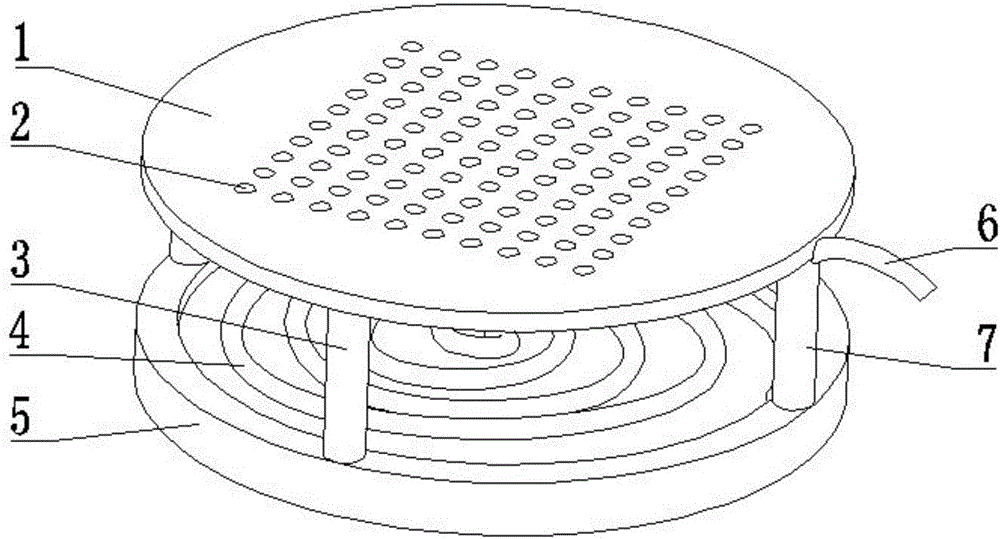

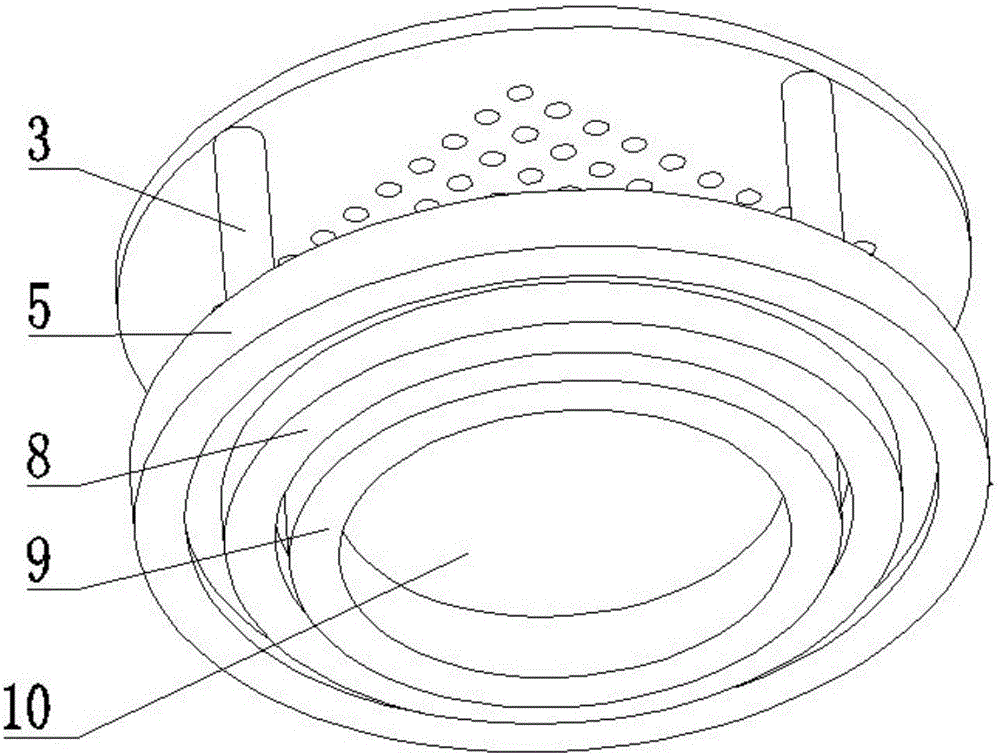

[0023] refer to figure 1 , figure 2 and image 3 , a detachable sock printing device of the present invention, comprising a circular plate 1, a support rod 3, a resistance wire 4, a protective cover 5, an electric wire 6, a heat preservation cover 8, a positioning tube 9 and a metal panel 10, the circular plate 1 is installed On the sock knitting machine, there are densely arranged threaded holes 2 on the circular plate 1; several support rods 3 and wire pipes 7 are arranged at the bottom of the circular plate 1, and the support rods 3 and the wire pipes 7 are on the edge of the circular plate 1. Installation; the inside of the wire pipe 7 is hollow, and the side of the wire pipe 7 is provided with an opening; the metal panel 10 is provided with a protective cover 5, and the resistance wire 4 is installed on the metal panel 10, and the resistance wire 4 is coiled in the protective cover 5 , the tail of the resistance wire 4 is connected to the electric wire 6, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com